Jun . 13, 2024 13:22 Back to list

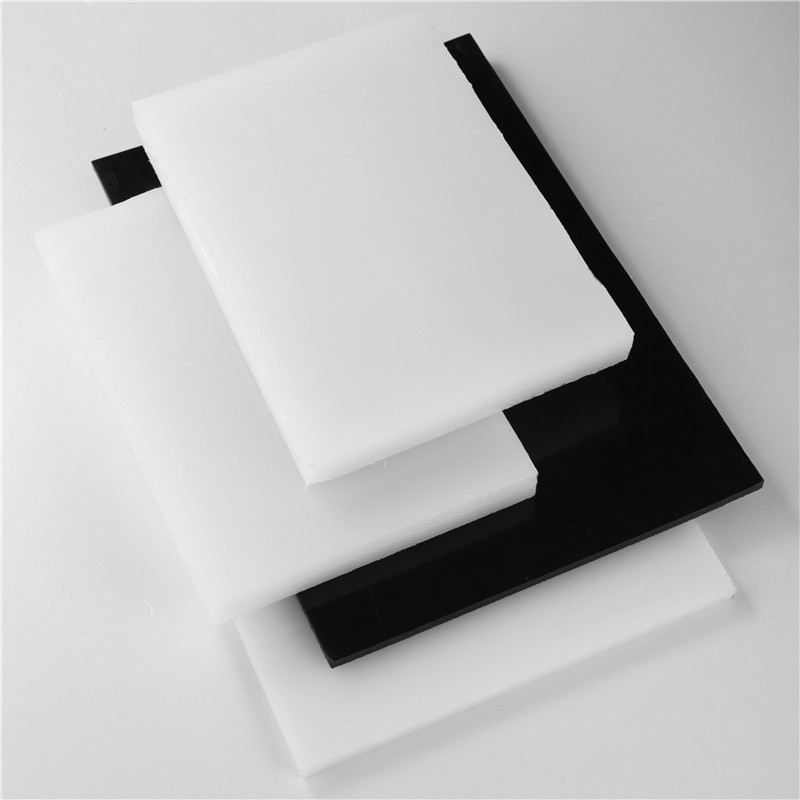

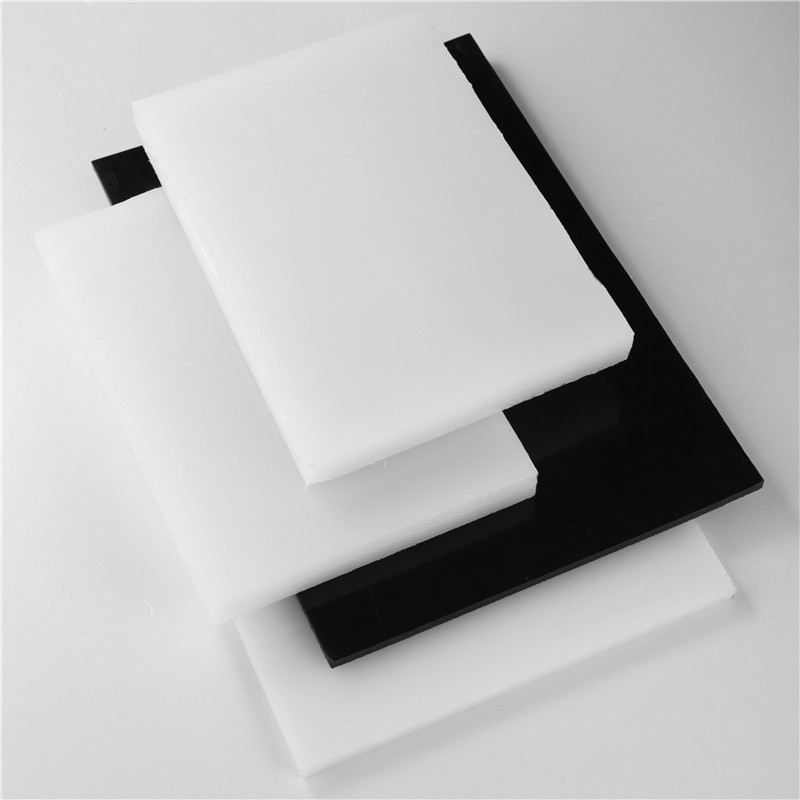

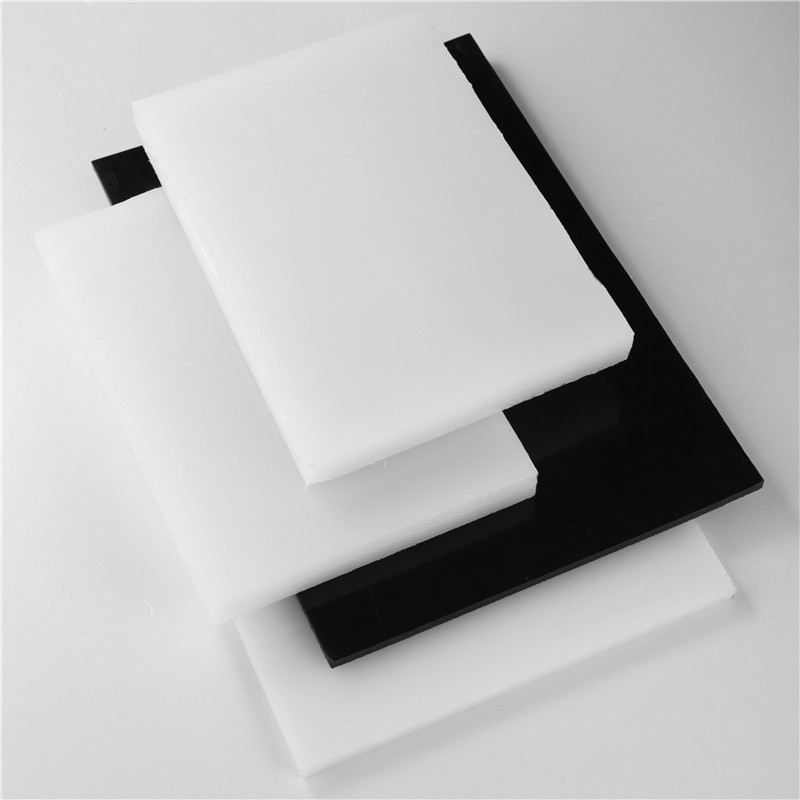

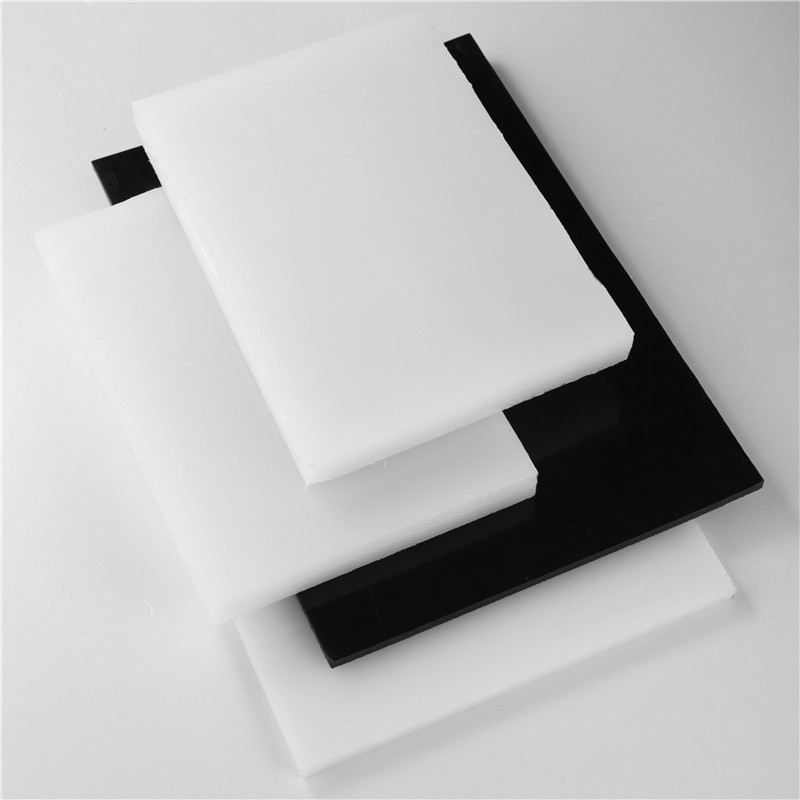

PVC sheet

Understanding PVC Plates Versatility and Applications

Polyvinyl Chloride (PVC), a synthetic plastic polymer, has revolutionized the manufacturing industry with its diverse applications. PVC plates are a prime example of this versatility, offering a unique blend of durability, affordability, and functionality that makes them a popular choice in various sectors.

