Aug . 30, 2024 03:03 Back to list

High-Quality PVC and PPR Pipes and Fittings for Reliable Plumbing Solutions

Understanding PVC and PPR Pipes and Fittings An Essential Guide

In the world of plumbing and construction, the choice of materials can greatly affect the durability and efficiency of a system. Two popular types of piping materials are PVC (Polyvinyl Chloride) and PPR (Polypropylene Random Copolymer). Each type has its unique properties, benefits, and applications, making them suitable for various projects in residential, commercial, and industrial settings.

PVC Pipes and Fittings

PVC is a thermoplastic material widely used in plumbing, drainage, and irrigation systems. One of the main advantages of PVC pipes is their resistance to corrosion and chemical degradation. This makes them an excellent choice for transporting water and other liquids without fear of contamination or deterioration. Additionally, PVC pipes are lightweight and easy to handle, which facilitates quick installation.

PVC fittings, such as elbows, tees, and couplings, provide the necessary connections to create a comprehensive piping system. These fittings are designed to ensure a tight seal, minimizing the risk of leaks. PVC pipes have a smooth interior surface that promotes efficient flow and reduces the likelihood of clogs. They can also be easily cut and joined using adhesives or solvent cement, making them highly versatile.

However, while PVC offers numerous benefits, it also has limitations. PVC pipes are not recommended for use in high-temperature applications, as prolonged exposure to heat can weaken the material. They are best suited for cold water supply and outdoor irrigation systems.

PPR Pipes and Fittings

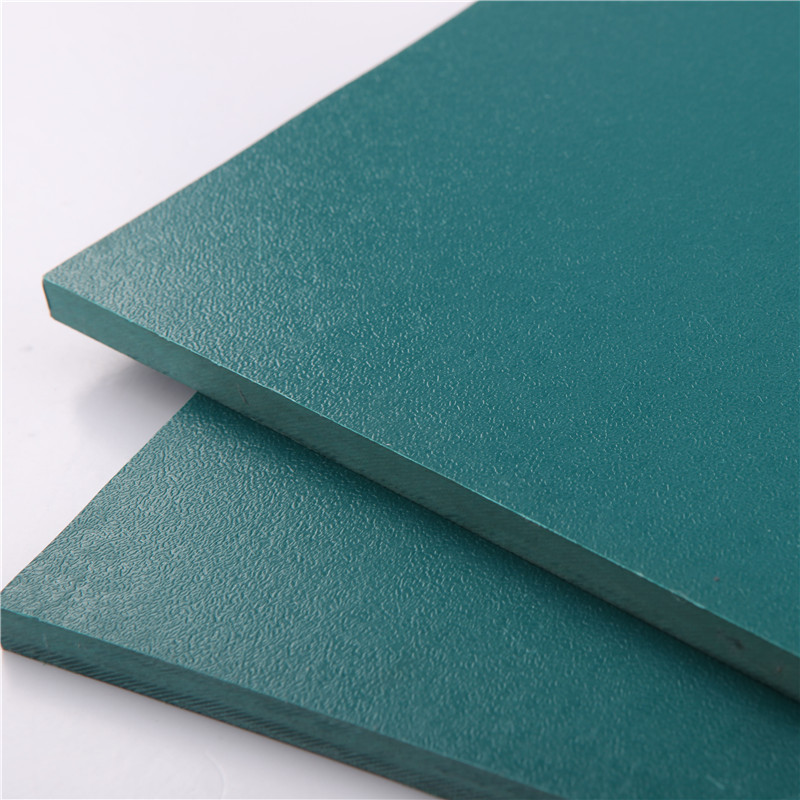

pvc ppr pipes and fittings

PPR pipes, on the other hand, are gaining popularity due to their superior thermal resistance and longevity. Made from polypropylene, PPR pipes can withstand higher temperatures, making them suitable for hot water supply systems. They have excellent resistance to chemicals, making them ideal for a variety of industrial applications.

One of the standout features of PPR pipes is their ability to be welded together, creating seamless joints that are highly resistant to leaks. This welding process results in a robust and durable piping system that can last for decades with minimal maintenance. PPR fittings are equally strong and come in various shapes and sizes to accommodate different plumbing requirements.

Moreover, PPR pipes are lightweight, which simplifies installation. They also have lower thermal conductivity, meaning they retain heat better than PVC pipes, making them an energy-efficient choice for hot water applications.

Comparative Analysis

When comparing PVC and PPR pipes, it is crucial to consider the specific needs of your project. PVC is generally more cost-effective for cold water applications and is preferred for outdoor plumbing systems, while PPR is ideal for hot water and industrial applications due to its durability and heat resistance.

In summary, both PVC and PPR pipes and fittings have distinct advantages that cater to various requirements in plumbing and construction. Understanding these materials helps in making informed decisions, ensuring that your plumbing system is not only efficient but also long-lasting. Whether opting for PVC or PPR, investing in quality materials will pay off in the long run, ultimately leading to a more effective and reliable infrastructure.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025