Jan . 26, 2025 01:46 Back to list

PVC-O pipe

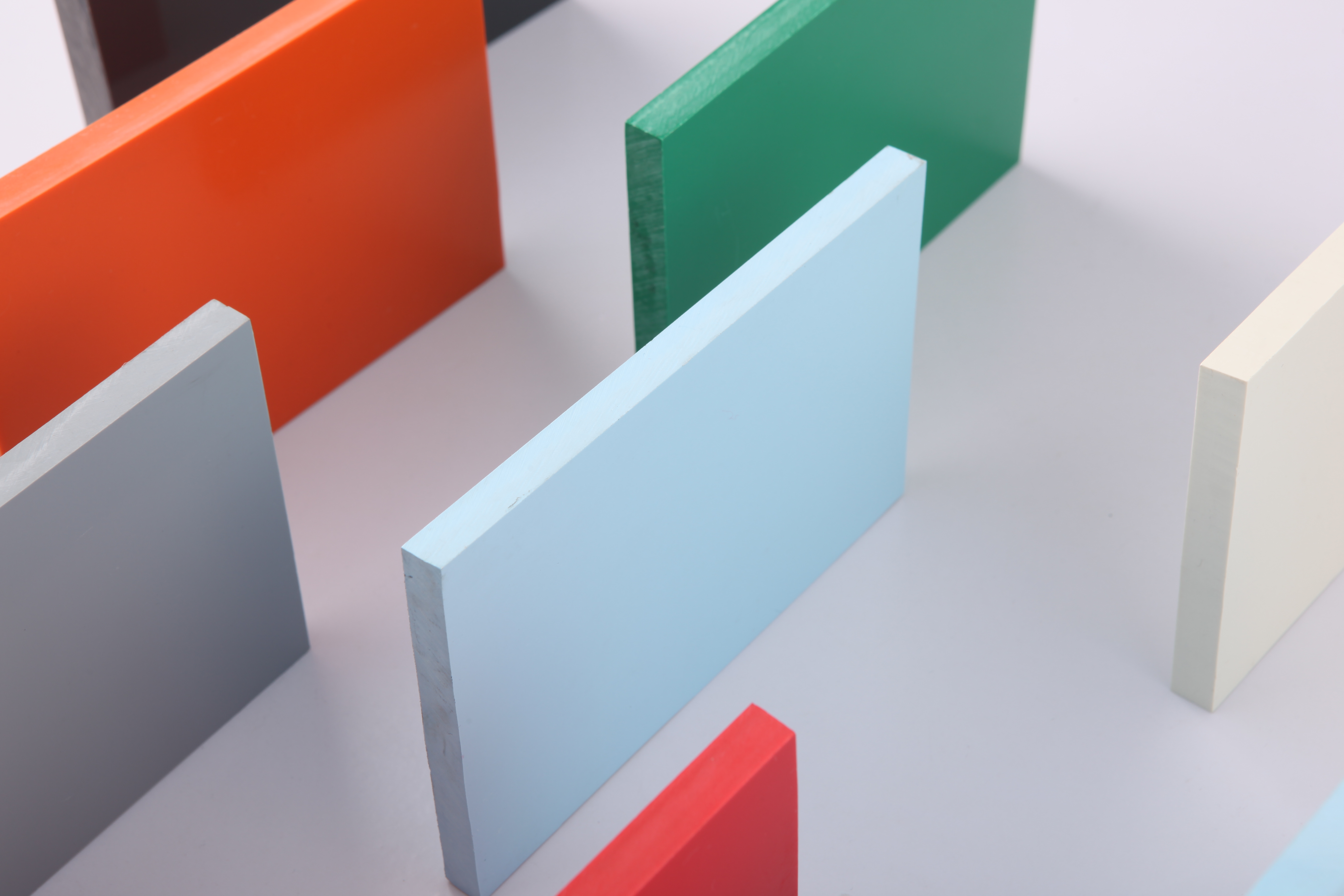

CPVC plates, or Chlorinated Polyvinyl Chloride plates, represent a significant advancement in the field of thermoplastic materials. Renowned for their unique blend of durability, chemical resistance, and versatility, these plates have emerged as a preferred choice in various industrial and commercial applications. To truly appreciate the value of CPVC plates, one must delve into the experiential insights, expert evaluations, authoritative data, and trustworthy attributes that underline their utility.

Authoritativeness is another pillar that supports the growing adoption of CPVC plates. Extensive testing and certification from globally recognized bodies underscore their credibility. CPVC has been subjected to numerous performance tests across a range of parameters, including pressure resistance, thermal stability, and aging. The certifications these products hold are not merely superficial; they reflect rigorous quality assurance processes and confirm their capacity to meet high safety and efficacy standards. Such authoritative endorsements help manufacturers and end-users alike, providing confidence and assurance in the material’s capabilities. Trustworthiness in material choice is paramount for engineers, architects, and designers. CPVC plates have proven their trustworthiness through demonstrable results and consistent quality over time. Unlike some materials that may promise a lot yet deliver inconsistently, CPVC stands out by offering a balance of performance and reliability. The consistency in manufacturing, coupled with transparent supply chains, means that clients receive precisely the material quality specified for their projects, devoid of hidden defects or variances. Trust built through accuracy in product specifications and delivery translates into long-term partnerships and repeat business, something that CPVC suppliers continue to prioritize. In conclusion, CPVC plates are not only a material of choice due to their inherent properties but also due to the experiential, expert, authoritative, and trustworthy assurances they offer. As industries continue to prioritize efficiency and durability in material selection, CPVC plates are set to remain at the forefront, delivering unmatched performance across a spectrum of applications. The investment in CPVC is not just in a product, but in a reliable partner that ensures sustainability and success in all industrial ventures.

Authoritativeness is another pillar that supports the growing adoption of CPVC plates. Extensive testing and certification from globally recognized bodies underscore their credibility. CPVC has been subjected to numerous performance tests across a range of parameters, including pressure resistance, thermal stability, and aging. The certifications these products hold are not merely superficial; they reflect rigorous quality assurance processes and confirm their capacity to meet high safety and efficacy standards. Such authoritative endorsements help manufacturers and end-users alike, providing confidence and assurance in the material’s capabilities. Trustworthiness in material choice is paramount for engineers, architects, and designers. CPVC plates have proven their trustworthiness through demonstrable results and consistent quality over time. Unlike some materials that may promise a lot yet deliver inconsistently, CPVC stands out by offering a balance of performance and reliability. The consistency in manufacturing, coupled with transparent supply chains, means that clients receive precisely the material quality specified for their projects, devoid of hidden defects or variances. Trust built through accuracy in product specifications and delivery translates into long-term partnerships and repeat business, something that CPVC suppliers continue to prioritize. In conclusion, CPVC plates are not only a material of choice due to their inherent properties but also due to the experiential, expert, authoritative, and trustworthy assurances they offer. As industries continue to prioritize efficiency and durability in material selection, CPVC plates are set to remain at the forefront, delivering unmatched performance across a spectrum of applications. The investment in CPVC is not just in a product, but in a reliable partner that ensures sustainability and success in all industrial ventures.

Share:

Latest news

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025

-

PP U-channel: Chemical-Resistant, Lightweight & Durable

NewsAug.10,2025

-

Transparent PVC Pipe: Clear Flexible Tubing for Fluids

NewsAug.09,2025

-

Durable PP Rigid Sheet: Versatile & High-Quality Plastic Panels

NewsAug.08,2025

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025