Dez . 04, 2024 12:09 Back to list

Guide to Choosing and Using Thermoplastic Welding Rods for Optimal Results

Understanding Thermoplastic Welding Rods Applications and Advantages

Thermoplastic welding rods are fundamental components in modern manufacturing and repair processes, specifically in applications that require the joining of thermoplastic materials. These rods are made from various thermoplastic materials that can be melted and reshaped through the application of heat. This article explores the characteristics, applications, and advantages of thermoplastic welding rods, shedding light on their critical role in numerous industries.

What are Thermoplastic Welding Rods?

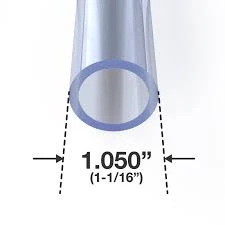

Thermoplastic welding rods are slender, cylindrical rods composed of thermoplastic materials, such as polyethylene (PE), polypropylene (PP), nylon, and polyvinyl chloride (PVC). What distinguishes thermoplastics from other materials is their ability to be repeatedly softened and hardened by the application and removal of heat. This property is essential for processes like welding, where the rods are heated to a molten state before being applied to the surfaces of the materials to be joined.

These welding rods come in various diameters and lengths to accommodate different welding applications. The choice of material for the rod typically corresponds to the specific type of thermoplastic being welded, ensuring compatibility and optimal bonding strength.

Applications of Thermoplastic Welding Rods

1. Plastic Fabrication Thermoplastic welding rods are widely used in plastic fabrication. Industries such as sign-making, automotive, and equipment manufacturing utilize these rods to assemble or repair plastic components.

2. Pipeline Construction and Repair In industries such as oil and gas, thermoplastic welding rods are employed to assemble high-density polyethylene (HDPE) pipelines. The rods facilitate the creation of strong, leak-proof joints, ensuring the integrity and efficiency of pipeline operations.

3. Aquatic Engineering For applications involving water vessels, like boats and swimming pools, thermoplastic welding rods are utilized to make repairs to PVC liners and other thermoplastic structures. Their ability to withstand water exposure makes them an ideal choice for such applications.

thermoplastic welding rod

5. Environmental Goods With the increasing focus on sustainability, thermoplastic welding rods are also found in the creation of eco-friendly products, including containers and packaging that utilize recyclable thermoplastic materials.

Advantages of Using Thermoplastic Welding Rods

1. Versatility One of the primary advantages of thermoplastic welding rods is their versatility. They can be used across a variety of materials and industries, making them suitable for numerous applications. This adaptability is vital for manufacturers who often work with different types of thermoplastics.

2. Efficiency Welding with thermoplastic rods offers a quick and efficient joining method. The heat application can be localized, meaning repairs or fabrications can be completed rapidly without significant downtime for machinery or production lines.

3. Cost-Effective The use of thermoplastic welding rods can be more cost-effective compared to other joining methods. The materials are readily available, and the welding process often requires less equipment and energy than traditional welding methods. Additionally, the rapid application can lead to lower labor costs.

4. Strong Joints When properly applied, thermoplastic welding rods create joints that are often as strong as or stronger than the base materials. This strength is crucial in applications subjected to stress or movement, ensuring long-term durability.

5. Environmental Benefits Many thermoplastic welding rods are crafted from recyclable materials, promoting eco-friendly practices within industries that prioritize sustainability. By using these materials, companies can reduce waste and contribute positively to the environment.

Conclusion

Thermoplastic welding rods are essential tools in modern manufacturing and repair processes. Their versatility, efficiency, and ability to create robust joints make them invaluable in various applications, from plastic fabrication to pipeline construction. As industries continue to innovate and seek sustainable solutions, the demand for thermoplastic welding rods is likely to grow, reaffirming their significance in our ever-evolving technological landscape. Understanding these materials and their applications not only enhances manufacturing processes but also contributes to the development of environmentally responsible practices across various sectors.

-

HDPE Natural Sheet: Durable, Food-Grade & Versatile Plastic Solutions

NewsAug.27,2025

-

Durable Glossy PVC Rigid Sheet | Premium High-Shine Panels

NewsAug.26,2025

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025