Dec . 12, 2024 10:45 Back to list

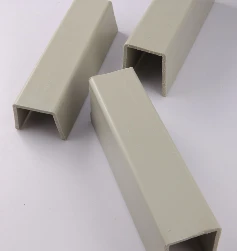

pp sheet

Understanding PP Sheets Versatility and Applications

Polypropylene (PP) sheets, a type of thermoplastic material, have gained immense popularity in various industries due to their distinctive properties and versatility. Produced from polypropylene resin, these sheets come in various thicknesses and sizes, making them suitable for a wide range of applications. This article delves into the characteristics, uses, and advantages of PP sheets, illuminating their importance in today’s manufacturing landscape.

Characteristics of PP Sheets

PP sheets are known for their lightweight and durable nature. They are resistant to impact, moisture, and chemicals, making them suitable for both indoor and outdoor applications. Furthermore, PP sheets have excellent tensile strength, which allows them to withstand significant stress without deforming. This strength, combined with their flexibility, makes them ideal for packaging solutions, automotive components, and construction materials.

Another notable feature of PP sheets is their design flexibility. They can be easily fabricated, cut, or shaped into various forms, and they can also be printed on without losing their integrity. This adaptability allows businesses to customize their products based on specific needs, enhancing both functionality and aesthetic appeal.

Applications of PP Sheets

PP sheets are employed in numerous sectors, including packaging, construction, automotive, and medical industries.

1. Packaging In the packaging sector, PP sheets are widely used for creating sturdy containers, boxes, and trays. Their resistance to moisture and chemicals ensures that products remain protected during transportation and storage. Companies often prefer PP sheets for food packaging because they are food-safe and can be recycled.

pp sheet

2. Construction In the construction industry, PP sheets are used as panels, cladding, and partitions. Their lightweight nature reduces structural load, while their durability ensures longevity even in harsh environmental conditions. Additionally, PP sheets can be utilized for insulation applications, offering both thermal and sound insulation properties.

3. Automotive The automotive sector benefits from PP sheets in various components such as interior panels, dashboards, and trims. The use of PP sheets reduces the overall weight of vehicles, leading to improved fuel efficiency. Furthermore, their chemical resistance ensures that they can withstand the exposure to automotive fluids and harsh cleaning agents.

4. Medical In the medical field, PP sheets are utilized for creating sterile packaging for medical devices and pharmaceuticals. Their ability to be easily sterilized makes them ideal for maintaining hygiene and safety standards.

Advantages of PP Sheets

The advantages of PP sheets are manifold

- Cost-Effective Compared to other materials, PP sheets are relatively inexpensive, allowing businesses to reduce costs without compromising quality. - Eco-Friendly Polypropylene is a recyclable material, making PP sheets an environmentally responsible choice. Many manufacturers are now using recycled PP sheets in their products, contributing to sustainability efforts. - Thermal Resistance PP sheets can withstand a wide range of temperatures, making them suitable for applications that require thermal stability.

Conclusion

In conclusion, PP sheets are an invaluable resource across various industries due to their unique properties and adaptability. Their lightweight yet durable nature, chemical resistance, and ease of fabrication make them a preferred choice for numerous applications. As industries continue to evolve and sustainability becomes a focal point, the demand for eco-friendly materials like PP sheets is expected to grow. Understanding the benefits and applications of PP sheets not only encourages responsible manufacturing practices but also highlights innovative solutions that meet the needs of modern consumers. Whether for packaging, construction, or automotive use, PP sheets represent a significant advancement in materials science, embodying efficiency and sustainability in one versatile product.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025