PVC, derived from vinyl chloride monomer (VCM), is the world's third most widely produced synthetic plastic polymer, following polyethylene and polypropylene. PVC plates, formed by molding or extrusion processes, are a testament to the material's adaptability. They come in different forms - rigid, flexible, and foam - each catering to distinct needs.

Rigid PVC plates are known for their strength and rigidity, making them ideal for construction applications such as pipes, window frames, and wall panels. Their resistance to corrosion and chemicals, along with their low maintenance requirements, make them a cost-effective alternative to traditional materials like wood or metal.

Flexible PVC plates, on the other hand, have a more pliable nature, which allows them to be used in clothing, upholstery, and insulation. Their flexibility and durability also find use in flooring, medical devices, and food packaging, ensuring safety and hygiene standards are met.

Foam PVC plates, with their lightweight yet sturdy composition, are sought after in advertising and signage industries due to their ease of printing and fabrication. They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution

They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution pvc plate.

Beyond these standard uses, PVC plates have also found their way into the realm of art and innovation. Artists utilize them for sculptures, while engineers employ them in creating 3D printed prototypes. The recyclability of PVC further enhances its appeal, as it can be repurposed at the end of its life cycle, reducing waste and environmental impact.

However, like any material, PVC plates have their share of controversies. The production process releases hazardous chemicals, and the disposal of PVC products raises environmental concerns. Yet, continuous research and development in the industry strive to mitigate these issues, promoting sustainable practices and eco-friendly alternatives.

In conclusion, PVC plates, with their extensive range of uses and inherent properties, have become an indispensable part of our daily lives. They embody the potential of modern technology to provide practical solutions while acknowledging the need for sustainability. As we continue to explore new frontiers, the role of PVC plates in shaping our future remains an intriguing aspect of the plastics industry.

pvc plate.

Beyond these standard uses, PVC plates have also found their way into the realm of art and innovation. Artists utilize them for sculptures, while engineers employ them in creating 3D printed prototypes. The recyclability of PVC further enhances its appeal, as it can be repurposed at the end of its life cycle, reducing waste and environmental impact.

However, like any material, PVC plates have their share of controversies. The production process releases hazardous chemicals, and the disposal of PVC products raises environmental concerns. Yet, continuous research and development in the industry strive to mitigate these issues, promoting sustainable practices and eco-friendly alternatives.

In conclusion, PVC plates, with their extensive range of uses and inherent properties, have become an indispensable part of our daily lives. They embody the potential of modern technology to provide practical solutions while acknowledging the need for sustainability. As we continue to explore new frontiers, the role of PVC plates in shaping our future remains an intriguing aspect of the plastics industry.

They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution

They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution They're also used in interior design for decorative panels and furniture components, providing an eco-friendly and cost-efficient solution pvc plate.

Beyond these standard uses, PVC plates have also found their way into the realm of art and innovation. Artists utilize them for sculptures, while engineers employ them in creating 3D printed prototypes. The recyclability of PVC further enhances its appeal, as it can be repurposed at the end of its life cycle, reducing waste and environmental impact.

However, like any material, PVC plates have their share of controversies. The production process releases hazardous chemicals, and the disposal of PVC products raises environmental concerns. Yet, continuous research and development in the industry strive to mitigate these issues, promoting sustainable practices and eco-friendly alternatives.

In conclusion, PVC plates, with their extensive range of uses and inherent properties, have become an indispensable part of our daily lives. They embody the potential of modern technology to provide practical solutions while acknowledging the need for sustainability. As we continue to explore new frontiers, the role of PVC plates in shaping our future remains an intriguing aspect of the plastics industry.

pvc plate.

Beyond these standard uses, PVC plates have also found their way into the realm of art and innovation. Artists utilize them for sculptures, while engineers employ them in creating 3D printed prototypes. The recyclability of PVC further enhances its appeal, as it can be repurposed at the end of its life cycle, reducing waste and environmental impact.

However, like any material, PVC plates have their share of controversies. The production process releases hazardous chemicals, and the disposal of PVC products raises environmental concerns. Yet, continuous research and development in the industry strive to mitigate these issues, promoting sustainable practices and eco-friendly alternatives.

In conclusion, PVC plates, with their extensive range of uses and inherent properties, have become an indispensable part of our daily lives. They embody the potential of modern technology to provide practical solutions while acknowledging the need for sustainability. As we continue to explore new frontiers, the role of PVC plates in shaping our future remains an intriguing aspect of the plastics industry. Share:

Next:

Latest news

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025