Oct . 16, 2025 10:50 Back to list

PVC Rigid Sheet(UV Stabilized) | Weatherproof & Durable

PVC Rigid Sheet(UV Stabilized) is a key solution in the manufacturing industry, specifically within the plastic product industry and the Manufacturing of plastic sheets, pipes, and profiles. This article explores how Baoding Lida Plastic Industry Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- PVC Rigid Sheet(UV Stabilized) Overview

- Benefits & Use Cases of PVC Rigid Sheet(UV Stabilized) in Manufacturing of plastic sheets, pipes, and profiles

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on PVC Rigid Sheet(UV Stabilized) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(UV Stabilized) Overview

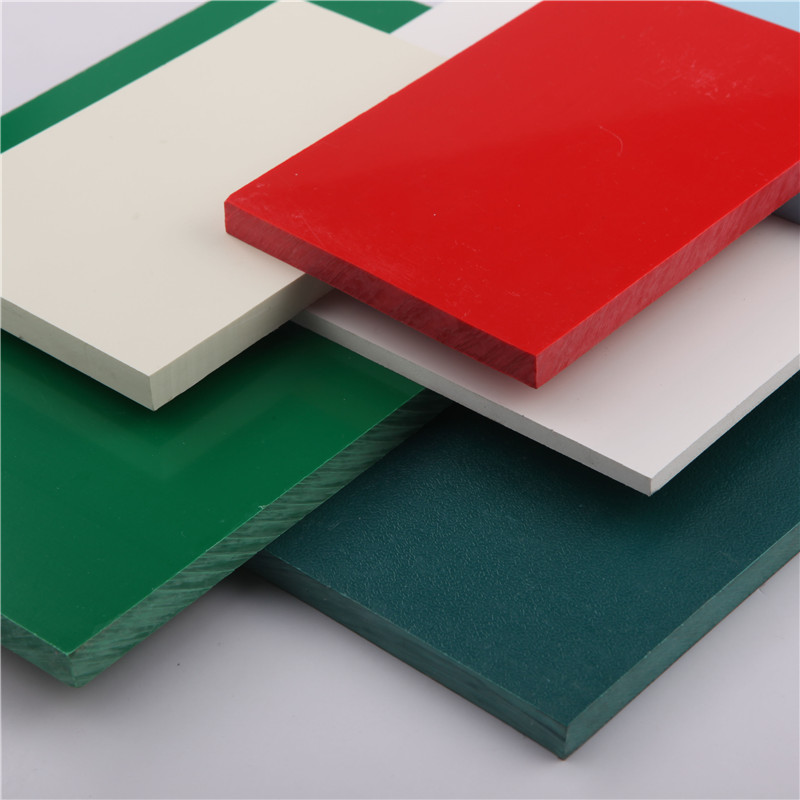

UV-stabilized PVC rigid sheet is an extruded, high-strength thermoplastic sheet engineered with UV inhibitors to resist yellowing, embrittlement, and surface chalking under prolonged sunlight and outdoor exposure. For B2B decision makers in the plastic product industry and in the Manufacturing of plastic sheets, pipes, and profiles, it delivers a dependable balance of mechanical strength, weatherability, and processability. Typical characteristics include high dimensional stability, excellent chemical resistance, and a self-extinguishing nature. PVC’s inherent flame resistance and the addition of UV stabilizers make it suitable for outdoor signage, cladding, protective panels, and enclosure components.

From a technical perspective, PVC rigid sheet commonly offers a density around 1.35–1.45 g/cm³, good tensile strength, and a Vicat softening temperature in the mid-70s °C range, supporting thermoforming, CNC routing, and bonding with industrial adhesives. Baoding Lida Plastic Industry Co., Ltd ensures consistent extrusion quality, tight thickness tolerances, and optional surface finishes to meet varied fabrication requirements. As a reliable manufacturer with deep experience in plastic sheet production, Baoding Lida delivers UV-stabilized grades designed to sustain multi-season outdoor performance while maintaining printability and clean edge quality after cutting.

Benefits & Use Cases of PVC Rigid Sheet(UV Stabilized) in Manufacturing of plastic sheets, pipes, and profiles

In the Manufacturing of plastic sheets, pipes, and profiles, UV-stabilized PVC rigid sheet is chosen for applications where outdoor durability and long-term color/impact retention are critical. Common use cases include exterior signboards and displays, architectural cladding and soffit panels, machine guards, electrical and telecom enclosures, chemical splash shields, and protective covers for HVAC or solar components. The material’s compatibility with printing, laminating, and adhesive bonding enables brand graphics and safety markings to remain legible over time.

