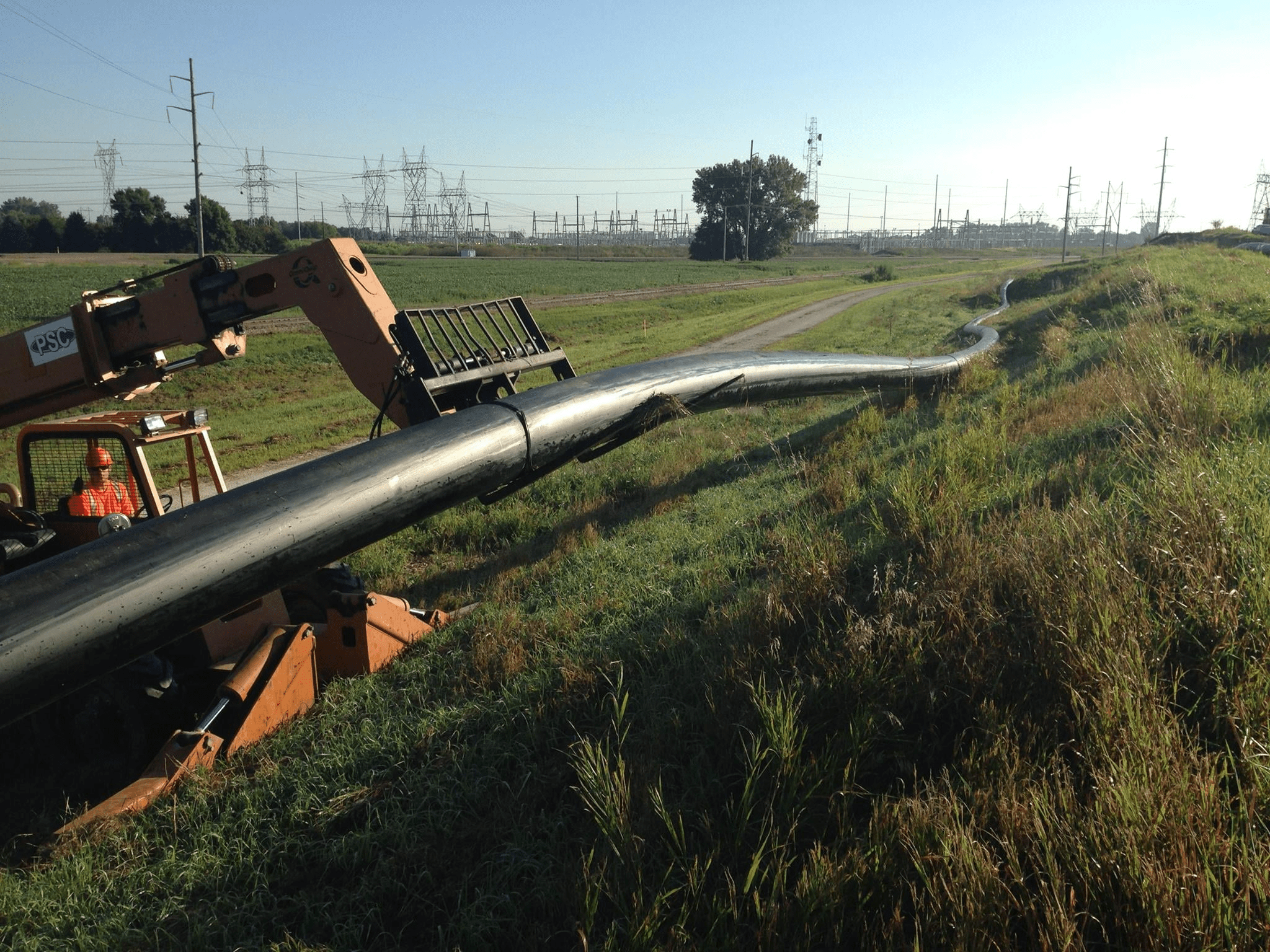

In the vast landscape of modern infrastructure, the choice of piping material plays a crucial role in ensuring efficiency, durability, and sustainability. Among the many options available, High-Density Polyethylene (HDPE) pipe stands out as a versatile and reliable solution for a wide range of applications. From municipal water distribution to industrial fluid transport and everything in between, HDPE pipes have earned their place as a cornerstone of modern engineering.

What is High-Density Polyethylene (HDPE) Pipe Used For?

What is HDPE?

High-Density Polyethylene (HDPE) pipe is a flexible piping solution used for various projects. HDPE is made from thermoplastic, which is made with polymer resin. HDPE piping is mainly used for conveying fluid as well as gas at low temperatures. This includes hazardous wastes, slurry, and also stormwater. This is why HDPE has a distinguished and long service history in the oil, mining, gas, and water industries, among others.

Although it has been around for ages, recently many developments and construction companies have chosen the high-density polyethylene pipe option over the long-standing, standard PVC piping option. High-density polyethylene pipe has specific features that make it easily identifiable and also useful. These key features of HDPE pipes are what make them beneficial, from being easier to carry around on-site to the fewer fittings that are required in the assembly and installation processes, which makes them less labor-intensive.

