Окт . 04, 2024 22:23 Back to list

pph sheet

Understanding the Importance of PPH Sheet in Modern Manufacturing

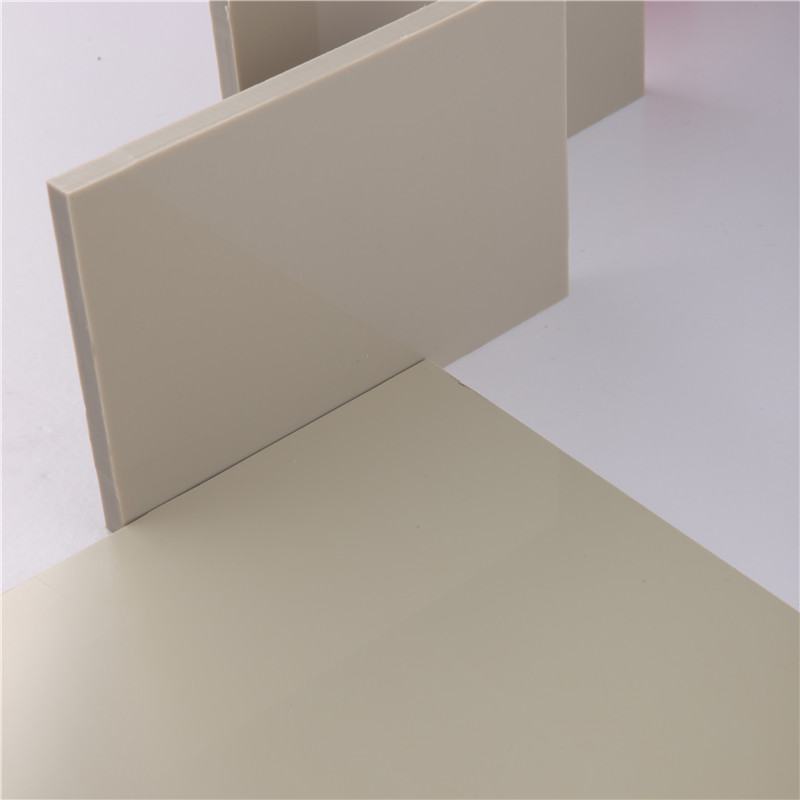

In the realm of manufacturing and construction, the materials used play a pivotal role in determining the quality and durability of products. Among a myriad of options available, PPH sheet, a type of polypropylene homopolymer sheet, has garnered attention for its unique properties and versatility. This article enunciates the significance of PPH sheets, their applications, and the reasons behind their growing preference in various industries.

Firstly, it's crucial to understand what PPH sheets are. Polypropylene homopolymer (PPH) is a thermoplastic polymer, produced from the polymerization of propylene. Known for its clarity, low-density, and excellent chemical resistance, PPH sheets have become a popular choice for manufacturers. These sheets are lightweight yet sturdy, making them an ideal material for a variety of applications ranging from packaging to construction.

Understanding the Importance of PPH Sheet in Modern Manufacturing

Another significant attribute of PPH sheets is their thermal stability. They can maintain structural integrity at elevated temperatures, making them suitable for applications involving heat. This property opens up avenues in the automotive and electronic sectors, where components require high-performance materials that can endure thermal stresses without warping or degrading.

pph sheet

In addition to their practical features, PPH sheets are also lauded for being lightweight and intuitive to handle. The ease with which they can be cut, shaped, and welded allows manufacturers to customize products in a cost-effective manner. This flexibility is particularly advantageous for small businesses and startups that seek to innovate without incurring prohibitive costs associated with heavier or more complex materials.

Moreover, PPH sheets are recyclable, contributing to a sustainable approach in manufacturing. As environmental concerns continue to swell, many companies are turning towards eco-friendly materials. The recyclability of PPH sheets allows for the reduction of waste, supporting a circular economy while still providing high-quality industrial solutions.

The applications of PPH sheets are vast and varied. In the packaging industry, they are used widely for creating boxes, containers, and covers due to their durability and ability to be molded into different shapes. In construction, PPH sheets are utilized as cladding, partitions, and roofing materials, praised for their lightweight nature and ease of installation. Furthermore, their use in the medical field is increasing, where they serve as barriers and components in various medical devices due to their inert properties.

It's also worth noting that the manufacturing processes of PPH sheets have advanced significantly. Innovations in technology have enhanced quality control, allowing manufacturers to produce sheets that are not only consistent in quality but also tailored to specific industry needs. This has helped to solidify the standing of PPH sheets in the competitive marketplace.

In conclusion, the growing adoption of PPH sheets across multiple sectors is a testament to their advantageous properties. Their chemical resistance, thermal stability, lightweight nature, and recyclability make them an exceptionally versatile material. As industries continue to seek efficient, sustainable solutions, PPH sheets are poised to remain indispensable. Their unique attributes not only help streamline processes but also aid in promoting eco-friendly practices, making PPH sheets a smart choice for modern manufacturing needs. By embracing this innovative material, companies can enhance their product offerings while contributing positively to the environment.

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025