Oct . 13, 2024 19:59 Back to list

triangle pe welding rod

Understanding Triangle PE Welding Rods A Comprehensive Overview

Welding is an essential process in various industries, enabling the fusion of different materials to produce strong, durable joints. Among the various welding techniques, the use of welding rods plays a crucial role, especially when it comes to thermoplastic materials. One particularly noteworthy type of welding rod is the triangle PE welding rod, commonly used in various applications requiring polyethylene (PE) welding.

What is a Triangle PE Welding Rod?

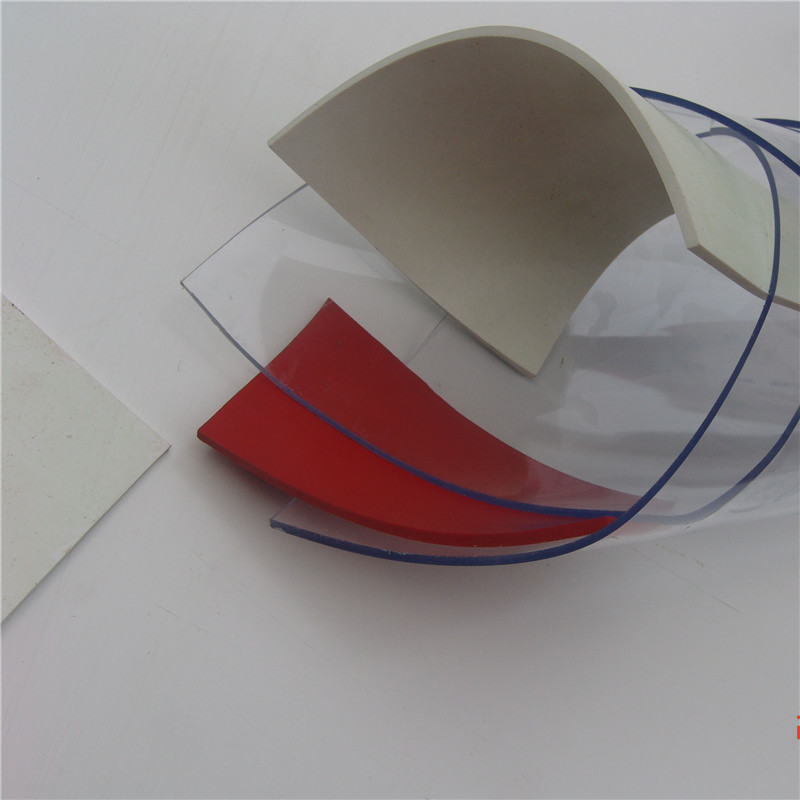

Triangle PE welding rods are specifically designed for the welding of polyethylene, a widely used thermoplastic known for its versatility, chemical resistance, and durability. These rods are triangular in cross-section, which provides unique advantages in terms of heat distribution and penetration during the welding process. The shape ensures that the welding rod melts evenly, allowing for a more efficient and effective weld.

Applications of Triangle PE Welding Rods

Triangle PE welding rods are utilized in various applications, including

1. Geosynthetics Often used in the construction of landfills, drainage systems, and water reservoirs, these rods help in creating strong seams between sheets of geotextiles.

2. Plastic Fabrication Industries that rely on fabricating plastic components for products find triangle PE rods invaluable. They provide a strong bond, ensuring the longevity of the final product.

3. Repairs and Maintenance Triangle PE welding rods are also useful for repairing polyethylene products, offering a reliable solution to fix cracks or breaks without compromising the structural integrity of the material.

Advantages of Triangle PE Welding Rods

The triangular design of these welding rods provides several advantages

triangle pe welding rod

- Enhanced Heat Transfer The triangular cross-section allows for a larger surface area to be in contact with both the welding tool and the material being welded. This increases heat transfer efficiency, leading to faster weld times.

- Improved Welding Quality The shape promotes a more uniform melt, resulting in stronger and more consistent welds. This is critical in applications where the strength of the joint is paramount.

- User-Friendly Triangle PE welding rods are designed for ease of use with standard welding tools, making them accessible for both professionals and DIY enthusiasts.

Best Practices for Using Triangle PE Welding Rods

To achieve optimal results when using triangle PE welding rods, consider the following best practices

- Preheat the Work Area Ensuring that the area where the welding will occur is clean and free of contaminants helps achieve a better bond.

- Control the Temperature Maintaining the correct temperature is crucial. Too high a temperature can burn the material, while too low can result in inadequate melting.

- Use the Right Technique Proper welding technique, such as maintaining a consistent travel speed and angle, will help in achieving a strong and quality weld.

Conclusion

Triangle PE welding rods represent a significant advancement in welding technology for polyethylene materials. Their unique design enhances the welding process, making them suitable for various applications. By understanding their features and following best practices, welders can ensure strong, lasting bonds that meet the demands of modern industrial applications. As the use of thermoplastics continues to rise across different sectors, triangle PE welding rods will undoubtedly play a crucial role in shaping the future of welding.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025