дец . 10, 2024 17:10 Back to list

triangle pp welding rod

Triangle PP Welding Rods A Comprehensive Guide to Choosing and Using Them

Welding is an essential process in various industries, from construction to manufacturing. Among the numerous materials and methods used in welding, one notable product that has gained popularity is the Triangle PP welding rod. This article aims to provide an insightful overview of Triangle PP welding rods, their characteristics, applications, and best practices for use.

What are Triangle PP Welding Rods?

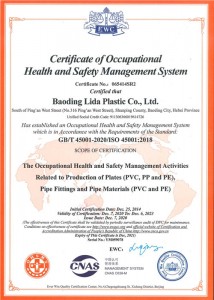

Triangle PP welding rods are specifically designed for welding polypropylene (PP) materials. Polypropylene is a thermoplastic polymer widely used in diverse applications due to its excellent chemical resistance, light weight, and mechanical strength. The Triangle brand is known for producing high-quality welding products, and their PP welding rods are no exception.

These rods have been engineered to ensure strong bonding between polypropylene components, making them particularly useful in industries such as automotive, textiles, packaging, and medical devices. The rods come in various diameters and lengths to cater to different welding requirements. Typically, they are available in both solid and hollow forms.

Key Characteristics

1. High Thermal Resistance Triangle PP welding rods can withstand high temperatures, which is crucial during the welding process and the end-use of the welded product.

2. Chemical Resistance One of the main advantages of polypropylene is its resistance to a wide range of chemicals, including acids and bases. This property is preserved in Triangle PP welding rods, making them suitable for applications that involve exposure to harsh substances.

3. Ease of Use These rods are designed for compatibility with various welding techniques, including extrusion and hot air welding. Their consistent melting point allows for easy and efficient welding processes.

4. Strength and Durability Welds made with Triangle PP rods exhibit high tensile strength, ensuring that the final product is robust and long-lasting.

Applications

The versatility of Triangle PP welding rods allows them to be used in multiple fields

triangle pp welding rod

- Automotive Industry They are used to join parts of vehicles, particularly in interiors and under-the-hood components, due to their lightweight properties and resistance to heat and chemicals.

- Packaging Many packaging materials, such as containers and films, are made of polypropylene. Triangle welding rods can effectively create strong seals to enhance product integrity.

- Textile Industry In the manufacturing of synthetic textiles, these rods are used to weld and seal fabric components, ensuring durability and resistance to wear.

- Medical Devices In the healthcare sector, where cleanliness and sterility are paramount, Triangle PP welding rods are often employed to fabricate medical devices and containers.

Best Practices for Use

To achieve optimal results with Triangle PP welding rods, consider the following best practices

1. Surface Preparation Ensure that the surfaces to be welded are clean and free from contaminants, such as oil or dirt. Proper surface preparation ensures a strong bond.

2. Adjust Temperature Settings Different welding jobs may require variations in temperature settings. Consult the manufacturer's guidelines to select the appropriate temperature for the specific rod being used.

3. Welding Technique Familiarize yourself with the welding technique best suited for your application, whether it's extrusion, hot air, or another method. Mastery of the technique will enhance the quality of the weld.

4. Post-Welding Inspection Once the welding is complete, inspect the weld joint for defects or weaknesses. Proper inspection can prevent future failures and enhance safety.

In conclusion, Triangle PP welding rods are a valuable resource for industries requiring robust and durable bonding solutions for polypropylene materials. Their unique characteristics and versatility make them an excellent choice for applications ranging from automotive assembly to medical device manufacturing. By adhering to best practices, welders can ensure high-quality results, maximizing the benefits these welding rods offer.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025