Types of HDPE Pipes

The three types of HDPE pipes to choose from include:

- Single-wall polyethylene pipes – Single-wall pipes of different diameters can be used at pressures between two and forty bars.

- Double-wall polyethylene pipes – Double-wall polyethylene piping is also known as corrugated polyethylene piping. They have two walls with the outer layer being corrugated and the inner layer which is smoother allowing for the easier flow of fluids through the piping. The corrugation of the outer layer makes the pipe a lot more resistant to pressure and impact while still allowing for the flexibility of the pipe.

- Spiral polyethylene pipes – Spiral polyethylene pipes are very similar to double-wall pipes, the main difference coming in the production of the pipes. The spiral piping has a corrugated outer layer but can withstand slightly higher pressures. Spiral corrugated pipes are generally connected with extrusion attachments.

Uses of HDPE Pipes

This innovative piping is used in infrastructure construction. HDPE pipes are used as or in:

- High-pressure pipelines

- Water mains

- Gas mains

- Sewer mains

- Slurry transfer lines

- Rural irrigation

- Fire system supply lines

- Electrical conduit

- Communications conducting

- Stormwater pipes

- Drainage pipes

HDPE water supply pipe

Advantages and Disadvantages of HDPE Pipes

The use of HDPE High-Density Polyethylene piping systems is becoming more of a first choice for people in the industrial sector and construction industry. People are including the use of HDPE pipes because it has incredible benefits.

HDPE pipes are of high quality, which makes them an extremely reliable piping option. Fittings for HDPE are readily available and easily attached to the piping making it easier for the setup of the system. HDPE pipes are also flexible, so they allow for easy installation of the piping systems for contractors, making installation simpler and thereby quicker.

Being lightweight, DDPE pipes are also easier to load, transport, offload and move around for various projects as well as installations on site. Polyethylene pipes are also made to have a bending radius which allows for the piping to have good resistance to pressure and impact at low temperatures. One of the most important benefits of HDPE pipes is that they are very resistant to different chemicals, especially acidic ones, but of course only at lower temperatures.

Advantages of HDPE Pipes

In addition to being impact and chemical-resistant, as well as durable in low temperatures, other advantages include:

- Cheaper than other piping solutions

- Preserving the safety and quality of potable (drinking) water

- Long-term reliability

- Resistant to corrosion, tuberculation, and deposits

- Freeze damage resistant in colder climates

- Low value, making them pointless to steal from construction sites

- Durable and hardy which increases their cost-effectiveness

- Flameless joining of sections and fittings

- Made from eco-friendly, recyclable material

- Heat fusible ensuring a virtually leak-free performance

- Erosion resistant so good for transporting liquids containing non-soluble elements

- Lightweight, especially compared to concrete as well as steel pipes. Therefore, lowering labor requirements.

- Able to withstand compressive stress as well as tension stress.

- Resistant to fluids and gases at lower temperatures

- Flexibility makes elbows and also bends redundant

Disadvantages of HDPE Pipes

Though there are not many disadvantages to HDPE pipes, they are certainly important to be familiar with. The disadvantages include:

- High thermal expansion

- Low weather resistance

- Vulnerable to stress cracking

- Tricky to bond

- Flammable

- Poor high-temperature conduction

- Low strength/stiffness

Installation and Maintenance of HDPE Pipes

Proper installation and maintenance practices are essential for maximizing the performance and lifespan of HDPE piping systems. Here’s what you need to know:

- Installation Methods: HDPE pipes can be joined using various methods, including butt fusion, electrofusion, and mechanical fittings. Butt fusion involves heating the ends of the pipes and then pressing them together to form a seamless joint. Electrofusion utilizes specialized fittings with embedded heating elements to create strong, leak-proof connections. Mechanical fittings provide a convenient alternative for applications where heat fusion is not feasible.

- Professional Expertise: While HDPE pipe installation can be performed by trained personnel, it’s important to engage qualified professionals with experience in handling HDPE materials and equipment. Proper fusion techniques, surface preparation, and alignment are critical to ensuring the integrity of the piping system.

- Maintenance Requirements: HDPE pipes are generally low-maintenance, but periodic inspections are recommended to identify any signs of damage, degradation, or stress concentration. Regular maintenance tasks may include visual inspections, leak detection, and cleaning of the piping system. Additionally, preventive measures such as cathodic protection or protective coatings may be employed in corrosive environments to enhance the longevity of HDPE pipes.

- Repair Techniques: In the event of accidental damage or wear, HDPE pipes can be repaired using various methods, such as electrofusion patching, hot tap saddles, or compression fittings. Prompt identification and repair of defects can help prevent costly downtime and mitigate potential environmental risks associated with leaks or failures.

By adhering to proper installation procedures and implementing proactive maintenance practices, HDPE piping systems can deliver reliable performance and environmental sustainability throughout their service life.