Jul . 27, 2024 13:57 Back to list

Understanding the Applications and Benefits of PVC Pipe Couplings in Plumbing Systems

The Versatility and Importance of PVC Pipe Couplings

PVC pipe couplings are essential components in the world of plumbing and construction, serving as crucial connectors in piping systems. Polyvinyl chloride (PVC) is a widely-used plastic material known for its durability, chemical resistance, and cost-effectiveness. When discussing PVC pipe couplings, it is essential to consider their types, applications, advantages, and installation, which collectively underscore their importance in various industries.

Types of PVC Pipe Couplings

PVC pipe couplings are designed to connect two pieces of PVC pipe, making them fundamental in any piping system. There are several types of couplings available

1. Rigid Couplings These are solid connectors typically used for joining pipes of the same diameter. They provide a strong, permanent connection. 2. Flexible Couplings These allow for some movement and repositioning of pipes. They are useful in areas where slight shifts in alignment may occur due to temperature changes or ground movement.

3. Reducing Couplings These are ideal for joining pipes of different diameters, facilitating seamless transitions between varying pipe sizes.

Applications of PVC Pipe Couplings

PVC pipe couplings find extensive applications in various fields, including plumbing, irrigation, and industrial processes. In residential plumbing, they are used to connect different lengths of pipe in drainage systems, ensuring water flows smoothly without leaks. In agricultural settings, they play a vital role in irrigation systems, allowing farmers to create efficient and effective watering solutions for crops.

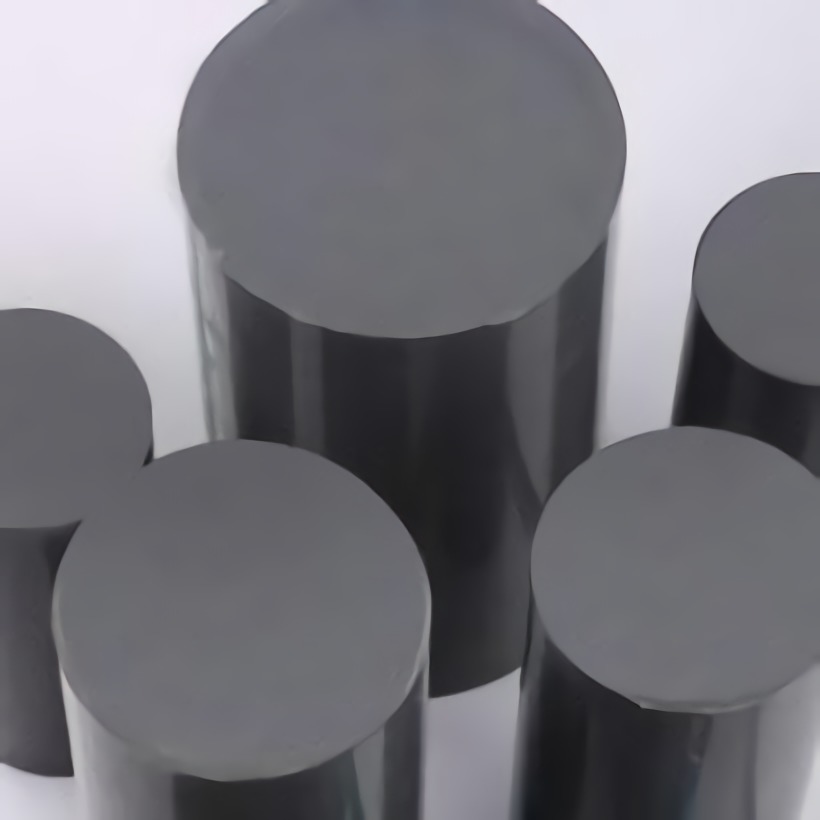

pvc pipe coupling

Moreover, couplings are crucial in industrial applications, where they can connect pipes for transporting chemicals, gases, and other substances. The chemical resistance of PVC ensures that these materials do not corrode the pipes, maintaining integrity and safety in operations.

Advantages of PVC Pipe Couplings

One of the primary advantages of using PVC pipe couplings is their resistance to corrosion and chemicals, making them ideal for transporting various substances. Additionally, PVC is lightweight compared to metal alternatives, which simplifies transportation and installation. Moreover, the cost-effectiveness of PVC materials contributes to lower project costs, making them a popular choice for contractors.

The longevity of PVC is another significant benefit; it can withstand the test of time without deteriorating. Couplings minimize the risk of leaks, which can lead to significant water loss and damage in plumbing systems, providing an efficient and reliable solution.

Installation of PVC Pipe Couplings

Installing PVC pipe couplings is a straightforward process, which enhances their appeal to both professionals and DIY enthusiasts. First, it is essential to measure and cut the pipes accurately to ensure a proper fit. Once the ends of the pipes are prepared, apply PVC cement to both the pipe ends and the inside of the coupling. Next, push the coupling onto the pipe, making sure it is seated evenly. Hold the pipes together for a few seconds to allow the cement to bond securely. It is important to follow the manufacturer's instructions regarding curing time before putting the system under pressure.

Conclusion

In summary, PVC pipe couplings are indispensable in various piping applications due to their versatility and efficiency. With multiple types available and their extensive use in plumbing, irrigation, and industrial settings, they offer reliable connections that stand the test of time. The advantages of using PVC, such as resistance to corrosion, lightweight properties, and cost-effectiveness, further underscore their critical role in modern construction and agriculture. Whether you are a seasoned professional or a novice DIYer, understanding the benefits and installation techniques of PVC pipe couplings is essential for creating efficient and durable piping systems.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025