மார்ச் . 04, 2025 01:56 Back to list

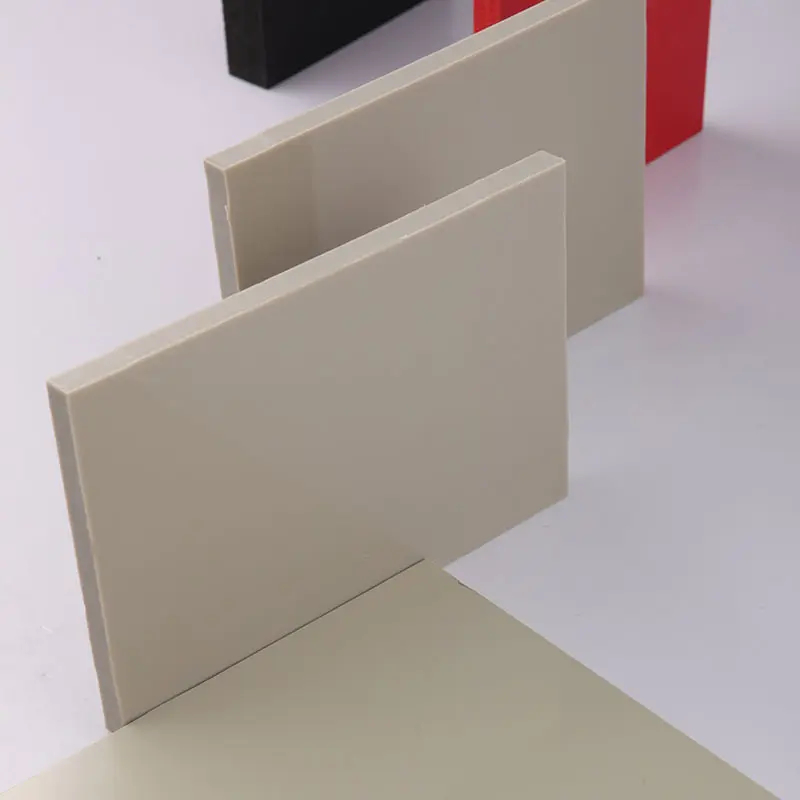

pvc round rod

Navigating the world of industrial materials requires a comprehensive understanding of their properties and applications. PVC round rods, a staple in this domain, have garnered attention due to their versatile nature and utility across various industries. The adaptability of PVC (Polyvinyl Chloride) as a structural component makes these rods a subject of keen interest for manufacturers seeking dependable solutions.

When it comes to machining and fabrication, PVC round rods offer unparalleled ease of use. They can be easily cut, shaped, or welded without compromising their inherent properties, making them a go-to choice for custom applications. Expertise in working with PVC involves understanding its behavior under different machining techniques, ensuring precise fabrication that meets specific project requirements. The sustainability aspect of PVC round rods cannot be overlooked. As industries move towards more eco-conscious practices, PVC’s recyclability comes into play. These rods can be repurposed at the end of their lifecycle, reducing environmental impact and contributing to overall sustainability goals. Understanding this aspect of PVC enhances its desirability in industries increasingly mindful of their ecological footprint. Trust in using PVC round rods is further established through rigorous testing and compliance with industry standards. Manufacturers who produce these rods adhere to strict quality controls, ensuring each product batch meets high standards of performance and safety. These quality assurances bolster confidence among businesses relying on PVC as a core material in their operations. Though the advantages of PVC round rods are significant, awareness of their limitations is also key. They perform optimally within given temperature ranges, and excessive exposure to high temperatures can lead to deformation or structural compromise. Therefore, detailed knowledge of the environmental conditions in which PVC rods operate is crucial for maximizing their effectiveness. In conclusion, PVC round rods are an indispensable material in today’s industrial landscape. Their unique combination of physical and chemical properties makes them a trusted choice across many sectors. The expertise in leveraging these rods hinges on understanding their multifaceted benefits and limitations, ensuring they are applied in ways that best maximize their potential. Their continued application in industrial settings is a testament to their reliability and the confidence industries place in their use.

When it comes to machining and fabrication, PVC round rods offer unparalleled ease of use. They can be easily cut, shaped, or welded without compromising their inherent properties, making them a go-to choice for custom applications. Expertise in working with PVC involves understanding its behavior under different machining techniques, ensuring precise fabrication that meets specific project requirements. The sustainability aspect of PVC round rods cannot be overlooked. As industries move towards more eco-conscious practices, PVC’s recyclability comes into play. These rods can be repurposed at the end of their lifecycle, reducing environmental impact and contributing to overall sustainability goals. Understanding this aspect of PVC enhances its desirability in industries increasingly mindful of their ecological footprint. Trust in using PVC round rods is further established through rigorous testing and compliance with industry standards. Manufacturers who produce these rods adhere to strict quality controls, ensuring each product batch meets high standards of performance and safety. These quality assurances bolster confidence among businesses relying on PVC as a core material in their operations. Though the advantages of PVC round rods are significant, awareness of their limitations is also key. They perform optimally within given temperature ranges, and excessive exposure to high temperatures can lead to deformation or structural compromise. Therefore, detailed knowledge of the environmental conditions in which PVC rods operate is crucial for maximizing their effectiveness. In conclusion, PVC round rods are an indispensable material in today’s industrial landscape. Their unique combination of physical and chemical properties makes them a trusted choice across many sectors. The expertise in leveraging these rods hinges on understanding their multifaceted benefits and limitations, ensuring they are applied in ways that best maximize their potential. Their continued application in industrial settings is a testament to their reliability and the confidence industries place in their use.

Share:

Next:

Latest news

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025

-

Premium PVC Pipe Fitting Supplier – Durable & Leak-Proof Solutions

NewsJul.30,2025