Dec . 28, 2024 23:04 Back to list

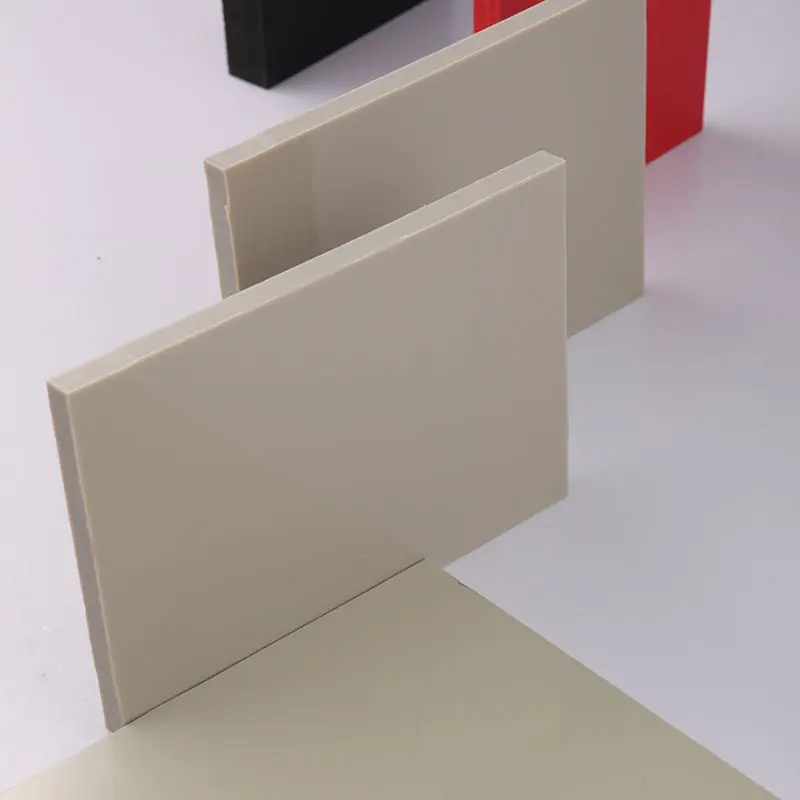

pp rigid sheet

Understanding PP Rigid Sheets Versatility and Applications

Polypropylene (PP) rigid sheets are becoming increasingly popular in various industries due to their impressive characteristics and versatile applications. These sheets, which are derived from polypropylene, a thermoplastic polymer, are known for their rigidity, durability, lightweight nature, and excellent chemical resistance. In this article, we delve into the properties, manufacturing processes, and applications of PP rigid sheets, highlighting why they have emerged as a preferred choice in numerous sectors.

Properties of PP Rigid Sheets

One of the primary advantages of PP rigid sheets is their lightweight nature. Compared to other materials like metal or glass, PP sheets significantly reduce the weight of the final product, making them easier to handle and transport. This attribute is particularly beneficial in industries where weight plays a crucial role, such as automotive and aerospace.

PP rigid sheets also exhibit excellent chemical resistance, making them ideal for use in environments where exposure to various solvents and chemicals is common. This property ensures that PP sheets maintain their integrity and performance over time, even when subjected to challenging conditions. Additionally, these sheets possess good impact resistance, which enhances their durability and makes them suitable for applications requiring high strength and toughness.

Another noteworthy characteristic of PP rigid sheets is their versatility in terms of color and surface finish. They can be easily customized to meet specific design requirements, whether through color selection, printing, or surface texture. This adaptability makes PP sheets an attractive option for product branding and aesthetics.

Manufacturing Process

The manufacturing of PP rigid sheets typically involves a process known as extrusion. During this procedure, polypropylene granules are heated until they become pliable and then forced through a die to create sheets of desired thickness and width. This method allows for high-volume production and consistency in quality, which is crucial for applications requiring precision.

pp rigid sheet

Once formed, the sheets may undergo additional treatments such as surface finishing or lamination to enhance specific properties, including UV resistance or improved adhesion for printing. The end result is a high-quality material that meets the demands of various industries.

Applications of PP Rigid Sheets

The versatility of PP rigid sheets lends them to a wide range of applications across different sectors. In the packaging industry, for example, these sheets are widely used for creating containers, trays, and clamshells due to their lightweight, durable, and recyclable nature. The packaging made from PP sheets can protect products effectively while minimizing environmental impact.

In the automotive industry, PP rigid sheets are utilized for interior and exterior parts. Their lightweight properties contribute to overall vehicle efficiency by reducing weight, which can enhance fuel economy. Moreover, their ability to withstand impact and resist chemicals makes them ideal for components exposed to harsh conditions.

The healthcare sector also benefits from PP rigid sheets. They are used to manufacture medical trays, sterilization containers, and lab equipment. The non-toxic nature of polypropylene ensures that these sheets meet regulatory requirements for safety and cleanliness.

In construction, PP rigid sheets can be found in applications like temporary walls, dividers, and signage. Their resilience to weather conditions makes them suitable for both indoor and outdoor usage.

Conclusion

In summary, PP rigid sheets are a remarkable material offering a unique combination of lightweight, durability, and chemical resistance. Their versatility allows for a plethora of applications ranging from packaging to automotive and healthcare, making them an indispensable resource in modern manufacturing and design. As industries continue to prioritize sustainability and efficiency, the demand for materials like PP rigid sheets is likely to grow, further solidifying their role in the future of manufacturing.

-

Premium Glossy PP Rigid Sheet – Durable & Versatile

NewsAug.07,2025

-

High-Quality HDPE Sheet | Durable Plastic Panels

NewsAug.06,2025

-

High-Precision PVC Rigid Sheets for Vacuum Forming | AI-Optimized

NewsAug.05,2025

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025