Dec . 10, 2024 19:28 Back to list

PP Embossed Sheets for Enhanced Texture and Design Applications

Understanding PP Embossed Sheets Features and Applications

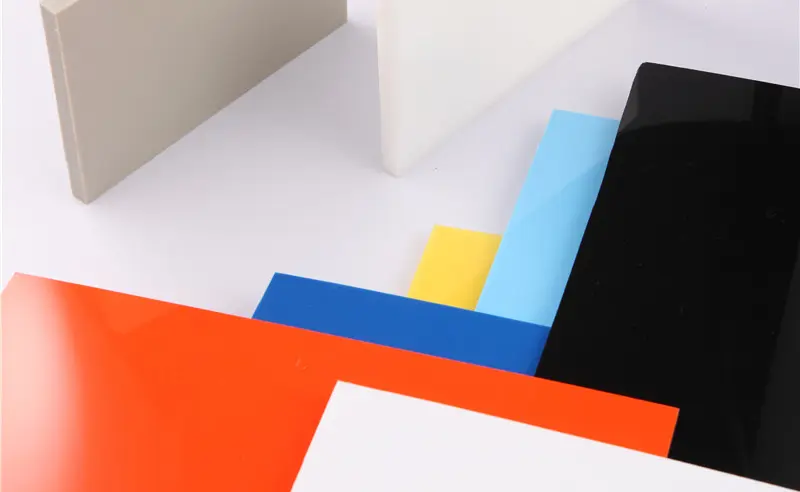

Polypropylene (PP) embossed sheets have gained significant attention across various industries due to their unique properties and diverse applications. These sheets are created by processing polypropylene resin through an embossing technique, which results in a textured surface. This article explores the characteristics, manufacturing process, and applications of PP embossed sheets.

Characteristics of PP Embossed Sheets

One of the standout features of PP embossed sheets is their lightweight nature. Compared to other materials, polypropylene offers a lower density, making it easier to handle and ship. This property is particularly beneficial in industries where weight savings can lead to cost reductions in logistics.

Another notable characteristic is the excellent chemical resistance of polypropylene. PP embossed sheets can withstand exposure to a variety of chemicals, including acids and bases, making them suitable for use in laboratories and industrial environments. This chemical resilience ensures longevity and durability, even under harsh conditions.

Moreover, PP embossed sheets have good impact resistance, which helps them maintain structural integrity even when subjected to stress or physical force. The embossed texture not only enhances their aesthetic appeal but also provides improved grip and slip resistance, making these sheets suitable for applications requiring safety features.

Manufacturing Process

The production of PP embossed sheets involves several critical steps. First, polypropylene resin is melted and extruded through a flat die to form a thin sheet. While still hot and pliable, the sheet is passed through an embossing roller that creates the desired texture on one or both surfaces of the sheet. This process can be adjusted to achieve different patterns and finishes, providing versatility in design.

pp embossed sheet

After the embossing process, the sheets are cooled, cut to size, and rolled or stacked for packaging and distribution. Quality control measures are implemented throughout the manufacturing process to ensure that the sheets meet industry standards and client specifications.

Applications of PP Embossed Sheets

PP embossed sheets are finding applications in various sectors due to their advantageous properties. In the packaging industry, they are used to create attractive, durable containers and packaging solutions. Their lightweight nature and chemical resistance make them ideal for products that require protection from external elements.

In the automotive sector, PP embossed sheets are utilized for interior panels and trim. The aesthetic quality of the embossed texture enhances the visual appeal of vehicle interiors while providing a lightweight alternative to traditional materials. Additionally, their impact resistance contributes to overall safety and durability in automotive applications.

Another notable application is in construction and architecture. PP embossed sheets are often used as wall cladding, roofing materials, and insulation due to their thermal stability and ability to resist moisture. The artistic potential of embossed patterns also allows for innovative designs in architectural projects.

Moreover, in the healthcare sector, PP embossed sheets are employed to manufacture medical devices and equipment. Their chemical resistance and ease of sterilization make them suitable for use in sterile environments, further extending their applicability.

Conclusion

In summary, PP embossed sheets are versatile materials that offer an array of benefits, including lightweight properties, chemical resistance, and impact durability. Their unique texture not only enhances aesthetic appeal but also provides functional advantages across multiple industries. As manufacturing technologies improve and the demand for innovative materials continues to grow, the importance of PP embossed sheets in various applications will likely increase, paving the way for new developments and uses in the future.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025