Nov . 12, 2024 03:00 Back to list

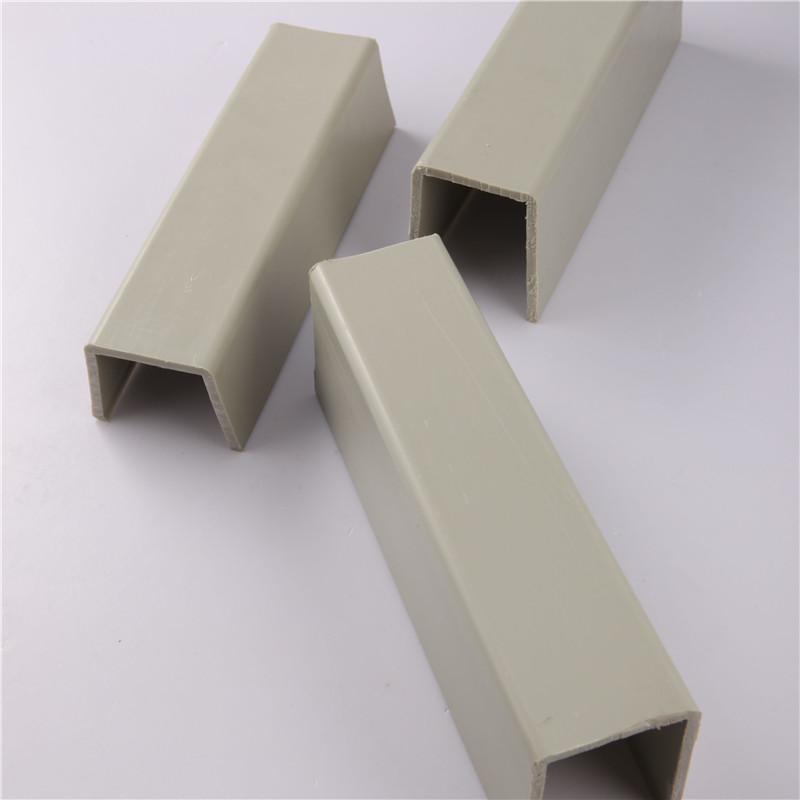

ppr pipe fittings

Understanding PPR Pipe Fittings A Comprehensive Guide

PPR (Polypropylene Random Copolymer) pipes and fittings are increasingly popular in plumbing and construction due to their durability, resistance to corrosion, and lightweight properties. These fittings, specifically designed for use with PPR pipes, play a crucial role in ensuring efficient and reliable plumbing systems. This article will explore the various aspects of PPR pipe fittings, including their advantages, applications, installation methods, and maintenance tips.

What are PPR Pipe Fittings?

PPR pipe fittings are components used to connect, direct, or terminate PPR pipes in a plumbing system. They are made from polypropylene random copolymer, a thermoplastic material known for its resilience and flexibility. Common types of PPR fittings include elbows, tees, reducers, caps, and couplings, each serving a unique function in a plumbing or heating installation.

Advantages of PPR Pipe Fittings

1. Durability PPR fittings are resistant to rust, corrosion, and scale formation, making them ideal for both hot and cold water applications. Their robust nature ensures a long lifespan, often exceeding 50 years with proper installation and maintenance.

2. Health and Safety Unlike metal pipes, PPR fittings do not leach harmful substances into the water supply. They are free from toxic chemicals such as bisphenol A (BPA), ensuring safe drinking water.

3. Cost-Effectiveness While the initial cost of PPR systems can be higher than traditional materials like PVC or metal pipes, their longevity and low maintenance requirements result in substantial savings over time.

4. Thermal Insulation PPR fittings provide excellent thermal insulation, reducing heat loss in hot water systems and preventing condensation in cold water systems. This characteristic contributes to overall energy efficiency.

5. Lightweight The lightweight nature of PPR fittings simplifies handling and installation compared to heavier materials. This aspect can considerably reduce labor costs and installation time.

Applications of PPR Pipe Fittings

PPR pipe fittings are widely utilized in various applications, including

ppr pipe fittings

- Residential Plumbing Ideal for supplying hot and cold water in homes, PPR fittings are used in kitchen, bathroom, and outdoor plumbing systems. - HVAC Systems These fittings are also suitable for heating and cooling systems, ensuring efficient fluid flow without the risk of leaks. - Industrial Use PPR fittings can withstand harsh chemicals and temperatures, making them suitable for industrial applications such as transporting chemicals and other fluids. - Irrigation Systems In agricultural practices, PPR fittings are commonly used for irrigation systems due to their resistance to corrosion and adverse weather conditions.

Installation of PPR Pipe Fittings

Installing PPR fittings requires some specific techniques to ensure a secure and leak-free connection

1. Cutting the Pipe Use a pipe cutter to achieve a clean and square cut on the PPR pipe, removing any burrs that may create leaks when fittings are installed.

2. Heating PPR fittings are typically joined through a heat fusion process. Using a specialized fusion machine, heat both the fitting and the pipe until they reach the appropriate temperature, usually around 260°C (500°F).

3. Joining Quickly insert the heated pipe into the fitting while rotating gently to ensure a complete connection. Hold the assembly together for a few seconds to allow the material to fuse.

4. Cooling Allow the fused joint to cool naturally without any movement. This process ensures that a strong bond is formed.

Maintenance of PPR Pipe Fittings

One of the main advantages of PPR systems is their low maintenance requirements. However, periodic checks are advisable

- Visual Inspection Regularly check for any signs of wear or damage to fittings, particularly at connection points. - Temperature Control Ensure that the system operates within the recommended temperature ranges to prolong the lifespan of the fittings. - Cleaning Avoid the use of harsh chemicals for cleaning, which may degrade the fittings over time.

Conclusion

PPR pipe fittings are an excellent choice for modern plumbing systems, offering multiple advantages over traditional materials. Their durability, resistance to corrosion, and ease of installation make them a preferred option for both residential and industrial applications. By understanding their properties and maintenance needs, users can ensure the longevity and efficiency of their plumbing systems, making PPR fittings a worthwhile investment for any construction project.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025