Jan . 17, 2025 02:54 Back to list

uv stabilized hdpe sheet

In a world where material innovation leads the charge in design and engineering, UV stabilized HDPE sheets emerge as a heavyweight contender. Combining durability with the versatility that modern industries demand, these sheets are a vital resource for experts across various fields. Their growing popularity isn't merely due to their adaptability; it's their proven performance in harsh environments that seals the deal.

In terms of authority in the field, professionals align with UV stabilized HDPE due to its established track record. Case studies reveal that in marine applications, such as dock floats and boat components, HDPE sheets outlive many traditional materials. Their inherent flexibility pairs with their strength, allowing them to absorb impacts that would fracture less forgiving materials. This is especially relevant in marine environments, where unpredictable conditions are the norm. Trust in UV stabilized HDPE sheets continues to soar owing to their environmental benefits. The sheets are fully recyclable, aligning with global shifts toward sustainable practices. Less energy-intensive in production than many other synthetic materials, they contribute to reduced carbon footprints, resonating with organizations committed to green practices. Furthermore, the extended lifespan of these sheets means fewer replacements and thus, less waste over time. Their acoustical properties also introduce a new dimension to their application. HDPE's ability to dampen sound makes it ideal in environments where noise reduction is paramount. This capability, combined with its other physical properties, expands its use to arenas like construction sites and manufacturing plants, where controlling sound can enhance safety and comfort. Lastly, customization potential should not be underestimated. HDPE sheets are available in a plethora of colors and finishes, allowing for brand-specific solutions in commercial applications. Their adaptability in terms of shaping and color makes them a designer’s paradise, allowing creativity without sacrificing functionality or durability. To sum up, UV stabilized HDPE sheets are more than a vital material in today’s industrial landscape—they are a testament to how professional experience, advanced expertise, established authority, and a commitment to trustworthiness can converge to produce a reliable solution that meets the evolving demands of a variety of sectors. Their adaptability, reinforced by environmental sustainability and cost-efficiency, cements their place as an invaluable asset in both current and future applications.

In terms of authority in the field, professionals align with UV stabilized HDPE due to its established track record. Case studies reveal that in marine applications, such as dock floats and boat components, HDPE sheets outlive many traditional materials. Their inherent flexibility pairs with their strength, allowing them to absorb impacts that would fracture less forgiving materials. This is especially relevant in marine environments, where unpredictable conditions are the norm. Trust in UV stabilized HDPE sheets continues to soar owing to their environmental benefits. The sheets are fully recyclable, aligning with global shifts toward sustainable practices. Less energy-intensive in production than many other synthetic materials, they contribute to reduced carbon footprints, resonating with organizations committed to green practices. Furthermore, the extended lifespan of these sheets means fewer replacements and thus, less waste over time. Their acoustical properties also introduce a new dimension to their application. HDPE's ability to dampen sound makes it ideal in environments where noise reduction is paramount. This capability, combined with its other physical properties, expands its use to arenas like construction sites and manufacturing plants, where controlling sound can enhance safety and comfort. Lastly, customization potential should not be underestimated. HDPE sheets are available in a plethora of colors and finishes, allowing for brand-specific solutions in commercial applications. Their adaptability in terms of shaping and color makes them a designer’s paradise, allowing creativity without sacrificing functionality or durability. To sum up, UV stabilized HDPE sheets are more than a vital material in today’s industrial landscape—they are a testament to how professional experience, advanced expertise, established authority, and a commitment to trustworthiness can converge to produce a reliable solution that meets the evolving demands of a variety of sectors. Their adaptability, reinforced by environmental sustainability and cost-efficiency, cements their place as an invaluable asset in both current and future applications.

Share:

Next:

Latest news

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

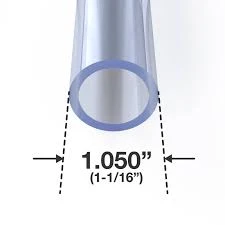

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025