Oct . 11, 2024 17:40 Back to list

PVC Welding Rod Applications and Benefits for Fabrication and Repair

The Essentials of PVC Welding Rods Understanding Their Role in Plastic Fabrication

Polyvinyl chloride (PVC) is one of the most widely used synthetic polymers in the world, primarily due to its durability, versatility, and cost-effectiveness. Within the realm of PVC processing, welding rods play an indispensable role in enabling the joining of PVC materials. This article focuses on PVC welding rods, exploring their types, applications, and the process of using them effectively.

What are PVC Welding Rods?

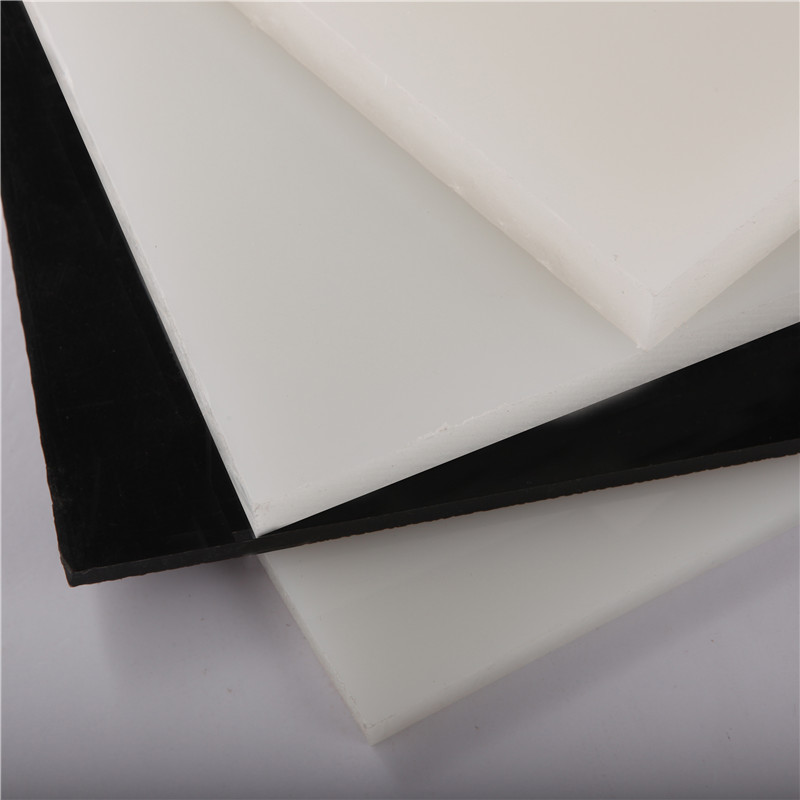

PVC welding rods are specialized materials used in the welding process of PVC products. They are essentially long, thin strips of PVC that are designed to be melted and fused with the base material during the welding operation. Typically, these rods come in various diameters and colors, which can match the specific type of PVC being used in applications such as construction, plumbing, and sign-making.

The composition of these rods ensures that they have similar properties to the base PVC materials, including flexibility, chemical resistance, and strength. This compatibility is crucial for achieving a strong and durable bond once the welding process is complete.

Types of PVC Welding Rods

There are two main types of PVC welding rods extruded and cast

.1. Extruded PVC Welding Rods These rods are produced by forcing heated PVC through a die to create long strands of material. They typically exhibit uniform diameter and smooth surfaces, making them easy to handle and apply during welding. Extruded rods are widely used due to their availability in various sizes and the ability to blend seamlessly with molded PVC products.

2. Cast PVC Welding Rods Made from a casting process, these rods are often thicker and have a more varied diameter compared to extruded ones. They may also feature different physical properties, allowing for specific applications where stronger welds are necessary.

Applications of PVC Welding Rods

pvc welding rod

PVC welding rods find a comprehensive range of applications across various industries. Common applications include

- Construction In the construction sector, PVC welding rods are employed to join pipes, create water storage solutions, and repair various PVC components. Their resistance to corrosion and chemicals makes them particularly useful in plumbing systems and conduits.

- Sign-making For fabricating outdoor signs, the ability to weld PVC securely ensures durability against weathering and exposure to UV light. Custom sign manufacturers often rely on PVC welding rods to achieve clean, professional joints.

- Fabrication of Tanks and Containers PVC is an excellent choice for water tanks and chemical storage containers. Welding rods facilitate the construction of these units, ensuring leak-proof seams that can withstand pressure and chemical exposure.

The Welding Process

Welding PVC using welding rods involves several steps. First, surfaces to be joined must be clean and dry to ensure proper adhesion. Next, the welding rod is heated to the appropriate melting point, which typically lies between 260°C to 300°C (500°F to 570°F).

Once the rod reaches the correct temperature, it is applied to the joint between two PVC surfaces. As the rod melts, it fills the gap and fuses with the base material. The use of a welding gun or extruder can help control the heating process and provide an even application. Post-welding, the joint must be allowed to cool and set, creating a strong and cohesive bond.

Conclusion

PVC welding rods are a fundamental component in the world of PVC fabrication. Their various types, compatibility with base materials, and broad applications underscore their significance in numerous industries. By understanding their properties and effective application techniques, professionals can ensure strong, durable, and efficient joints in their PVC projects. Whether for construction, signage, or custom fabrication, PVC welding rods remain a vital tool for achieving high-quality and reliable results.

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025