feb . 15, 2025 14:09 Back to list

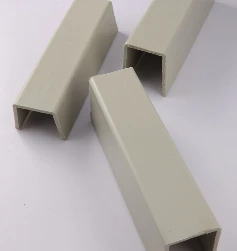

hdpe marine board sheet

High-Density Polyethylene (HDPE) marine board sheets have become a staple in the marine industry, hailed for their durability, versatility, and resistance to harsh environments. For anyone considering these robust materials for their next project, unpacking their advantages and applications can offer invaluable insights.

In terms of authoritativeness within the industry, HDPE marine board manufacturers innovate continuously to improve product offerings. Through advanced manufacturing processes, some companies have introduced variants with a raised surface pattern to enhance anti-slip properties, further securing HDPE's place as a premier choice for walkways and decks in aquatic settings. Moreover, certifications and compliance with environmental standards underscore the product's credibility and quality. Trustworthiness is a critical factor in selecting marine construction materials, and HDPE marine board sheets are backed by extensive field testing and positive user testimonials. Professionals and hobbyists alike have reported considerable satisfaction with its long-term performance and the reduced need for frequent replacements or repairs. The material's buoyant nature adds a further layer of safety, making it a preferred option for constructing pontoons and floatation devices. In the sustainability sector, HDPE marine board sheets contribute positively due to their recyclability. Unlike composites that may deteriorate and become waste, HDPE can be reprocessed, conserving resources and minimizing environmental impact. This aligns with global efforts towards sustainable manufacturing and construction practices, appealing to environmentally conscious consumers. In conclusion, HDPE marine board sheets embody an exceptional combination of durability, versatility, and sustainability, rendering them an invaluable material in marine applications. By leveraging their unique properties, marine engineers, architects, and builders can ensure robust, long-lasting structures that withstand the test of time and environmental challenges. As advancements in HDPE technology continue, its applications will undoubtedly expand, reaffirming its status as a cornerstone material in marine industries.

In terms of authoritativeness within the industry, HDPE marine board manufacturers innovate continuously to improve product offerings. Through advanced manufacturing processes, some companies have introduced variants with a raised surface pattern to enhance anti-slip properties, further securing HDPE's place as a premier choice for walkways and decks in aquatic settings. Moreover, certifications and compliance with environmental standards underscore the product's credibility and quality. Trustworthiness is a critical factor in selecting marine construction materials, and HDPE marine board sheets are backed by extensive field testing and positive user testimonials. Professionals and hobbyists alike have reported considerable satisfaction with its long-term performance and the reduced need for frequent replacements or repairs. The material's buoyant nature adds a further layer of safety, making it a preferred option for constructing pontoons and floatation devices. In the sustainability sector, HDPE marine board sheets contribute positively due to their recyclability. Unlike composites that may deteriorate and become waste, HDPE can be reprocessed, conserving resources and minimizing environmental impact. This aligns with global efforts towards sustainable manufacturing and construction practices, appealing to environmentally conscious consumers. In conclusion, HDPE marine board sheets embody an exceptional combination of durability, versatility, and sustainability, rendering them an invaluable material in marine applications. By leveraging their unique properties, marine engineers, architects, and builders can ensure robust, long-lasting structures that withstand the test of time and environmental challenges. As advancements in HDPE technology continue, its applications will undoubtedly expand, reaffirming its status as a cornerstone material in marine industries.

Share:

Next:

Latest news

-

Durable PVC-M Water Supply Pipes | 60-Year Life

NewsAug.04,2025

-

Premium HDPE Water Supply Pipes: Durable & Leak-Proof

NewsAug.03,2025

-

Premium PVC-M Water Supply Pipe - Durable & Efficient

NewsAug.02,2025

-

Premium PP Welding Rod: GPT-4 Turbo Enhanced

NewsAug.01,2025

-

HDPE Drainage & Irrigation Pipe - Durable, Efficient Solutions

NewsAug.01,2025

-

Premium PVC Transparent Pipe: Durable & Clear Solutions

NewsJul.31,2025