Jan . 14, 2025 10:15 Back to list

double pp welding rod

The use of double PP (polypropylene) welding rods has significantly transformed various industries thanks to their exceptional strength and durability. Crafted from polypropylene, a thermoplastic polymer known for its high impact resistance and chemical inertness, these welding rods offer an ideal solution for creating strong, leak-proof seams in a vast range of applications.

Relating to authoritativeness, companies manufacturing double PP welding rods stand behind their products with extensive testing and quality assurances. They often provide detailed data sheets that include tensile strengths, elongation properties, and temperature limits, offering a transparent insight into the product's performance capabilities. These details empower users to make informed decisions, lending credibility and trustworthiness to the manufacturer's claims. In essence, double PP welding rods are more than mere tools; they are integral components that underpin the structural integrity in various high-stakes industries. Their ability to withstand environmental stressors without compromising function underscores their value to professionals committed to excellence in their trades. Thus, investing in high-quality double PP welding rods translates to reliability, safety, and durability — essential pillars upon which industry standards and trust are built. For any enterprise or individual utilizing polypropylene materials, understanding and choosing the right PP welding rods can significantly influence the success and longevity of their operations. As industrial demands continue to evolve, the role of double PP welding rods will undoubtedly become even more critical, with ongoing advancements pushing the boundaries of what's possible in plastic welding technology.

Relating to authoritativeness, companies manufacturing double PP welding rods stand behind their products with extensive testing and quality assurances. They often provide detailed data sheets that include tensile strengths, elongation properties, and temperature limits, offering a transparent insight into the product's performance capabilities. These details empower users to make informed decisions, lending credibility and trustworthiness to the manufacturer's claims. In essence, double PP welding rods are more than mere tools; they are integral components that underpin the structural integrity in various high-stakes industries. Their ability to withstand environmental stressors without compromising function underscores their value to professionals committed to excellence in their trades. Thus, investing in high-quality double PP welding rods translates to reliability, safety, and durability — essential pillars upon which industry standards and trust are built. For any enterprise or individual utilizing polypropylene materials, understanding and choosing the right PP welding rods can significantly influence the success and longevity of their operations. As industrial demands continue to evolve, the role of double PP welding rods will undoubtedly become even more critical, with ongoing advancements pushing the boundaries of what's possible in plastic welding technology.

Share:

Next:

Latest news

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

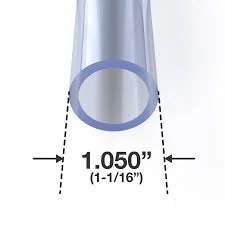

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025