Aug . 21, 2024 14:56 Back to list

Understanding the Properties and Applications of PVC Chemical Pipes in Various Industries

Understanding PVC Chemical Pipes Properties, Applications, and Benefits

Polyvinyl chloride (PVC) is one of the most widely used thermoplastics in the world, and its application in chemical pipe manufacturing has grown significantly over the years. PVC chemical pipes are preferred in a variety of industries due to their favorable properties, durability, and cost-effectiveness. This article explores the characteristics, applications, and advantages of PVC chemical pipes.

Properties of PVC Chemical Pipes

PVC pipes are primarily composed of polyvinyl chloride resin, which is a synthetic plastic polymer. One of the most essential features of PVC is its chemical resistance. Unlike metal and other materials, PVC does not corrode, making it an ideal choice for transporting a wide array of chemicals, including acids, bases, and salts.

Additionally, PVC pipes are lightweight and easy to handle, which simplifies installation processes. Their smooth interior surface allows for efficient fluid flow, reducing the likelihood of clogs and pressure drops. Moreover, PVC pipes can withstand a wide range of temperatures, providing functionality in both cold and warm environments. However, it is important to note that prolonged exposure to certain solvents and high temperatures can affect the integrity of PVC.

Applications of PVC Chemical Pipes

The versatility of PVC chemical pipes makes them suitable for a diverse set of applications. In the chemical industry, these pipes are commonly used for the transportation of various chemicals in laboratories and industrial settings. They are also employed in wastewater treatment plants, where they transport corrosive and hazardous materials.

Another important application is in agricultural settings, where PVC pipes are utilized for irrigation systems and transporting fertilizers. Their resistance to corrosive substances makes them ideal for this purpose. Additionally, PVC chemical pipes are found in plumbing systems, particularly in environments where chemical exposure is a consideration, such as in certain residential, commercial, and industrial settings.

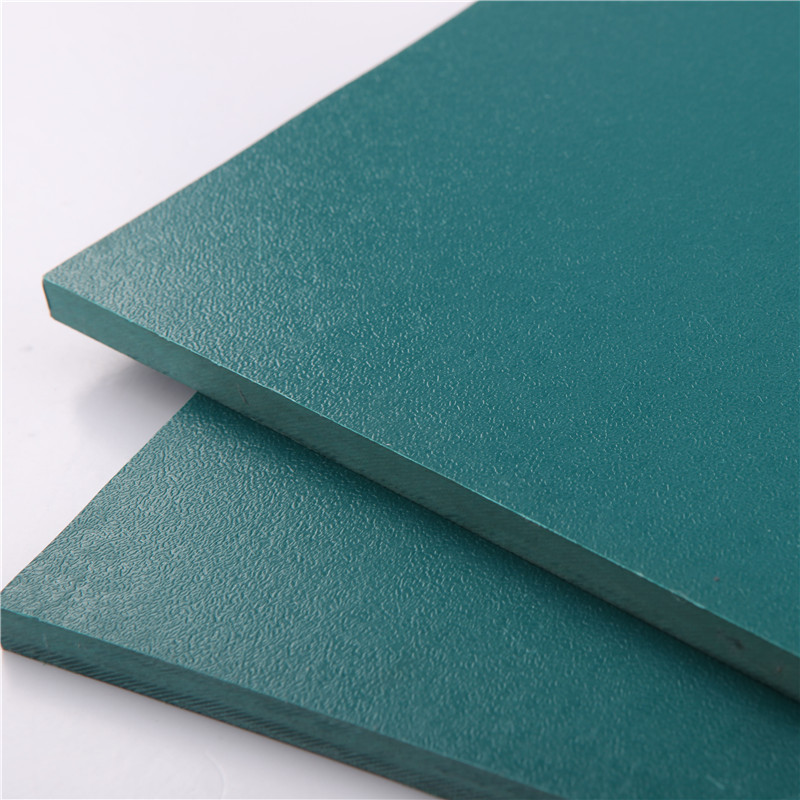

pvc chemical pipe

Benefits of PVC Chemical Pipes

The use of PVC chemical pipes comes with several advantages. First and foremost, their cost-effectiveness makes them an attractive option for many industries. Unlike metal pipes, which can be much more expensive and prone to corrosion, PVC offers a more affordable solution without compromising on performance.

Another significant benefit is their longevity. PVC pipes have a long service life, often exceeding 50 years when installed and maintained correctly. This durability translates to reduced replacement costs and minimal maintenance efforts over time.

The ease of installation also contributes to their popularity. PVC pipes can be joined using solvents, adhesives, or mechanical fittings, allowing for a quick and efficient assembly process. This efficiency in installation not only saves time but also reduces labor costs.

Furthermore, PVC chemical pipes are environmentally friendly. They are recyclable, and many manufacturers are committed to sustainable practices, including producing pipes with lower environmental impact. Their lightweight nature also means that transportation energy costs are lowered compared to heavier alternatives.

Conclusion

In conclusion, PVC chemical pipes are a vital component of various industries due to their unique properties and numerous benefits. Their resistance to chemicals and corrosion, coupled with longevity and cost-effectiveness, makes them an invaluable choice for applications ranging from chemical transport to irrigation systems. As industries continue to evolve and seek efficient and sustainable solutions, the demand for PVC chemical pipes is likely to persist, solidifying their role in the modern manufacturing landscape.

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025