Sep . 21, 2025 07:55 Back to list

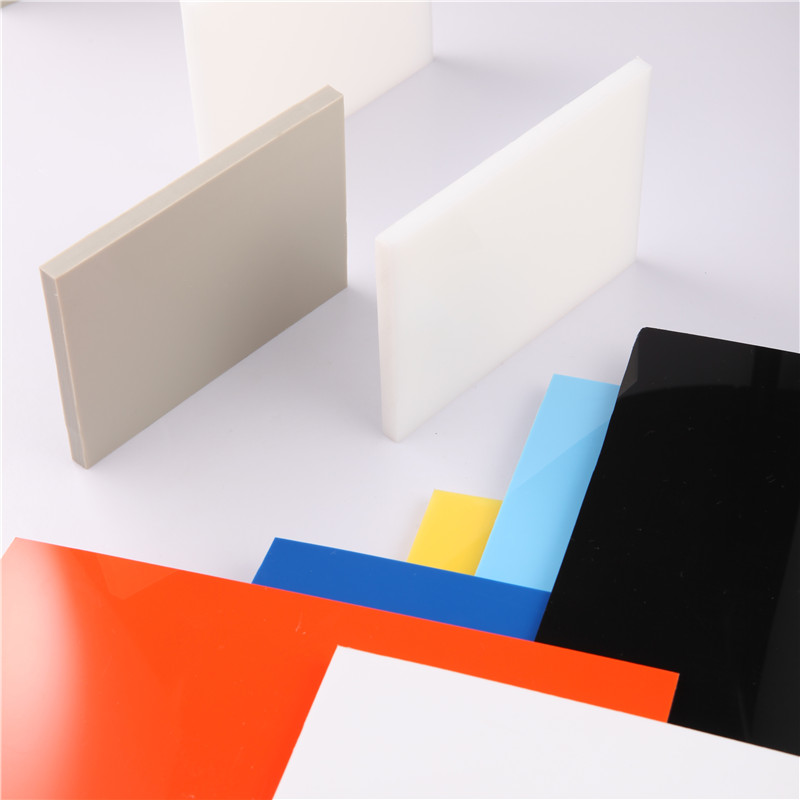

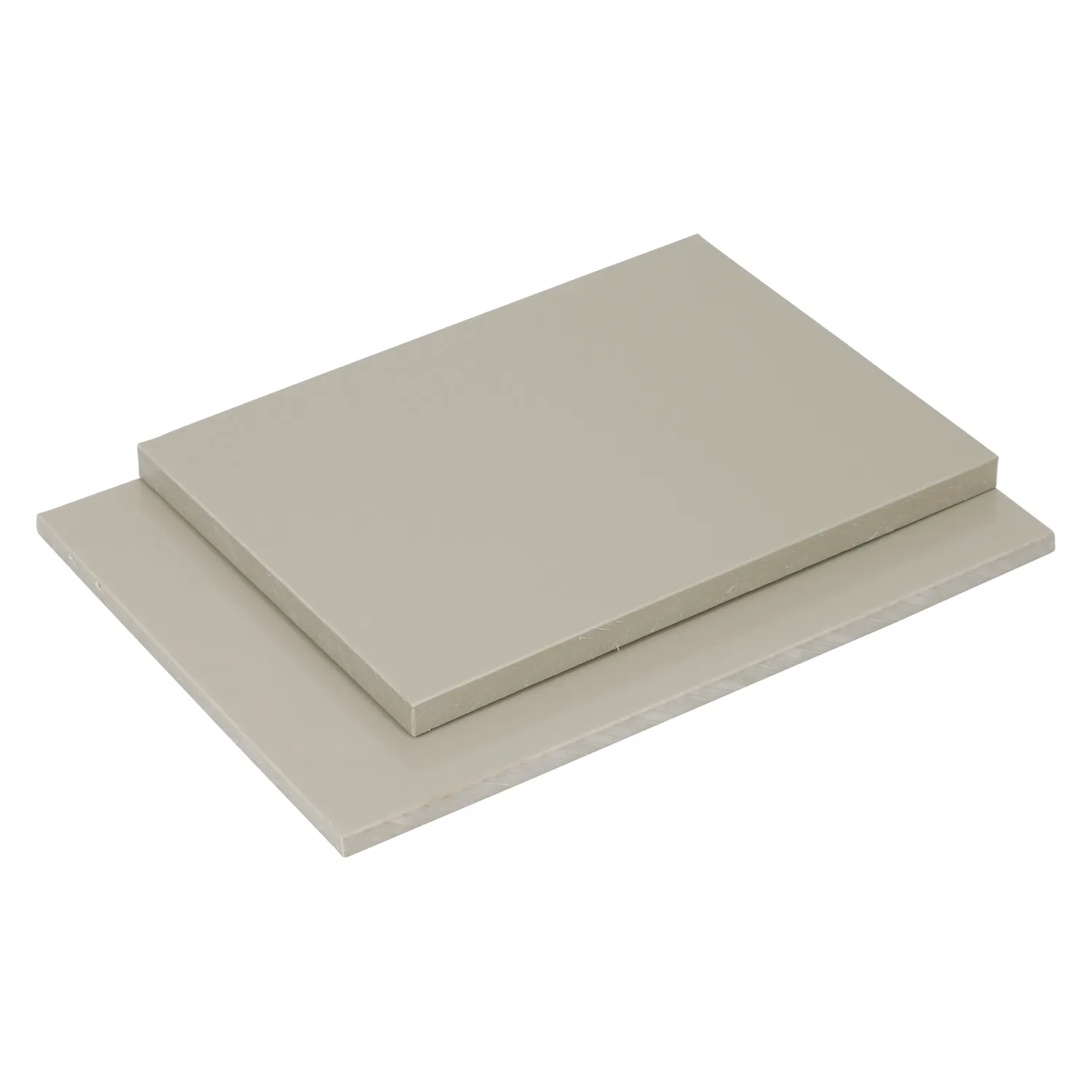

PP Rigid Sheet (Glossy Surface) - Superior Quality & Finish

Navigating Chinaplas: Unveiling China's Top Plastic Sheet & PVC Board Innovators

A B2B Deep Dive into the Future of Materials and Manufacturing

Introduction: The Pulse of Global Plastics at Chinaplas

Each year, Chinaplas stands as the undisputed global beacon for the plastics and rubber industries, drawing in innovators, manufacturers, and decision-makers from every corner of the world. It’s more than just an exhibition; it’s a vibrant marketplace of ideas, a launchpad for groundbreaking technologies, and a crucial nexus for forging strategic partnerships. While the spotlight often shines on advancements in flexible packaging films and custom-made plastic bags, Chinaplas equally serves as a critical platform for manufacturers specializing in foundational materials like high-performance plastic sheets and robust PVC boards.

For B2B buyers and industry leaders, Chinaplas offers an unparalleled opportunity to explore the cutting edge of material science and manufacturing processes. It’s where the future of diverse applications – from construction and automotive to signage and advanced packaging components – begins to take shape, driven by innovations in rigid plastics. This year, the focus intensifies on how Chinese manufacturers are not only meeting but exceeding global standards, particularly in specialized products like PP rigid sheet with a glossy surface, which offers a unique blend of aesthetic appeal and functional performance.

Understanding the landscape of leading Chinese manufacturers in the plastic sheet and PVC board sector at Chinaplas is essential for any business looking to optimize supply chains, enhance product quality, and drive sustainable growth in a competitive global market.

Industry Trend Spotlight: Sustainability, Performance, and Digital Transformation

The global plastics industry is undergoing a transformative shift, with three major forces dictating the pace of innovation: sustainability, high-performance material demands, and the integration of smart manufacturing technologies. This is particularly evident in the realm of plastic sheet and PVC board production.

- ✓ Eco-Friendly Materials: There's an increasing demand for eco-friendly solutions, even in rigid plastics. This includes materials that are easily recyclable, incorporate post-consumer recycled (PCR) content, or are developed with biodegradable properties. For PP rigid sheets and PVC boards, this translates into lightweighting initiatives, enhanced durability for longer product life cycles, and the development of formulations that support a circular economy.

