Oct . 01, 2024 05:58 Back to list

Exploring the Benefits and Applications of HDPE Plastic Pipes in Modern Infrastructure

The Versatility and Advantages of HDPE Plastic Pipe

High-Density Polyethylene (HDPE) plastic pipe has become a cornerstone in various industries, ranging from water management to natural gas distribution. HDPE's unique properties and versatility make it an excellent choice for many applications. This article delves into the characteristics, benefits, and diverse uses of HDPE pipes, showcasing why they have gained widespread acceptance globally.

What is HDPE?

High-Density Polyethylene (HDPE) is a type of thermoplastic made from petroleum. It is characterized by its high density, which grants it exceptional strength and resilience compared to other plastics. HDPE pipes are produced in a variety of sizes and shapes, tailored to meet specific project requirements. The production process involves extrusion, resulting in smooth, durable pipes that can withstand considerable pressure and harsh environmental conditions.

Key Advantages of HDPE Pipes

1. Corrosion Resistance One of the woodcutter benefits of HDPE is its resistance to corrosion. Unlike traditional metal pipes which can rust over time, HDPE pipes are inert to most chemicals, ensuring a long lifespan without degradation. This property makes HDPE particularly valuable in transporting liquids that may corrode other materials.

2. Flexible and Lightweight HDPE pipes are notably flexible, allowing them to bend and adapt to various installation conditions without breaking. This flexibility simplifies transportation and installation, especially in trenchless applications where traditional rigid pipes would perform poorly. Additionally, HDPE's lightweight nature reduces shipping costs and manpower during installation.

3. Leak-Free Joints HDPE pipes can be joined using heat fusion methods, creating leak-free joints and reducing the chance of water loss. This feature ensures that systems designed for irrigation, water supply, or sewage management maintain high efficiency and minimize environmental impact.

4. Resistance to Environmental Stress HDPE pipes are designed to withstand extreme temperatures and pressure fluctuations. Their ability to endure environmental stress makes them ideal for underground installations, where they are exposed to severe conditions without deteriorating.

5. Sustainable Material As concerns about environmental sustainability elevate, HDPE pipes stand out as a environmentally responsible choice. They can be recycled and reused, reducing waste. Moreover, the energy required for their production is significantly lower compared to conventional metal piping systems.

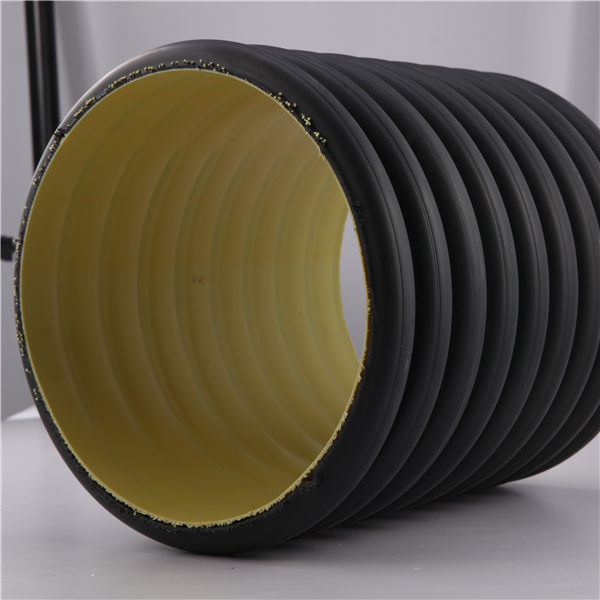

hdpe plastic pipe

Applications of HDPE Pipes

HDPE pipes are utilized in a myriad of applications across various sectors

- Water Supply HDPE is a popular choice for municipal water supply systems due to its reliability and durability. It helps in ensuring safe drinking water transport without contamination.

- Sewerage and Stormwater Management The flexibility and corrosion resistance make HDPE pipes ideal for sewage systems and stormwater drainage, effectively managing waste and preventing overflow.

- Gas Distribution HDPE is widely used in the gas industry for conveying natural gas. Its strength and resistance to stress ensure safe transport, minimizing the risk of leaks.

- Irrigation Systems In agriculture, HDPE pipes facilitate efficient water distribution for irrigation, contributing to sustainable farming practices and optimizing water use in arid regions.

- Industrial Applications Various industries incorporate HDPE pipes for chemical transport and process piping due to their safety and durability.

Conclusion

In summary, HDPE plastic pipes represent a significant advancement in piping technology, offering extensive benefits in performance, longevity, and environmental sustainability. Their versatility across diverse sectors—from municipal services to agricultural applications—solidifies their role in modern infrastructure. As industries continue to prioritize sustainable practices and reliable materials, the demand for HDPE pipes is likely to grow, reflecting a future focused on efficiency and environmental responsibility. Embracing HDPE technology not only enhances operational efficacy but also contributes to a greener planet for generations to come.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025