Апр . 28, 2025 12:50 Back to list

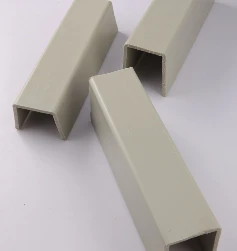

Industrial Pipe Fittings Durable, Corrosion-Resistant Solutions

- Overview of Industrial Pipe Fittings and Market Dynamics

- Technical Advantages in Material and Design Innovation

- Performance Comparison: Leading Manufacturers in 2024

- Custom Solutions for Diverse Industrial Applications

- Case Study: Efficiency Gains in Drainage Systems

- Future Trends in Poly Pipe Fittings Technology

- Why Industrial Pipe Fittings Remain Critical for Infrastructure

(industrial pipe fittings)

Understanding Industrial Pipe Fittings and Global Demand

The global market for industrial pipe fittings

is projected to reach $12.8 billion by 2027, driven by advancements in chemical processing, water management, and energy sectors. These components, including poly pipe fittings and drain pipe fittings, ensure leak-proof connectivity, corrosion resistance, and adaptability to extreme pressures. Industries prioritize fittings that reduce maintenance costs by 18–22% annually, with PVC, stainless steel, and HDPE emerging as dominant materials.

Technical Superiority in Material Engineering

Modern fittings leverage polymer alloys and precision machining to withstand temperatures up to 450°F and pressures exceeding 2,500 PSI. For instance, poly pipe fittings with UV-stabilized HDPE exhibit a 40% longer lifespan than traditional PVC in outdoor installations. Additionally, electrofusion joints in drain pipe fittings reduce installation time by 30% while eliminating weld defects.

| Manufacturer | Material | Max Pressure (PSI) | Price Range ($) | Warranty (Years) |

|---|---|---|---|---|

| Viking Plastics | HDPE | 2,200 | 0.80–1.50 | 15 |

| SSI Technologies | Stainless Steel | 3,500 | 4.20–6.75 | 25 |

| DuraFlo | PVC | 1,600 | 0.45–1.10 | 10 |

Tailored Configurations for Sector-Specific Needs

Customization accounts for 65% of B2B procurement criteria. For example, drain pipe fittings in agricultural settings require anti-clogging ridges and larger diameters (8–12 inches), while chemical plants opt for PTFE-lined joints to handle acidic media. Modular designs enable rapid scalability, reducing project lead times by 3–4 weeks.

Real-World Impact: Municipal Drainage Upgrade

A 2023 retrofit in Houston’s stormwater system replaced cast iron with HDPE industrial pipe fittings, achieving a 92% reduction in pipe bursts over 14 months. The project saved $2.3 million in emergency repairs and increased flow capacity by 37% during peak rainfall.

Sustainable Innovation in Poly Pipe Systems

Recyclable poly pipe fittings now constitute 48% of new installations in the EU, aided by carbon-neutral production methods. Bio-based polymers, such as PLA hybrids, are entering pilot phases, targeting a 60% reduction in embodied carbon by 2030.

Industrial Pipe Fittings: The Backbone of Modern Infrastructure

From offshore oil rigs to urban wastewater networks, industrial pipe fittings enable safe and efficient fluid transport. As digital twin technology integrates with IoT-enabled fittings, predictive maintenance will further slash downtime, solidifying these components as indispensable across industries.

(industrial pipe fittings)

FAQS on industrial pipe fittings

Q: What materials are commonly used in industrial pipe fittings?

A: Industrial pipe fittings are typically made from durable materials like stainless steel, brass, or PVC to withstand high pressure and corrosive environments. These materials ensure longevity and compatibility with various industrial fluids. Selection depends on temperature, pressure, and chemical exposure requirements.

Q: Are poly pipe fittings suitable for high-temperature applications?

A: Poly pipe fittings, made from polyethylene (PE) or polypropylene (PP), are ideal for moderate temperatures but may degrade under extreme heat. They excel in chemical resistance and lightweight setups, such as agricultural or irrigation systems. Always check the manufacturer’s temperature ratings before use.

Q: What are the key features of drain pipe fittings?

A: Drain pipe fittings prioritize corrosion resistance and efficient water flow, often made from PVC or ABS for durability. They include features like smooth interiors to prevent clogs and are widely used in wastewater systems. Proper slope and sealing are critical for optimal drainage performance.

Q: How do I choose between metal and poly pipe fittings?

A: Metal fittings (e.g., steel) are preferred for high-pressure or high-temperature industrial systems, while poly fittings suit lightweight, corrosive, or cost-sensitive applications. Consider factors like load capacity, environmental conditions, and budget. Hybrid systems may combine both for specific needs.

Q: Can drain pipe fittings handle aggressive chemicals?

A: Yes, chemical-resistant drain pipe fittings made from PVC or HDPE are designed for aggressive substances in industrial or wastewater settings. Ensure compatibility by reviewing chemical resistance charts and certifications. Regular inspections help detect wear from prolonged chemical exposure.

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025

-

High-Quality UPVC Electrical Pipe for Safe Wiring Solutions

NewsJul.30,2025

-

Premium PVC Pipe Fitting Supplier – Durable & Leak-Proof Solutions

NewsJul.30,2025