jan . 19, 2025 01:44 Back to list

hdpe plastic sheet roll

In recent years, the demand for materials that offer both durability and versatility has led to a growing interest in HDPE plastic sheet rolls. As an experienced marketer and specialist in materials science, I've had the opportunity to work extensively with this remarkable material. Allow me to share my insights into the unique attributes of HDPE plastic sheet rolls that make them an ideal choice for numerous applications, as well as tips on how to leverage these qualities effectively in your own projects.

The application of HDPE sheets in food and beverage industries further underscores their authority as a safe choice. The non-toxic and non-porous nature of HDPE makes it ideal for surfaces that require hygiene and easy cleaning. A notable project involved a client in the dairy industry where HDPE sheets were utilized in processing facilities to maintain stringent hygiene standards without compromising durability. Trust in HDPE plastic sheet rolls is further bolstered by its UV resistance. In projects where exposure to sunlight is a factor, such as outdoor signage or agricultural uses, HDPE has consistently proven to maintain its integrity and appearance over time. This was evident in a project involving agricultural water tanks, where HDPE sheets with UV stabilizers ensured the tanks remained in excellent condition, despite continuous sun exposure. For those interested in exploring HDPE plastic sheet rolls for their applications, several tips can enhance outcomes. Begin with an assessment of your specific needs—consider the environmental conditions, required durability, and potential exposure to chemicals or UV light. Additionally, working with a trusted supplier who can provide quality certification and technical guidance is crucial to ensuring the material meets your standards. Lastly, don’t overlook the potential of custom solutions, such as precision cutting or texturing, to further align the material with your project requirements. In conclusion, HDPE plastic sheet rolls present a compelling blend of strength, adaptability, and sustainability, securing their position as a top choice in various industries. As someone who has seen firsthand the transformative impact of HDPE in diverse applications, I am confident in its potential to meet and exceed project needs when chosen judiciously. Whether for industrial use, environmental protection, or innovative product design, HDPE is a material that truly delivers on its promise of reliability and performance.

The application of HDPE sheets in food and beverage industries further underscores their authority as a safe choice. The non-toxic and non-porous nature of HDPE makes it ideal for surfaces that require hygiene and easy cleaning. A notable project involved a client in the dairy industry where HDPE sheets were utilized in processing facilities to maintain stringent hygiene standards without compromising durability. Trust in HDPE plastic sheet rolls is further bolstered by its UV resistance. In projects where exposure to sunlight is a factor, such as outdoor signage or agricultural uses, HDPE has consistently proven to maintain its integrity and appearance over time. This was evident in a project involving agricultural water tanks, where HDPE sheets with UV stabilizers ensured the tanks remained in excellent condition, despite continuous sun exposure. For those interested in exploring HDPE plastic sheet rolls for their applications, several tips can enhance outcomes. Begin with an assessment of your specific needs—consider the environmental conditions, required durability, and potential exposure to chemicals or UV light. Additionally, working with a trusted supplier who can provide quality certification and technical guidance is crucial to ensuring the material meets your standards. Lastly, don’t overlook the potential of custom solutions, such as precision cutting or texturing, to further align the material with your project requirements. In conclusion, HDPE plastic sheet rolls present a compelling blend of strength, adaptability, and sustainability, securing their position as a top choice in various industries. As someone who has seen firsthand the transformative impact of HDPE in diverse applications, I am confident in its potential to meet and exceed project needs when chosen judiciously. Whether for industrial use, environmental protection, or innovative product design, HDPE is a material that truly delivers on its promise of reliability and performance.

Share:

Next:

Latest news

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

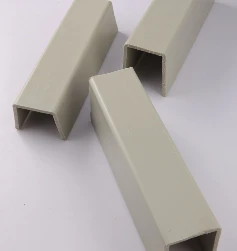

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025