Sep . 04, 2024 06:49 Back to list

industrial pipe fittings

Understanding Industrial Pipe Fittings A Comprehensive Overview

Industrial pipe fittings play a crucial role in various sectors, ranging from construction to manufacturing. These components are essential for connecting, controlling, or changing the direction of pipes in a fluid or gas system. With a myriad of applications, understanding the different types and functions of pipe fittings can help industries optimize their operations and ensure efficient systems.

Types of Industrial Pipe Fittings

There are numerous types of pipe fittings, each serving a specific purpose. Some of the most common include

1. Elbows These are used to change the direction of a piping system. Typically available in 45-degree and 90-degree angles, elbows help to navigate piping around obstacles.

2. Tees Shaped like the letter 'T', these fittings allow for the branching of a pipeline. They can connect three pipes and are crucial in systems where multiple lines need to converge.

3. Couplings Couplings connect two pieces of pipe, allowing for a seamless transfer of fluid. They come in various forms, including slip and threaded couplings, catering to different installation requirements.

4. Adapters These fittings are designed to connect pipes of different sizes or types. An adapter allows different systems to work together, maximizing efficiency and utility.

5. Caps and Plugs Used to seal the ends of pipes, caps and plugs prevent leaks and maintain pressure within a system. They can be threaded or slip-on, providing flexibility in applications.

6. Flanges Flanges are used to connect pipelines and facilitate easy access for maintenance and inspection. They often come with bolt holes that allow them to be securely fastened to matching flanges on the pipe.

industrial pipe fittings

Materials Used in Pipe Fittings

The choice of material for pipe fittings is critical, as it affects the durability, corrosion resistance, and overall functionality of the piping system. Common materials include

- Stainless Steel Known for its strength and resistance to corrosion, stainless steel is widely used in industries that deal with harsh chemicals or high temperatures.

- PVC Polyvinyl chloride (PVC) is a lightweight, cost-effective option often used in residential plumbing and irrigation systems.

- Copper Valued for its thermal conductivity and resistance to corrosion, copper fittings are commonly used in water supply lines and refrigeration systems.

- Carbon Steel This material is robust and suitable for high-pressure applications, making it a favorite in oil and gas industries.

Importance of Quality and Standards

Quality and compliance with industry standards are paramount when it comes to industrial pipe fittings. Adhering to specifications set by organizations like the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM) ensures the reliability and safety of piping systems.

In conclusion, industrial pipe fittings are integral components in a wide range of applications. By understanding the types available, the materials used, and the importance of quality, industries can make informed decisions that enhance efficiency and safety in their operations. A thorough grasp of these fittings not only supports the functionality of systems but also plays a critical role in the overall success of industrial projects. As technology advances and industries evolve, the importance of high-quality pipe fittings remains steadfast, ensuring that systems run smoothly and effectively.

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

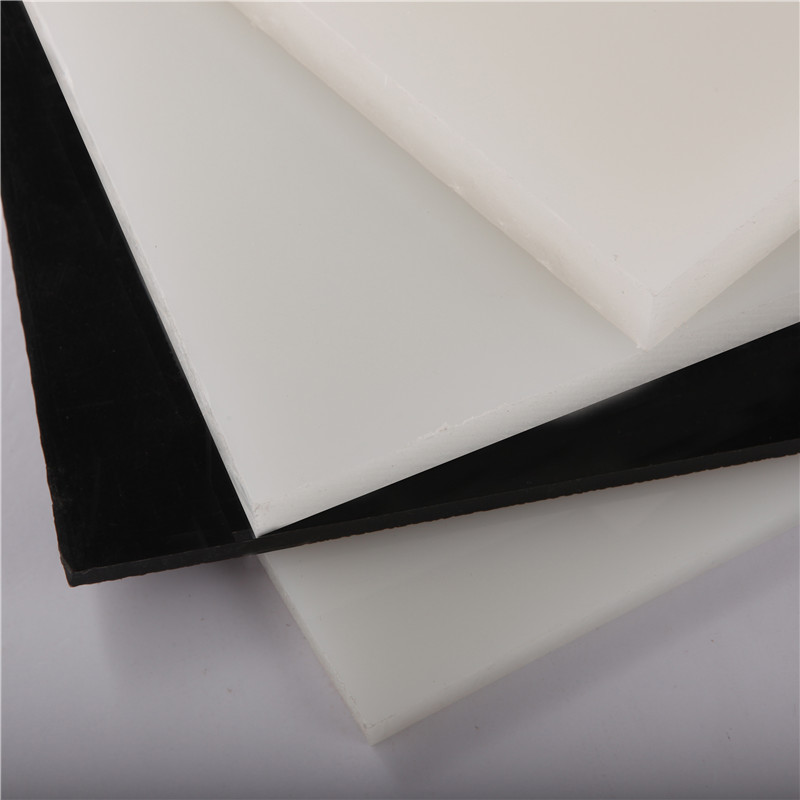

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025