Nov . 22, 2024 08:04 Back to list

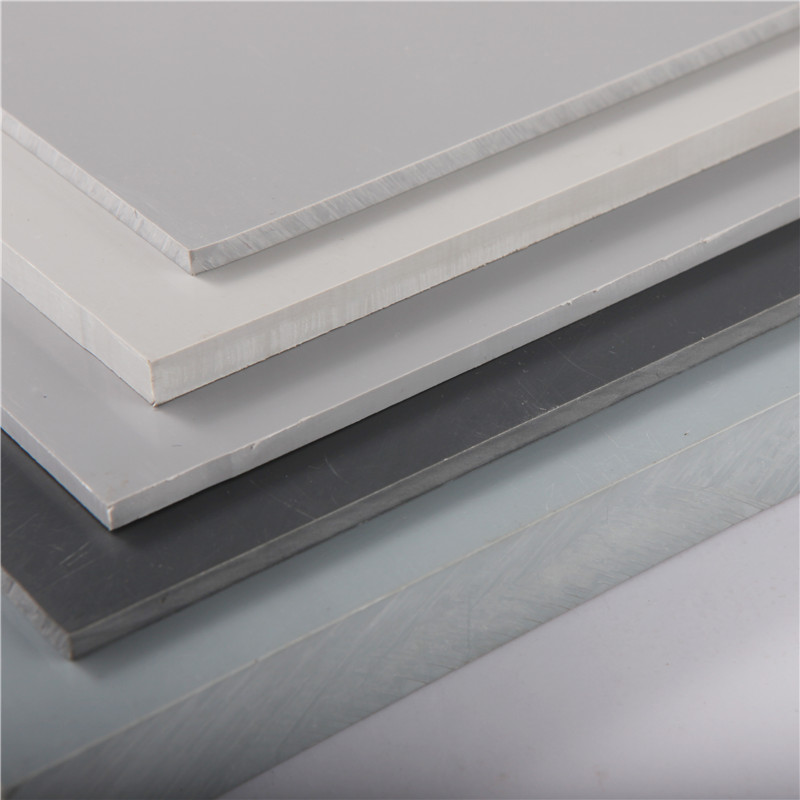

pvc embossed sheet

The Versatility and Applications of PVC Embossed Sheets

Polyvinyl chloride (PVC) is one of the most commonly used synthetic plastic polymers in the world. Renowned for its durability, versatility, and cost-effectiveness, PVC finds applications across various industries. Among the diverse products derived from PVC, embossed sheets stand out for their aesthetic appeal and functional attributes. This article delves into the characteristics, manufacturing processes, advantages, and applications of PVC embossed sheets, exploring their significance in modern design and construction.

Characteristics of PVC Embossed Sheets

PVC embossed sheets are distinguished by their textured surfaces, which offer visual and tactile benefits. The embossing process involves creating raised designs or patterns on the surface of the sheet, which can be tailored to suit specific aesthetic preferences or functional needs. These patterns not only enhance the visual appeal but also contribute to slip resistance and tactile interaction, making them popular in various applications.

One of the principal characteristics of PVC embossed sheets is their durability. Resistant to moisture, chemicals, and environmental stressors, they are suitable for both indoor and outdoor settings. The material also possesses good thermal insulation properties, which can help maintain comfortable temperatures in buildings.

Another noteworthy characteristic is the ease of maintenance. PVC embossed sheets can be cleaned with conventional cleaning agents, making them highly suitable for environments that require high hygiene standards, such as hospitals and kitchens.

Manufacturing Process

The manufacturing of PVC embossed sheets typically involves a series of well-defined steps. The process starts with the preparation of a PVC compound, which is then extruded into sheet form. During the extrusion process, heat is applied to melt the PVC, allowing it to flow through a die. Once the sheets are formed, they undergo a cooling process, after which the embossing is applied.

Embossing can be achieved through various methods, including roller embossing, where two engraved rollers press the pattern into the softened PVC surface. Alternatively, heat and pressure can be applied to create the desired texture. After embossing, the sheets are often treated with surface coatings or finishes to enhance their appearance and protective qualities.

Advantages of PVC Embossed Sheets

pvc embossed sheet

The use of PVC embossed sheets offers numerous advantages. First and foremost, their versatility makes them suitable for myriad applications, from flooring and wall cladding to signage and decorative elements. The customizable nature of the embossing patterns means that designers can create unique products tailored to specific needs, whether for residential, commercial, or industrial contexts.

Additionally, the cost-effectiveness of PVC embossed sheets cannot be overstated. When compared to materials like wood, metal, or glass, PVC embossed sheets are generally more affordable while delivering similar if not superior performance characteristics. This cost efficiency makes them an attractive choice for large-scale projects.

Furthermore, the lightweight nature of PVC embossed sheets simplifies transportation and installation, reducing labor costs and time on-site. Their flexibility and adaptability to various shapes and sizes also facilitate creativity in design and application.

Applications of PVC Embossed Sheets

The applications of PVC embossed sheets are extensive and varied. In the construction industry, they are often used for interior wall coverings, ceilings, and modular partitions, where their aesthetic and practical qualities enhance the overall design. In healthcare settings, their hygienic properties make them ideal for wall and flooring solutions, providing both cleanliness and visual appeal.

In the retail sector, PVC embossed sheets are frequently employed in signage, display units, and branding materials, leveraging their ability to draw attention while remaining practical. The automotive industry also utilizes these sheets in trim and interior components, where durability and ease of maintenance are paramount.

Moreover, in the realm of furniture design, PVC embossed sheets can be crafted into contemporary furniture pieces that are both stylish and functional, appealing to modern consumers seeking unique designs at an accessible price point.

Conclusion

In conclusion, PVC embossed sheets represent a fusion of functionality, aesthetics, and adaptability. Their various characteristics make them a favored choice across multiple industries, from construction to retail and beyond. As technology continues to advance, the manufacturing methods and applications of PVC embossed sheets will likely expand, further solidifying their place in the modern materials landscape. Whether enhancing interior spaces or serving as practical components in various products, PVC embossed sheets continue to prove their worth as a versatile and innovative material.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025