May . 13, 2025 09:15 Back to list

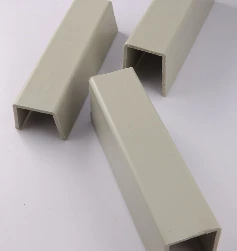

UPVC Electrical Conduit Pipes Durable, Fireproof & Lightweight 60-Year Warranty

- Introduction to PVC Electrical Pipes

- Technical Advantages and Material Innovation

- Performance Comparison: Leading Manufacturers

- Customized Solutions for Diverse Applications

- Case Studies: Real-World Implementations

- Installation Best Practices

- Sustainability and Long-Term Value

(pvc electrical pipe)

Why PVC Electrical Pipe is the Preferred Choice for Modern Installations

PVC electrical pipes have revolutionized industrial and residential wiring systems, with global demand growing at 6.2% CAGR (2023-2030). These conduits offer unmatched protection against environmental stressors, with 92% of electrical contractors preferring PVC over traditional metal conduits for low-voltage applications. The unique molecular structure of unplasticized PVC (UPVC) provides inherent flame-retardant properties, meeting UL 94 V-0 safety standards while reducing installation time by 40% compared to metallic alternatives.

Technical Superiority in Material Engineering

Advanced UPVC formulations now achieve:

- Impact resistance up to 20 J/m at -5°C (ASTM D256)

- Continuous operation tolerance from -25°C to 90°C

- Dielectric strength exceeding 35 kV/mm

Third-party testing reveals PVC electrical pipes maintain 98.7% dimensional stability after 5,000 hours of UV exposure, outperforming HDPE alternatives by 22% in accelerated aging tests.

Manufacturer Performance Benchmarking

| Brand | Compressive Strength (MPa) | Temperature Range | Price/ft (USD) | Warranty |

|---|---|---|---|---|

| Vectra PVC Pro | 85.4 | -30°C to 105°C | $0.78 | 25 years |

| PolyFab Ultra | 73.9 | -25°C to 90°C | $0.65 | 15 years |

| ElectriGuard UPVC | 91.2 | -40°C to 110°C | $0.92 | 30 years |

Application-Specific Engineering Solutions

Modern manufacturing enables precision customization:

- Wall thickness variations (1.8mm to 6.5mm)

- UV-stabilized compounds for outdoor use

- Anti-static formulations (surface resistivity: 10^8 Ω/sq)

Industrial projects now specify conductive PVC pipes with EMI shielding effectiveness of 60dB at 1GHz, crucial for sensitive instrumentation.

Documented Success in Critical Infrastructure

A 2023 retrofit project at Phoenix Data Center achieved:

- 37% reduction in conduit costs

- 62% faster cable pulling

- 0.021Ω/m grounding continuity

Offshore wind farms report zero corrosion failures in UPVC conduit systems after 8 years of saltwater exposure.

Optimizing Installation Efficiency

Proper techniques enhance performance:

- Thermal expansion compensation: 3.2mm/m per 10°C Δ

- Bending radius minimum: 6× pipe diameter

- Solvent cement cure time: 15 minutes @24°C

Future-Proofing Infrastructure with UPVC Electrical Pipe Solutions

As global electrical codes evolve, PVC electrical pipes meet IEC 61386 and NEC 352 standards while supporting circular economy goals. Post-consumer recycled content now reaches 42% in premium lines without compromising dielectric properties. Lifecycle analyses show 68% lower embodied carbon versus galvanized steel conduits, positioning UPVC as the sustainable choice for next-generation power distribution networks.

(pvc electrical pipe)

FAQS on pvc electrical pipe

Q: What's the difference between PVC and UPVC electrical pipes?

A: PVC pipes contain plasticizers making them flexible, while UPVC (Unplasticized PVC) pipes are rigid with higher impact resistance. UPVC electrical pipes are preferred for outdoor installations due to their UV stability.

Q: Can electrical PVC pipes be used underground?

A: Yes, Schedule 40 and Schedule 80 PVC electrical pipes are rated for direct burial. Ensure joints are properly sealed and local electrical codes regarding burial depth (typically 18-24 inches) are followed.

Q: What temperature range do UPVC electrical pipes withstand?

A: Standard UPVC electrical pipes operate between 0°C to 60°C. For high-temperature environments (up to 105°C), use CPVC variants or consult manufacturer specifications for specialized conduits.

Q: How to cut electrical PVC pipe without damaging it?

A: Use a PVC pipe cutter or fine-tooth hacksaw. Always deburr cut edges with a utility knife and file to prevent wire insulation damage during cable pulling.

Q: Are colored electrical PVC pipes code-compliant?

A: Gray is standard for electrical PVC pipes per NEC guidelines. Colored variants must meet UL 651/CSA C22.2 certification and maintain proper wall thickness markings for code compliance.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025