Dec . 04, 2024 07:52 Back to list

Understanding PPR Pipe Characteristics and Applications in Modern Plumbing Systems

Understanding PPR Pipes A Comprehensive Overview

PPR pipes, or Polypropylene Random Copolymer pipes, have gained significant popularity in various plumbing and industrial applications due to their unique properties and advantages. These pipes are made from a high-quality thermoplastic polymer, which is renowned for its durability, resistance to corrosion, and affordability. This article will delve into the characteristics, benefits, applications, and installation techniques of PPR pipes to provide a comprehensive understanding of this versatile piping solution.

Characteristics of PPR Pipes

PPR pipes are characterized by their lightweight, high tensile strength, and low thermal conductivity. Unlike traditional metal pipes, which can corrode over time, PPR pipes do not rust or deteriorate, making them a reliable choice for water supply and drainage systems. The smooth inner surface of PPR pipes minimizes flow resistance, enhancing the efficiency of fluid transport. Moreover, they are available in various sizes and pressure ratings, allowing for a wide range of applications.

Benefits of PPR Pipes

One of the primary advantages of PPR pipes is their resistance to chemical corrosion. They can withstand exposure to various chemicals without compromising their structural integrity, making them ideal for chemical and wastewater applications. Additionally, PPR pipes demonstrate excellent temperature resistance, withstanding temperatures of up to 95 degrees Celsius (203 degrees Fahrenheit) for hot water applications.

Another noteworthy feature is their lower environmental impact. PPR pipes are fully recyclable, contributing to sustainable building practices. The energy consumption associated with their production is relatively low compared to traditional materials. Furthermore, due to their durability and long lifespan—often exceeding 50 years—PPR pipes reduce the need for frequent replacements, which in turn lowers overall waste.

Applications of PPR Pipes

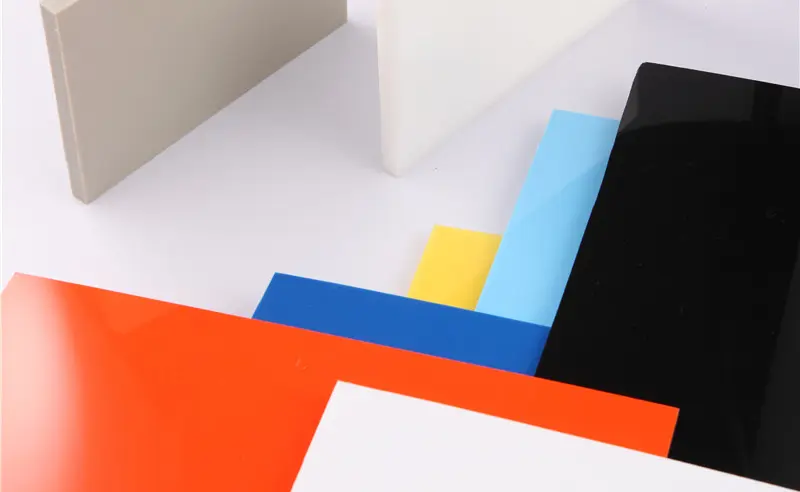

ppr pipe

PPR pipes are suited for various applications, primarily in residential and commercial plumbing. They are widely used for hot and cold water distribution systems, as well as in heating systems, like underfloor heating. Additionally, PPR pipes are an excellent choice for irrigation systems in agricultural settings, given their resistance to chemical fertilizers and other substances.

In industrial applications, PPR pipes are utilized for transporting aggressive fluids, including chemicals and food products. The hygienic properties of PPR make it a preferred material in food processing plants, ensuring safe and clean transport.

Installation Techniques

Installing PPR pipes requires specific techniques to maximize their performance and longevity. One of the most common methods is heat fusion, where pipe ends are heated to a certain temperature and then joined together. This creates a strong, homogeneous bond that eliminates leaks at the joints. It is crucial to maintain the appropriate temperature during the heating process to avoid damaging the pipes.

Proper cutting and preparation of the pipe ends are essential for a successful joint. It is also advisable to use specialized tools designed for PPR pipe installation to ensure precision and reduce the risk of contamination during the process.

Conclusion

PPR pipes are a modern solution for various plumbing and industrial needs, offering a range of benefits from durability and chemical resistance to environmental sustainability. As industries and consumers increasingly focus on sustainable practices, the demand for PPR pipes is likely to grow. Their versatility in application combined with their many performance advantages makes them an ideal choice for anyone looking to invest in reliable and efficient piping systems.

In summary, whether you are a homeowner, contractor, or industrial operator, understanding the capabilities and benefits of PPR pipes can guide you in making informed decisions for your plumbing and piping requirements.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025