Novemba . 09, 2024 22:20 Back to list

Exploring the Benefits and Applications of CPVC Board in Construction

Understanding CPVC Board Benefits, Applications, and Characteristics

In the realm of construction materials, CPVC (Chlorinated Polyvinyl Chloride) board has emerged as a notable contender boasting a range of advantages that cater to both residential and commercial applications. As a type of thermoplastic, CPVC has been modified from standard PVC, enabling it to withstand higher temperatures and demonstrating enhanced chemical resistance. This article explores the benefits, applications, and unique characteristics of CPVC boards.

What is CPVC Board?

CPVC boards are made from a thermoplastic polymer characterized by its increased chlorine content compared to regular PVC. This chlorine content imparts exceptional heat tolerance and strength, making CPVC boards a versatile material option across various industries. Frequently available in sheets and panels, these boards can be fabricated into various shapes and sizes, thereby offering tremendous flexibility for diverse applications.

Benefits of CPVC Board

One of the significant advantages of CPVC boards is their remarkable resistance to corrosive substances. In environments where exposure to harsh chemicals is commonplace, CPVC boards outperform traditional materials like wood or metal, which may deteriorate over time. This feature makes CPVC particularly attractive for use in laboratories, chemical plants, and even in commercial kitchens.

In addition to chemical resistance, CPVC boards exhibit excellent thermal stability. They can endure temperatures up to 200°F (approximately 93°C), making them an ideal choice for hot water systems and applications involving elevated temperatures. This thermal resilience is paramount in preventing warping or deformation, which often plagues lower-grade materials when exposed to heat.

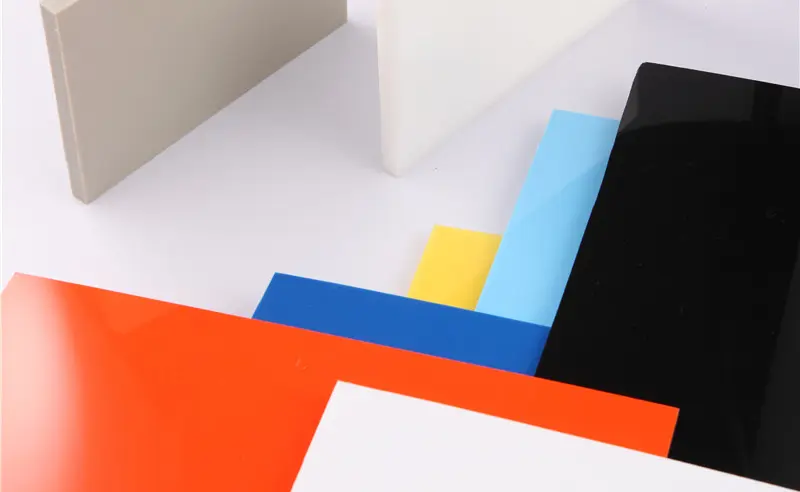

cpvc board

Another noteworthy benefit is the low thermal conductivity of CPVC. This property enables CPVC boards to maintain their temperature without dissipating heat quickly, which is advantageous in insulation applications. Additionally, CPVC boards are lightweight compared to alternatives, leading to easier handling and installation, which can significantly reduce labor costs on construction sites.

Applications of CPVC Board

CPVC boards find applications in various sectors, due in part to their versatility. In the construction and plumbing industries, they are utilized for manufacturing piping systems, valves, and fittings. Their ability to withstand high temperatures and resist corrosion makes them ideal for both residential and commercial plumbing infrastructure.

In the realm of electrical applications, CPVC boards serve as excellent insulators. Their non-conductive nature ensures that electrical installations remain safe and efficient, often being used in cable ducts and conduit systems. This application is especially beneficial in environments prone to moisture, where traditional materials might corrode or degrade.

Beyond industrial uses, CPVC boards also hold promise in the field of architecture and design. They can be employed to create decorative wall panels and furniture due to their aesthetic appeal and ease of fabrication. Additionally, CPVC boards can be used in signage and displays, leveraging their ability to be printed on or painted.

Conclusion

In conclusion, CPVC boards represent a remarkable innovation in the world of construction materials. Their enhanced properties, including superior chemical resistance, high thermal stability, and lightweight characteristics, make them suitable for a wide range of applications—from plumbing and electrical installations to architectural designs. As industries continue to seek durable, efficient, and versatile materials, the popularity of CPVC boards is likely to increase. Whether one is involved in industrial projects or home renovations, understanding the benefits and applications of CPVC boards can lead to more informed and effective material choices, ensuring longevity and reliability in various constructions.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025