Thepa ea 'Mele

| Test Standard

(QB/T 2490-2000) |

Yuniti |

Boleng bo Tlwaelehileng |

|

| Ea nama |

|

|

|

| Botenya |

0.94-0.96 |

g/cm3 |

0.962 |

| Mechini |

|

|

|

| Tensile Strength (Bolelele/Bophara) |

≥22 |

Mpa |

30/28 |

| Elongation |

—– |

% |

8 |

| Notch Impact Strength

(Bolelele/Bophara) |

≥18

|

KJ/㎡ |

18.36/18.46 |

| Mocheso |

|

|

|

| Vicat Softening Temperature |

—–

|

°C |

80 |

| Mocheso Deflection mocheso |

—– |

°C |

68 |

| Motlakase |

|

|

|

| Ho hanyetsa Molumo |

|

ohm·cm |

≥1015 |

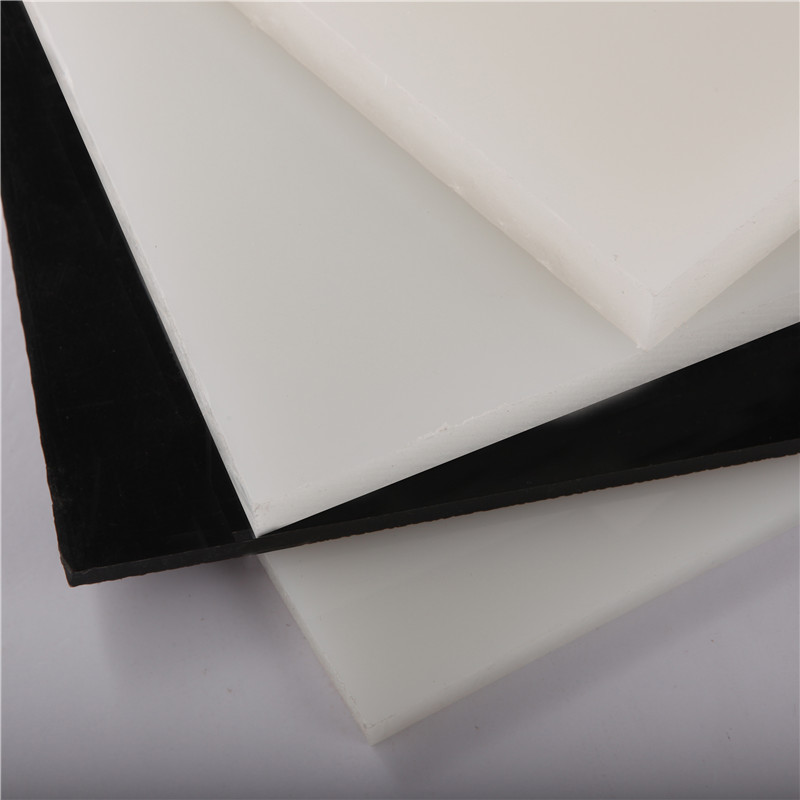

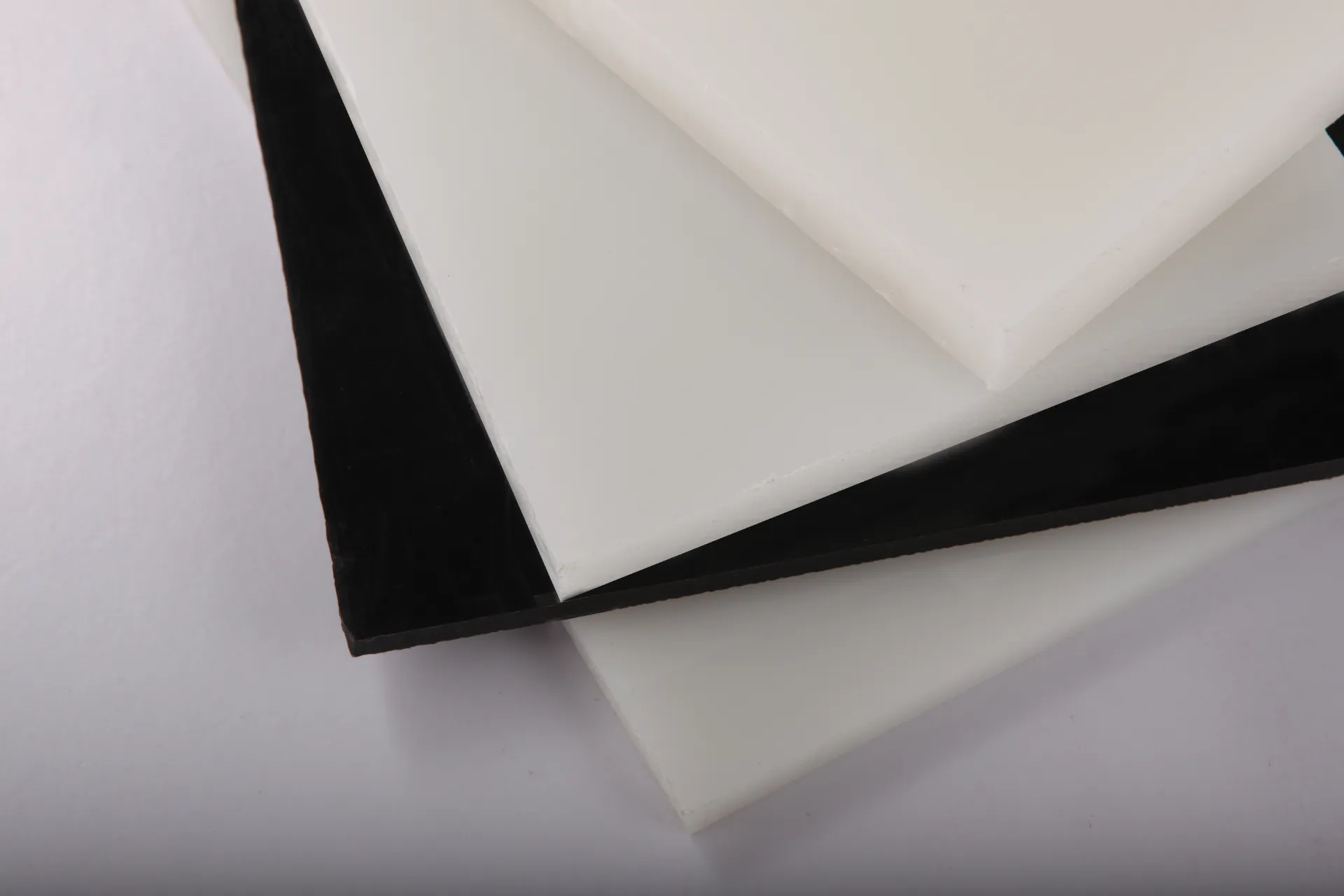

Tlhaloso ea Sehlahisoa

HDPE e sebelisoa lits'ebetsong le liindastering tse fapaneng moo ho hanyetsanang le tšusumetso e ntle haholo, matla a phahameng a tsitsipano, ho monya mongobo o tlase le thepa ea ho hanyetsa lik'hemik'hale le kutu. Mme PE e na le thepa e ntle ea ho kenya letsoho 'me e bonolo ho e cheseletsa.

Letlapa le letšo la HDPE le entsoe ka HDPE e nang le poleiti e khethehileng ea 'mala. Lintho tse tala tsa HDPE li tšoeu, tse ntšo li kenngoa carbon black. Karolo e ka sehloohong ea carbon black ke anti-ultraviolet, carbon black e ka thibela ka katleho tšenyo ea ultraviolet ho ketane ea molek'hule ea polyethylene. Letlapa le letšo la HDPE le fana ka boiketlo bo boholo bakeng sa tšebeliso ea moea o bulehileng, empa hape le ka patoa hore le sebelisoe, ha le ntse le kopana le litlhoko tsa ts'ebetso ea bophelo bo botle.

