Nov . 18, 2024 11:19 Back to list

pp sandwich sheet

The Versatility of PP Sandwich Sheets

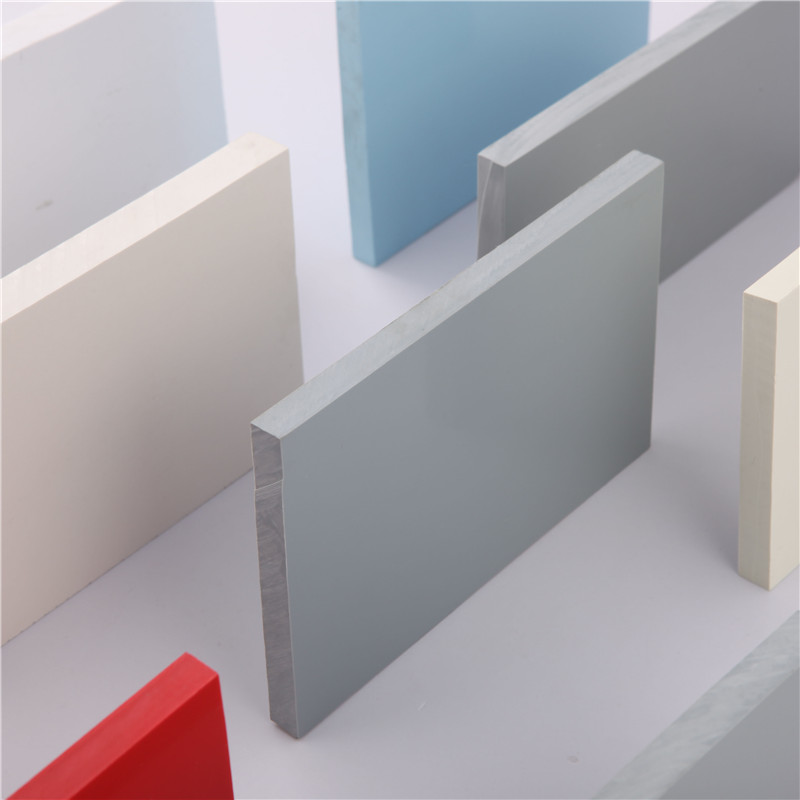

Polypropylene (PP) sandwich sheets have gained significant traction across various industries due to their unique properties and advantages. These innovative materials, characterized by their sandwich-like structure, consist of two outer layers of polypropylene that encapsulate a lightweight core. This design not only enhances their mechanical strength and thermal insulation capabilities but also makes them incredibly versatile for a wide range of applications.

What are PP Sandwich Sheets?

PP sandwich sheets are engineered sheets made up of multiple layers of polypropylene, strategically assembled to deliver improved performance compared to traditional materials. The core, usually composed of a lightweight material such as foam or polystyrene, provides excellent insulation while contributing to the overall rigidity of the sheet. The outer layers offer protection against environmental factors, ensuring durability and longevity. This combination of elements allows these sheets to retain their structural integrity even under challenging conditions.

Key Benefits

One of the most significant advantages of PP sandwich sheets is their lightweight nature, which facilitates easier handling and installation. This lightweight property also translates into lower transportation costs and improved fuel efficiency during shipping. Moreover, the sheets are highly resistant to moisture, chemicals, and UV radiation, making them suitable for both indoor and outdoor applications.

Another key benefit is their excellent thermal insulation capabilities. The structure of the sandwich sheet minimizes thermal transfer, making them ideal for use in refrigeration units, insulated panels, and building components where maintaining temperature is crucial. Their sound insulation properties also cannot be overlooked; PP sandwich sheets can help reduce noise transmission in commercial and residential buildings, enhancing comfort for occupants.

pp sandwich sheet

Applications Across Industries

The versatility of PP sandwich sheets has led to their adoption in a variety of sectors. In the construction industry, these sheets are increasingly used in wall panels, roofing, and interior finishes due to their lightweight and thermal insulation properties. They can be easily cut, shaped, and installed, providing architects and builders with design flexibility.

In the automotive sector, PP sandwich sheets are used in interior components, dashboards, and door panels where their lightweight profile contributes to fuel efficiency without compromising safety. The resistance of these sheets to chemicals is particularly advantageous in cars, where exposure to various substances is common.

PP sandwich sheets also find applications in the packaging industry. The materials are utilized for manufacturing crates, pallets, and other containers that require strength and durability, yet remain lightweight. Their recyclability further enhances their appeal to environmentally conscious manufacturers, aligning with sustainable practices in packaging solutions.

Conclusion

The rise in popularity of PP sandwich sheets is a testament to their adaptability and practicality in modern applications. With benefits ranging from thermal insulation and lightweight construction to chemical resistance and sound absorption, it’s no surprise that these sheets are being embraced across various industries. As technological advancements continue to enhance their properties and expand their range of applications, PP sandwich sheets are poised to play an even more significant role in the future of material science. Whether for construction, automotive, or packaging purposes, the versatility of PP sandwich sheets serves as a foundational element for innovative solutions in today's fast-paced world. By understanding their properties and potential, businesses and consumers alike can leverage these materials for improved performance and sustainability.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025