Oct . 19, 2024 10:43 Back to list

hdpe welding rod 5mm

Understanding HDPE Welding Rods A Key Component in Plastic Fabrication

High-Density Polyethylene (HDPE) welding rods are integral to various industrial applications, particularly in the plastic fabrication industry. Composed of high-density polyethylene, these rods are specifically designed for welding and repairing HDPE materials, which are widely used in numerous industries due to their durability, resistance to chemicals, and lightweight properties. This article delves into the significance of 5mm HDPE welding rods, their applications, and the welding techniques employed.

What Are HDPE Welding Rods?

HDPE welding rods are made from the same thermoplastic material used in HDPE products, ensuring compatibility during the welding process. These rods come in various diameters, with 5mm rods being one of the most common sizes used in moderate to large-scale applications. The rods exhibit excellent tensile strength, allowing for robust joints and repairs that are critical in maintaining the integrity of HDPE structures.

Applications of 5mm HDPE Welding Rods

5mm HDPE welding rods are versatile and suitable for numerous applications across various sectors, including

1. Water and Waste Management HDPE is often used in piping systems for water supply and wastewater management due to its resistance to corrosion and chemicals. Welding rods are utilized to repair leaks or fabricate new pipe sections, ensuring a secure and durable connection.

2. Agriculture In agricultural settings, HDPE is used for irrigation systems, tanks, and other equipment. Welding rods enable farmers to repair broken components efficiently, minimizing downtime and maintaining productivity.

3. Marine Applications Due to its excellent resistance to moisture and UV rays, HDPE is widely used in marine environments for building docks, barges, and storage tanks. Welding rods help create strong joints that can endure the harsh marine conditions.

hdpe welding rod 5mm

4. Construction In the construction industry, HDPE is used for various applications, from geotechnical installations to protective barriers. Welding rods facilitate the creation of custom-sized structures and repairs, enhancing overall project efficiency.

Welding Techniques for HDPE

Welding HDPE with 5mm rods can be accomplished using various techniques, each suited to different applications and project requirements. The most common methods include

1. Extrusion Welding This method involves using a welding machine that heats the HDPE welding rod and extrudes it into the joint. It is effective for filling gaps and creating strong, uniform welds.

2. Butt Welding This technique joins two pieces of HDPE by heating their edges until they reach a molten state and then pressing them together. It is ideal for creating seamless joints in piping applications.

3. Socket Welding In this method, the welding rod is inserted into a pre-heated socket joint where the two pieces meet. The process allows for strong connections in complex shapes.

Conclusion

HDPE welding rods, particularly the 5mm variety, are essential components in the maintenance, repair, and construction of HDPE products. Their versatility and strength make them invaluable across numerous industries, from agriculture to marine applications. Understanding the different welding techniques and applications of these rods enables professionals to choose the appropriate methods for their specific projects, ensuring durability and efficiency. As industries increasingly rely on HDPE for its properties, the demand for HDPE welding rods is likely to continue growing, solidifying their place as a cornerstone in plastic fabrication.

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

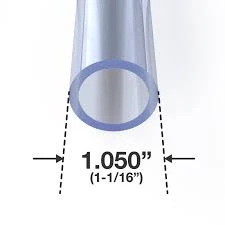

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025