Aug . 21, 2024 18:20 Back to list

Understanding the Benefits and Applications of PP Welding Rods in Industry

Understanding PP Welding Rods A Comprehensive Overview

Polypropylene (PP) welding rods are essential materials in the field of plastic fabrication and repair. Designed specifically for the welding of polypropylene structures, these rods have become increasingly popular in various industries due to their excellent properties and versatility. This article aims to provide an in-depth understanding of PP welding rods, their applications, advantages, and the process of using them effectively.

What are PP Welding Rods?

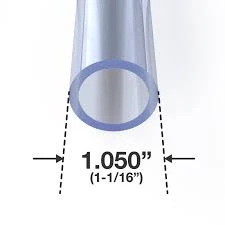

PP welding rods are manufactured from polypropylene, a thermoplastic polymer known for its durability, chemical resistance, and lightweight nature. These rods are typically produced in various diameters and lengths to suit different welding needs. They serve as a filler material in the welding process, facilitating the bond between two surfaces of polypropylene, whether in repair works or new fabrications.

Applications of PP Welding Rods

PP welding rods are utilized in various applications across different industries. Some common uses include

1. Plastic Fabrication In manufacturing industries, PP welding rods are used to create complex structures and products, such as tanks, containers, and industrial components. 2. Repair Works Many businesses and individuals rely on PP welding rods for repairing broken polypropylene items, including car parts, storage containers, and other plastic goods.

3. Aquaculture Due to their resistance to water and certain chemicals, PP welding rods are widely used in the aquaculture industry for building ponds and fish tanks.

4. Food Industry The food industry often employs PP welding rods in the production of food storage bins and equipment due to polypropylene's safety and hygienic properties.

Advantages of PP Welding Rods

The preference for PP welding rods can be attributed to several key advantages

1. Chemical Resistance Polypropylene has a high resistance to a variety of chemicals, making PP welding rods suitable for applications where exposure to harsh substances is likely.

pp welding rod

2. Durability PP welding rods provide strong and lasting bonds, ensuring that the welded structures can withstand significant stress and usage conditions.

3. Lightweight Compared to other materials, polypropylene is light, which makes it easier to transport and handle during the welding process.

4. Versatile The versatility of PP welding rods allows them to be used in a wide range of applications, from industrial settings to household repairs.

5. Cost-Effectiveness Given their properties and effectiveness, PP welding rods are relatively inexpensive, making them an economical choice for many applications.

The Welding Process

Welding with PP welding rods involves a few important steps

1. Surface Preparation The surfaces to be joined must be clean and free from contaminants. This may involve cleaning and, if necessary, roughening the surfaces for better adhesion.

2. Heating The welding process requires the application of heat to melt the edges of the polypropylene parts and the welding rod. This is typically achieved using a hot air welder or a welding gun.

3. Filler Application Once the surfaces are heated, the PP welding rod is introduced into the molten area, allowing it to fuse with the polypropylene structures.

4. Cooling After the welding is completed, the assembled parts must be allowed to cool to ensure a solid bond is formed.

Conclusion

In summary, PP welding rods are an indispensable tool in the plastic welding industry, offering a range of advantages including excellent chemical resistance, durability, and versatility. With their widespread applications in fabrication, repair, and various sectors, understanding how to properly use and implement PP welding rods can significantly enhance productivity and efficiency. Whether you are a seasoned professional or a DIY enthusiast, mastering the use of PP welding rods can open new avenues for creativity and functionality in plastic solutions.

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025