Dec . 03, 2024 18:42 Back to list

Exploring the Applications and Advantages of PPR Pipe Systems in Modern Construction

Understanding PPR Tubes The Future of Plumbing Solutions

Plastic piping has become a cornerstone of modern plumbing, and among the various materials available, Polypropylene Random Copolymer (PPR) tubes have gained significant traction in both residential and commercial applications. Characterized by their durability, resistance to corrosion, and cost-effectiveness, PPR tubes offer a compelling alternative to traditional metal pipes.

What are PPR Tubes?

PPR tubes are made from a type of plastic known as polypropylene, which is modified with random copolymers to enhance its properties. This engineering results in a lightweight yet robust tube that can withstand high temperatures and pressures, making it suitable for a variety of plumbing needs. PPR pipes are often used in hot and cold water systems, heating installations, and even for the transport of chemicals.

Benefits of PPR Tubes

1. Durability and Longevity One of the primary advantages of PPR tubes is their impressive lifespan. They are resistant to corrosion, scaling, and chemical effects, which means they do not degrade over time like metal pipes. Their ability to withstand extreme temperatures—from as low as -20°C to as high as 95°C—further amplifies their durability.

2. Ease of Installation PPR tubes are lightweight and easy to handle, reducing labor costs associated with installation. They can be easily cut, joined, and shaped, allowing for versatile plumbing designs. The fusion welding technique used to connect PPR pipes creates a seamless joint that is as strong as the pipe itself, ensuring a leak-proof system.

3. Cost-Effectiveness Although the initial investment in PPR tubes may be slightly higher than PVC options, their longevity, reduced maintenance costs, and energy efficiency make them a more economical choice in the long run. With lesser energy loss during hot water transfer compared to metal pipes, homeowners can expect lower energy bills.

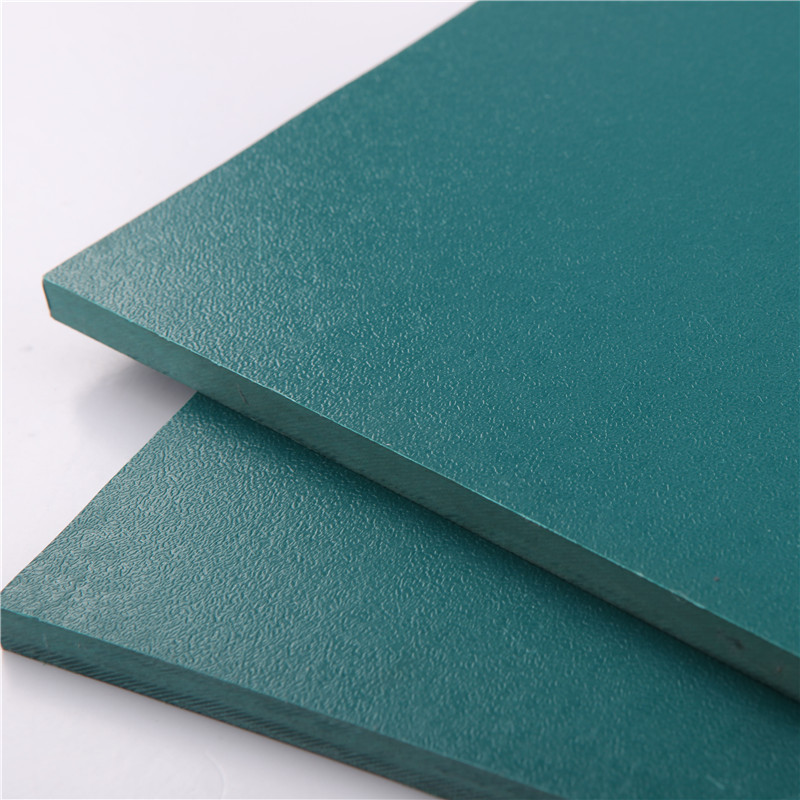

ppr tube

4. Health and Safety PPR tubes are known to be non-toxic and environmentally friendly. They do not leach harmful substances, which makes them an excellent choice for drinking water systems. Furthermore, the smooth interior surface of PPR pipes helps to reduce the accumulation of bacteria and biofilms, enhancing water quality and safety.

5. Resistance to Environmental Factors Unlike metal pipes that may rust or corrode when exposed to moisture or chemicals, PPR tubing is impervious to such environmental stressors. This makes them particularly advantageous in chemical industries as well as in moist environments where corrosion is a risk.

Applications of PPR Tubes

The versatility of PPR tubes allows them to be utilized in various applications. In residential settings, they are often used in heating systems, potable water supply lines, and drainage systems. In commercial and industrial settings, PPR pipes are employed for process piping, chemical transport, and HVAC systems due to their reliability and resistance to chemical attacks.

Future Prospects

As sustainability becomes increasingly important, the demand for eco-friendly plumbing solutions is rising. PPR tubes, being recyclable and energy-efficient, are well-positioned to meet this demand. With ongoing advancements in manufacturing techniques and an increasing emphasis on sustainable building practices, PPR tubes are likely to play a crucial role in the plumbing industry moving forward.

Conclusion

In conclusion, PPR tubes represent a modern, efficient, and sustainable solution for plumbing requirements. Their unique properties provide numerous benefits over traditional materials, paving the way for their widespread adoption across various sectors. As the industry continues to evolve, PPR tubes are set to remain at the forefront of innovative plumbing solutions, offering reliability and efficiency for years to come.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025