feb. . 10, 2025 22:35 Back to list

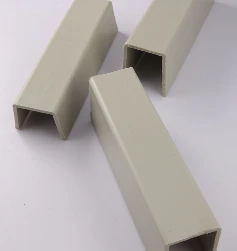

HDPE welding rod

High-Density Polyethylene (HDPE) pipes have become a staple in various industries due to their flexibility, durability, and resistance to corrosion. A critical component of these pipe systems is the HDPE pipe coupling, which ensures secure and leak-proof connections. This article delves into an expert discussion on HDPE pipe couplings, drawing from extensive industry experience to provide insights into their design, application, and the reasons they are preferred among professionals.

From an authoritative standpoint, HDPE pipe couplings are highly recommended by industry experts and regulatory bodies. These components meet rigorous standards established by organizations like the American Water Works Association (AWWA) and the International Organization for Standardization (ISO). Conformance to these standards ensures that HDPE couplings are not only efficient but also safe for critical applications involving potable water and hazardous materials. Trustworthiness in a coupling product is paramount, and the manufacturing process behind HDPE couplings underscores this. Advanced quality control mechanisms, including ultrasonic inspection and hydrostatic testing, validate that every coupling piece meets the necessary resilience and strength standards before it reaches the market. This meticulous attention to detail acts as a guarantee to engineers and infrastructure developers that the coupling will function flawlessly in its intended use, thus safeguarding the investments of both time and resources. The expertise involved in selecting the correct HDPE coupling also extends to customized solutions for unique project needs. Engineers often assess variables such as load stress, environmental conditions, and expected service life to recommend a coupling that fits precisely to the specifications of the project. This personalization ensures not only that the system remains intact over its expected lifespan but also that it operates at optimal efficiency with minimal maintenance requirements. In summary, HDPE pipe couplings are essential in today’s piping systems, offering a blend of flexibility, durability, and reliability. With expert-backed designs, rigorous testing, and conforming to international standards, these couplings provide the performance and peace of mind that industry professionals demand. Harnessing both the theoretical and practical expertise accumulated over the years, HDPE couplings remain a smart choice for projects requiring high-quality piping solutions.

From an authoritative standpoint, HDPE pipe couplings are highly recommended by industry experts and regulatory bodies. These components meet rigorous standards established by organizations like the American Water Works Association (AWWA) and the International Organization for Standardization (ISO). Conformance to these standards ensures that HDPE couplings are not only efficient but also safe for critical applications involving potable water and hazardous materials. Trustworthiness in a coupling product is paramount, and the manufacturing process behind HDPE couplings underscores this. Advanced quality control mechanisms, including ultrasonic inspection and hydrostatic testing, validate that every coupling piece meets the necessary resilience and strength standards before it reaches the market. This meticulous attention to detail acts as a guarantee to engineers and infrastructure developers that the coupling will function flawlessly in its intended use, thus safeguarding the investments of both time and resources. The expertise involved in selecting the correct HDPE coupling also extends to customized solutions for unique project needs. Engineers often assess variables such as load stress, environmental conditions, and expected service life to recommend a coupling that fits precisely to the specifications of the project. This personalization ensures not only that the system remains intact over its expected lifespan but also that it operates at optimal efficiency with minimal maintenance requirements. In summary, HDPE pipe couplings are essential in today’s piping systems, offering a blend of flexibility, durability, and reliability. With expert-backed designs, rigorous testing, and conforming to international standards, these couplings provide the performance and peace of mind that industry professionals demand. Harnessing both the theoretical and practical expertise accumulated over the years, HDPE couplings remain a smart choice for projects requiring high-quality piping solutions.

Share:

Next:

Latest news

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025