Litšobotsi

e hanyetsanang le UV;

E thibela ho bola;

Ha ho na metsi;

Non-caking & sticking;

Ho hanyetsa mocheso o tlase;

Khahlanong le lik'hemik'hale tse babatsehang;

High abrasion le ho apara ho hanyetsa;

E entsoe habonolo bakeng sa tšebeliso ea boenjiniere.

Setifikeiti sa leqephe la HDPE

Setifikeiti sa ROHS

Bophahamo ba sehlahisoa

1. High utilization rate, long service cycle, good chemical effect.

2. Strong and durable, good density and stretch.

3. Complete specifications, special specifications can be customized.

4. Large factories produce boards with guaranteed quality.

5. Preferential price, fast delivery, pre-sale and after-sales service guaranteed.

Lisebelisoa

Mabele: polokelo ya dijo kapa lesela la chute.

Morafo: poleiti ea sieve, li-chute linings, roala karolo e thibelang bonding.

Ts'ebetso ea mashala: poleiti ea sieve, filthara, chute ea mashala ea U-underground.

Boenjiniere ba Lik'hemik'hale: Ho senya le ho roala likarolo tsa mochine.

Matla a futhumatsang: ho tšoara mashala, ho boloka mashala, ho boloka lesela la chute.

Indasteri ea lijo: lebili le bōpehileng joaloka naleli, sekoti sa botlolo sa phetiso ea nako, li-bearings, lirolara tse tataisang, litataiso, li-slide blocks, jj.