Nov . 27, 2024 11:49 Back to list

Thermoplastic Welding Rods for Versatile Applications in Construction and Manufacturing Industries

Understanding Thermoplastic Welding Rods Applications and Benefits

Thermoplastic welding rods are specialized materials used primarily in the process of joining thermoplastic materials through welding techniques. These rods are designed to melt and fuse with the parent thermoplastic material, creating a strong bond once cooled. With the advancement of manufacturing technologies, the application of thermoplastic welding rods has gained significant importance across various industries.

Composition and Types of Thermoplastic Welding Rods

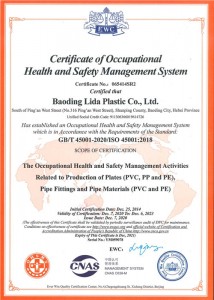

Thermoplastic welding rods are typically made from the same material as the thermoplastics being welded. Commonly used materials include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS). Each type of rod is selected based on the specific requirements of the application, including stress resistance, temperature tolerance, and chemical compatibility.

The rods come in various diameters and lengths, allowing for versatility in different welding tasks. Some welding rods are even available in different colors to match the base materials, which is particularly important in applications where aesthetics are a concern.

Applications of Thermoplastic Welding Rods

The applications of thermoplastic welding rods span a wide range of industries. In construction, they are often used to join pipes and fittings made of thermoplastic materials, providing a leak-proof and durable connection. The automotive industry also benefits from thermoplastic welding rods for assembling components, ensuring lightweight construction and safety features are maintained.

In the electronics sector, these rods are utilized for manufacturing and repairing electronic housings, given their ability to create strong seals that can protect sensitive electronic components from environmental interference. Additionally, the packaging industry relies on thermoplastic welding rods to create strong, reliable seals on plastic packaging, ensuring the integrity of the products inside.

thermoplastic welding rod

Benefits of Using Thermoplastic Welding Rods

1. Strength and Durability One of the primary advantages of using thermoplastic welding rods is the strong bond they create. The fusion of the rod and the base thermoplastic ensures that the joint can withstand significant mechanical stress over time.

2. Ease of Use Thermoplastic welding is generally easier and faster compared to other joining methods. The rods can be melted quickly with hot air or a heat gun, and the process requires minimal setup. This efficiency is particularly beneficial in high-production environments.

3. Cost-Effectiveness The availability of thermoplastic welding rods in various materials and sizes allows manufacturers to choose cost-effective options without sacrificing quality. Since the welding process is also less labor-intensive, it translates into lower overall production costs.

4. Environmental Considerations Many thermoplastic materials are recyclable, and using these rods can enhance the sustainability of manufacturing processes. In cases of repair or modification, thermoplastic welding allows for the original materials to be reused rather than discarded, reducing waste.

5. Customization Thermoplastic welding rods can be tailored to meet specific applications, whether through the selection of material types or by modifying the diameter and length of the rods used. This customization capability supports innovative designs.

Conclusion

In summary, thermoplastic welding rods play a crucial role in modern manufacturing across various sectors. Their versatility, strength, cost-effectiveness, and ease of use make them the preferred choice for many applications. As industries continue to innovate and evolve, the importance of thermoplastic welding rods will only continue to grow, contributing to more efficient and sustainable production processes. Whether in construction, automotive, electronics, or packaging, understanding the properties and applications of thermoplastic welding rods is essential for those involved in the design and manufacturing of thermoplastic components.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025