Feb . 12, 2025 18:19 Back to list

hdpe sheet

High-Density Polyethylene (HDPE) sheets have become an indispensable component across various industries, thanks to their unmatched versatility, durability, and affordability. Their wide-ranging applications, from construction to consumer products, underscore the attributes that make them a popular choice. This article delves into the extensive uses and benefits of HDPE sheets, empowering businesses to leverage their full potential effectively.

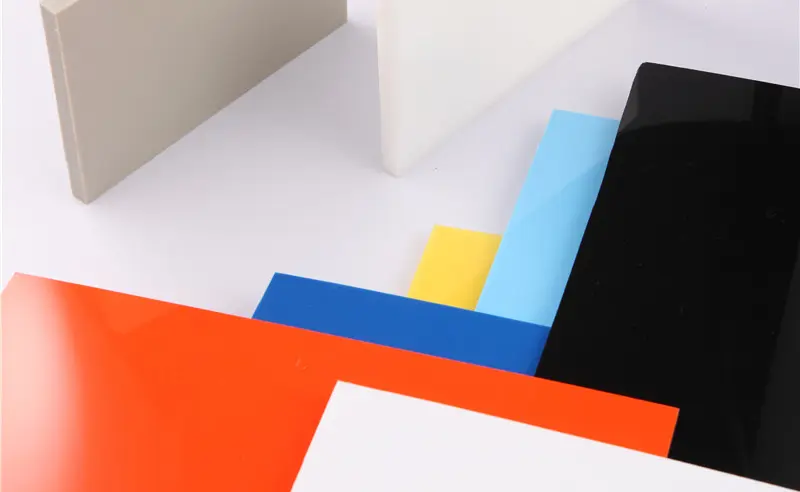

Processing and installation of HDPE sheets are relatively straightforward due to their lightweight nature. Unlike metals or other dense materials, HDPE sheets can be easily maneuvered, reducing labor costs and equipment needs. For large-scale applications, this ease of handling translates into significant time and cost savings, presenting a compelling advantage for project managers and engineers. In industries where chemical exposure is common, such as in chemical processing plants, HDPE sheets are favored for their resistance to most acids and bases. This chemical resilience ensures that they degrade less over time, maintaining structural integrity and safety. The negligible maintenance they require further lowers long-term costs, underpinning their economic viability. When considering the aesthetic aspect, HDPE sheets are available in a variety of colors and finishes. This allows businesses to incorporate them into projects where visual appeal is essential without sacrificing functional integrity. From outdoor playgrounds to visually appealing commercial spaces, HDPE sheets balance aesthetic requirements with durability. In terms of regulatory compliance, HDPE sheets meet many industry standards governing safety and performance. Companies using HDPE sheets can confidently adhere to these standards, knowing that their chosen material is endorsed by relevant authorities. This compliance not only aids in securing approvals and certifications but also boosts consumer confidence. Ultimately, HDPE sheets represent a synergistic blend of performance, economic efficiency, and environmental sensitivity. Their multifaceted applications are a testament to their adaptability and suitability for a spectrum of industrial needs. Choosing HDPE sheets is an investment in a material that delivers value, underlines dependability, and aligns with both immediate and future-oriented business strategies. In conclusion, industries seeking a durable, eco-friendly, and versatile material will find that HDPE sheets offer unmatched advantages. From providing structural integrity to supporting environmental initiatives, they stand as a cornerstone in manufacturing and construction sectors. Businesses embracing HDPE sheets not only enhance their operational efficiency but also contribute to a sustainable future, positioning themselves at the forefront of responsible and innovative industrial practices.

Processing and installation of HDPE sheets are relatively straightforward due to their lightweight nature. Unlike metals or other dense materials, HDPE sheets can be easily maneuvered, reducing labor costs and equipment needs. For large-scale applications, this ease of handling translates into significant time and cost savings, presenting a compelling advantage for project managers and engineers. In industries where chemical exposure is common, such as in chemical processing plants, HDPE sheets are favored for their resistance to most acids and bases. This chemical resilience ensures that they degrade less over time, maintaining structural integrity and safety. The negligible maintenance they require further lowers long-term costs, underpinning their economic viability. When considering the aesthetic aspect, HDPE sheets are available in a variety of colors and finishes. This allows businesses to incorporate them into projects where visual appeal is essential without sacrificing functional integrity. From outdoor playgrounds to visually appealing commercial spaces, HDPE sheets balance aesthetic requirements with durability. In terms of regulatory compliance, HDPE sheets meet many industry standards governing safety and performance. Companies using HDPE sheets can confidently adhere to these standards, knowing that their chosen material is endorsed by relevant authorities. This compliance not only aids in securing approvals and certifications but also boosts consumer confidence. Ultimately, HDPE sheets represent a synergistic blend of performance, economic efficiency, and environmental sensitivity. Their multifaceted applications are a testament to their adaptability and suitability for a spectrum of industrial needs. Choosing HDPE sheets is an investment in a material that delivers value, underlines dependability, and aligns with both immediate and future-oriented business strategies. In conclusion, industries seeking a durable, eco-friendly, and versatile material will find that HDPE sheets offer unmatched advantages. From providing structural integrity to supporting environmental initiatives, they stand as a cornerstone in manufacturing and construction sectors. Businesses embracing HDPE sheets not only enhance their operational efficiency but also contribute to a sustainable future, positioning themselves at the forefront of responsible and innovative industrial practices.

Share:

Next:

Latest news

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025