Nov . 26, 2024 08:10 Back to list

ppr pipes and fittings

Understanding PPR Pipes and Fittings An Overview

In the modern world, the efficiency and effectiveness of plumbing systems are paramount, especially in residential, commercial, and industrial applications. A significant player in this domain is PPR (Polypropylene Random Copolymer) pipes and fittings, which have gained immense popularity due to their unique properties and advantages. This article delves into the characteristics, benefits, applications, and installation practices associated with PPR pipes and fittings.

What are PPR Pipes and Fittings?

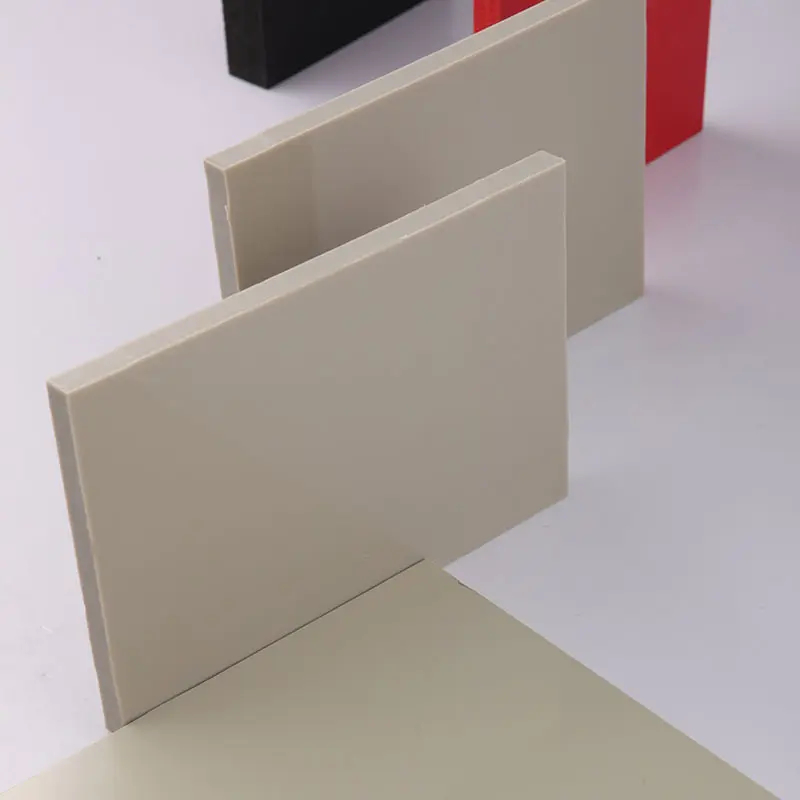

PPR pipes are made from a type of polypropylene known as Random Copolymer, which is specifically designed for piping systems. These pipes are available in various diameters and wall thicknesses, accommodating a wide range of water flow rates. PPR fittings are the components that connect the pipes, ensuring a leak-free, robust system capable of withstanding high pressures and temperatures.

Key Characteristics

PPR pipes and fittings are known for their impressive physical and chemical properties

1. Durability PPR is inherently resistant to corrosion, scaling, and chemical damage, making it a long-lasting choice for plumbing systems. Unlike metal pipes, PPR does not rust, ensuring a cleaner water supply.

2. Temperature Resistance PPR pipes can handle temperatures ranging from -20°C to 95°C, making them suitable for both hot and cold water systems. This temperature resilience is critical in applications such as heating systems and industrial processes.

3. Lightweight Compared to traditional materials like steel or copper, PPR pipes are significantly lighter, which simplifies handling and installation. This characteristic also reduces transportation costs.

4. Low Thermal Conductivity PPR’s low thermal conductivity helps maintain the temperature of fluids inside the pipes, contributing to energy efficiency in heating systems.

5. Non-Toxic PPR is a non-toxic material that does not leach harmful chemicals into the water, ensuring the safety and health of drinking water systems.

Advantages of PPR Pipes

The advantages of using PPR pipes and fittings extend beyond their physical characteristics

- Cost-Effective While the initial cost may be slightly higher than traditional materials, the long-lasting nature and low maintenance requirements of PPR systems offer significant cost savings over their lifetime.

- Easy Installation PPR pipes can be joined using fusion welding techniques, providing a seamless and strong connection that eliminates the risk of leaks. Their lightweight nature also speeds up the installation process.

ppr pipes and fittings

- Versatility PPR pipes and fittings are versatile

. They can be used in various applications such as potable water systems, heating systems, and industrial applications, making them a preferred choice for engineers and contractors.- Environmental Impact PPR is a recyclable material, making it an environmentally friendly option for piping solutions. Its long lifespan reduces the frequency of replacements, which further contributes to sustainability.

Applications

PPR pipes and fittings are widely used across different sectors

- Residential Plumbing In homes, they are popular for both hot and cold water supply systems, as well as for underfloor heating applications.

- Commercial Systems PPR pipes are often used in large commercial buildings for efficient plumbing and heating solutions.

- Industrial Applications Industries use PPR pipes for transporting chemicals and liquids due to their resistance to corrosion and chemical attacks.

Installation Practices

Proper installation is essential for maximizing the benefits of PPR pipes and fittings

1. Cutting and Preparation Ensure that the pipes are cut cleanly and that the ends are smooth to facilitate proper welding.

2. Welding Process Use an appropriate fusion welding machine to join the pipes and fittings. This process requires precise temperature control and timing to create a solid bond.

3. Pressure Testing Once installed, the system should be pressure-tested to identify any leaks or weak spots before being put into service.

4. Regular Maintenance Although PPR pipes require less maintenance than other materials, periodic inspections can help ensure long-term performance.

Conclusion

PPR pipes and fittings represent a significant advancement in plumbing technology, offering a combination of durability, safety, and cost-effectiveness. Their versatility makes them suitable for a wide range of applications, from residential to industrial systems. As the demand for efficient and sustainable plumbing solutions continues to grow, PPR pipes and fittings are likely to play an increasingly vital role in the future of piping technology.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025