Key advantages include UV resistance for prolonged outdoor life, chemical and corrosion resistance versus metal alternatives, high stiffness for stable panel performance, and consistent, low-warp fabrication behavior during CNC machining or thermoforming. Compared to materials like wood or some commodity plastics, PVC Rigid Sheet(UV Stabilized) offers lower moisture uptake, better flame retardancy, and a smoother surface for graphics. Baoding Lida Plastic Industry Co., Ltd supports OEMs and fabricators with custom sizes, colors, and surface textures, along with protective film options and processing guidance. This combination of material engineering and application expertise helps manufacturers reduce waste, improve assembly throughput, and standardize on a dependable substrate across product lines.

Cost, Maintenance & User Experience

Total cost of ownership for PVC Rigid Sheet(UV Stabilized) is favorable due to long service life outdoors, low maintenance needs, and straightforward fabrication. The UV stabilization package reduces premature fading and brittleness, decreasing replacement cycles and field service time. Fabricators appreciate the sheet’s consistent thickness and rigidity, which reduce machining rejects and tool wear. Maintenance is minimal—routine cleaning with mild detergents typically restores surface appearance, while the material’s chemical resistance helps it withstand common industrial environments.

B2B customers in signage, construction accessories, and enclosure manufacturing report fewer warranty claims related to color shift and cracking when transitioning to UV-stabilized grades. Many also note process efficiencies from reliable sheet flatness and predictable forming behavior, leading to improved yield and shorter lead times. When evaluating ROI, consider the avoided cost of repainting or re-facing outdoor panels, reduced downtime during replacements, and the ability to standardize printing or lamination processes. Baoding Lida Plastic Industry Co., Ltd’s quality control and customization options further enhance consistency across batches, supporting lean manufacturing objectives and better lifetime value.

Sustainability & Market Trends in manufacturing

Across manufacturing, sustainability expectations are rising alongside stricter quality and safety regulations. UV-stabilized PVC rigid sheet supports longer product lifecycles, meaning fewer replacements and lower material consumption over time. This durability, combined with the material’s recyclability in suitable streams, helps businesses align with circularity objectives. Compared with metals in certain applications, PVC sheets can reduce weight, transport energy, and corrosion-related maintenance. Many buyers also seek materials that can meet regulatory benchmarks such as RoHS and REACH compliance, and request low-VOC processing or lead-free stabilizer options.

Market demand is growing in outdoor infrastructure, smart city signage, renewable energy balance-of-system components, and modular construction—all areas where weatherable plastics deliver performance at scale. Baoding Lida Plastic Industry Co., Ltd invests in process optimization and material formulation to meet these trends, focusing on stable color retention, repeatable mechanical properties, and consistent surface quality for printing and bonding. By partnering with customers early in design, Baoding Lida helps specify the right PVC Rigid Sheet(UV Stabilized) grade for target lifespans and environmental conditions, enabling compliance, reduced waste, and measurable sustainability gains.

Conclusion on PVC Rigid Sheet(UV Stabilized) from Baoding Lida Plastic Industry Co., Ltd

PVC Rigid Sheet(UV Stabilized) offers a proven balance of outdoor durability, mechanical strength, and fabrication efficiency for the plastic product industry and the Manufacturing of plastic sheets, pipes, and profiles. With reliable UV resistance, clean machinability, and low maintenance, it supports lower total cost of ownership and consistent field performance. Baoding Lida Plastic Industry Co., Ltd stands out for quality extrusion, customization, and application support—helping B2B teams accelerate production and reduce risk.

Contact us: email: lidaplastic@ldsy.cn

Visit our website: https://www.lidaplastic.com

-

Durable and Efficient Sprinkler HDPE Pipe Solutions for Global Water Management

NewsNov.19,2025

-

Durable and Efficient HDPE Irrigation Pipe Fittings for Sustainable Water Management

NewsNov.19,2025

-

Efficient and Durable HDPE Pipe Sprinkler Systems for Modern Irrigation

NewsNov.18,2025

-

Durable and Efficient HDPE Sprinkler Pipe Fittings for Global Water Systems

NewsNov.18,2025

-

HDPE Sprinkler Pipe – Durable, Efficient Irrigation Solutions for Global Use

NewsNov.18,2025

-

Comprehensive Guide to PVC Pipe Coupling: Durable, Cost-Effective Piping Connections

NewsNov.17,2025