Dec . 01, 2024 21:41 Back to list

pvc pipes and fittings

The Versatility and Benefits of PVC Pipes and Fittings

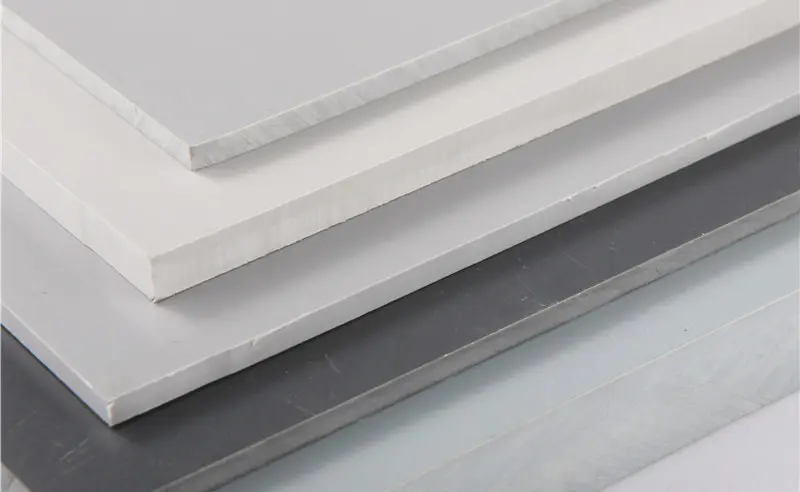

Polyvinyl chloride (PVC) pipes and fittings have become a cornerstone of modern plumbing and construction. Known for their durability, affordability, and ease of installation, PVC products are widely used across various applications, from residential plumbing to industrial processes. This article delves into the various advantages of PVC pipes and fittings, their applications, and the factors contributing to their increasing popularity.

What is PVC?

PVC is a synthetic plastic polymer that is lightweight and strong. It is one of the most produced plastic materials globally, owing to its versatility. In pipe production, manufacturers add additives to enhance properties such as impact resistance, flexibility, and UV stability, allowing for a wide range of applications.

Advantages of PVC Pipes and Fittings

1. Durability PVC pipes have an impressive lifespan, often exceeding 50 years. They resist corrosion, do not rot, and are not susceptible to rust, making them ideal for both indoor and outdoor use. Furthermore, they are immune to chemical damage, which is particularly advantageous in industrial applications where exposure to chemicals is common.

2. Lightweight Compared to traditional materials like metal or concrete, PVC is significantly lighter. This characteristic not only simplifies transportation and handling but also reduces installation costs, as less manpower is required to manage the pipes.

3. Cost-Effective PVC pipes are generally more affordable than their metal counterparts. The reduced material costs, combined with lower labor expenses due to easier installation, make them an economically sound choice for many projects.

4. Low Maintenance Due to their resistance to corrosion and chemical damage, PVC pipes require minimal maintenance over their lifespan. They do not need to be painted or treated to protect against deterioration, further reducing long-term costs.

5. Eco-Friendly Options Modern PVC manufacturing processes have become more environmentally friendly, and many products are now recyclable. While PVC itself is a plastic, advances in production technology allow for the incorporation of recycled materials.

pvc pipes and fittings

Applications of PVC Pipes and Fittings

The versatility of PVC has led to its incorporation in a wide range of applications

- Residential Plumbing PVC is commonly used for water supply lines, drainage systems, and venting. Its resistance to leaks and clogs makes it a reliable choice for homeowners.

- Industrial Uses PVC pipes can handle a variety of chemicals, making them suitable for industrial applications such as waste management and chemical transport. Their durability under extreme conditions is a valuable asset in these sectors.

- Irrigation Systems In agriculture, PVC pipes are widely used for irrigation systems, providing farmers with an effective means to deliver water to crops. The lightweight design and resistance to environmental factors are significant benefits in this context.

- Electrical Conduits Beyond plumbing, PVC is utilized for electrical conduits, protecting wiring from environmental and physical damage. This helps ensure the longevity and reliability of electrical systems.

Installation Considerations

While PVC pipes are user-friendly and straightforward to install, proper techniques must be followed to ensure optimal performance. The use of suitable adhesives and fittings is crucial for creating watertight seals. Additionally, understanding local building codes and regulations is essential, as these can vary by region and application.

Conclusion

PVC pipes and fittings are an integral part of modern infrastructure, offering unparalleled benefits in durability, cost-effectiveness, and versatility. Whether used in plumbing, construction, or industrial applications, their advantages make them a preferred choice for many professionals and consumers alike. As technology advances, the future of PVC in various industries looks promising, ensuring that it will continue to be a staple material for years to come.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025