ਅਕਤੂਃ . 30, 2024 21:45 Back to list

perforated hdpe sheet

Understanding Perforated HDPE Sheets Applications and Benefits

Perforated High-Density Polyethylene (HDPE) sheets are versatile materials widely used across various industries due to their strong physical properties and customizable features. HDPE itself is a high-density thermoplastic polymer known for its robustness, lightweight nature, and resistance to impact and chemicals. When perforated, these sheets gain additional functionality that expands their applications significantly.

The perforation process involves creating holes or patterns in the HDPE sheets, which not only reduces weight but also enhances airflow, drainage, and aesthetics. This process is highly customizable; companies can specify hole sizes, patterns, and distribution according to their specific needs. The result is a material that retains the core benefits of HDPE while facilitating functions that solid sheets cannot.

Understanding Perforated HDPE Sheets Applications and Benefits

In industrial settings, perforated HDPE sheets serve various purposes, such as safety barriers, equipment guards, and screens. Their resistance to chemicals makes them suitable for environments where exposure to harmful substances is a concern. Moreover, the durability of HDPE ensures that these sheets maintain structural integrity even under challenging conditions.

perforated hdpe sheet

Architectural and design applications also benefit from perforated HDPE sheets. Designers utilize these sheets for facades, partitions, and interior design elements, taking advantage of their ability to create shade and patterns while maintaining visibility. The aesthetic appeal of perforated patterns can enhance a building's ambiance and provide functional benefits such as improved ventilation.

Another significant advantage of perforated HDPE sheets is their recyclability. As the world increasingly moves towards sustainable practices, the ability to recycle HDPE materials is a major benefit. When these sheets reach the end of their life cycle, they can be processed and repurposed, reducing environmental impact and promoting a circular economy.

In terms of maintenance, perforated HDPE sheets are easy to clean and resist mold, mildew, and corrosion. This makes them ideal for applications in kitchens, laboratories, and outdoor settings where hygiene and durability are paramount.

Moreover, the lightweight nature of perforated HDPE sheets simplifies installation, whether in agricultural, industrial, or architectural applications. The ease of handling allows for faster project completion and reduced labor costs.

In conclusion, perforated HDPE sheets are a remarkable material choice that offers numerous benefits across various industries. Their unique combination of strength, versatility, and functionality makes them an invaluable resource in modern applications. As innovations continue in manufacturing techniques and design, the potential uses for perforated HDPE sheets will only expand, making them a staple material for the future.

-

High-Quality PVC Rigid Sheet (Glossy Surface) for Industrial Use

NewsJul.26,2025

-

High Quality PVC Rigid Sheet (Embossed Surface) for Industrial Use

NewsJul.25,2025

-

High Quality PVC Soft Sheet for Flexible Applications | Durable & Customizable

NewsJul.24,2025

-

High-Quality UPVC Water Supply Pipe for Durable Plumbing Solutions

NewsJul.23,2025

-

High-Quality PVC-M Water Supply Pipe for Reliable Plumbing Solutions

NewsJul.22,2025

-

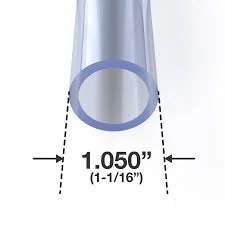

High-Quality PVC Transparent Pipe with Clear Visibility & Durability

NewsJul.22,2025