- ✓ High-Performance & Customized Solutions: Beyond sustainability, industries demand materials with superior mechanical strength, chemical resistance, UV stability, and specific aesthetic qualities. For instance, a PP rigid sheet with a glossy surface isn't just about appearance; it signifies a material engineered for specific applications requiring both visual appeal and robust functionality, such as in high-end signage, display boards, or specialized packaging inserts. Customization in multi-layer structures and specialized formulations is gaining global attention, enabling solutions tailored for specific environmental conditions or end-use requirements.

- ✓ Market Growth Drivers: The global flexible packaging market, which often utilizes rigid plastic components for support or specialized inserts, is projected for steady growth. This growth is significantly driven by e-commerce expansion, demanding innovative and protective packaging solutions, and evolving consumer demand for convenience and sustainability. Despite regulatory pressures on single-use plastics, the demand for essential, high-performing plastic materials like PP rigid sheets and PVC boards in durable goods, construction, and industrial applications remains robust, adapting to new eco-conscious parameters.

- ✓ Emerging Focus Areas: Chinaplas highlights sustainable and high-performance plastic materials, circular economy solutions in packaging and industrial applications, and the rapid adoption of smart manufacturing technologies for enhanced efficiency, precision, and waste reduction in sheet and board production.

These trends underscore a pivotal moment for B2B decision-makers: partnering with manufacturers who are at the forefront of these innovations is no longer an option, but a necessity for future competitiveness.

Profiles of Leading Companies at Chinaplas

Baoding Lida Plastic Industry Co., Ltd: A Beacon of Innovation in Rigid Sheets

When discussing top-tier Chinese manufacturers of plastic sheets and PVC boards, Baoding Lida Plastic Industry Co., Ltd stands out. Recognized for its deep expertise and unwavering commitment to quality, Lida Plastic has carved a significant niche in both domestic and international markets. Their presence at Chinaplas consistently draws attention from buyers seeking reliable, high-performance rigid plastic solutions.

- • Strong Manufacturing Capacity: Baoding Lida boasts state-of-the-art production facilities, enabling them to handle large-scale orders while maintaining stringent quality controls. Their advanced machinery and optimized production lines ensure consistent output and timely delivery, crucial for global supply chains.

- • Extensive Product Customization: A key differentiator for Lida Plastic is their extensive product customization capabilities. They excel in tailoring various plastic sheets and PVC boards to meet specific client requirements for applications ranging from industrial fabrication to sophisticated display solutions. This includes precise dimensions, thicknesses, colors, and specialized surface treatments.

- • Focus on PP Rigid Sheet (Glossy Surface): A prime example of their specialized offerings is the PP rigid sheet with a glossy surface. This product is engineered for applications demanding both excellent mechanical properties and a premium aesthetic. Its glossy finish provides a superior look, making it ideal for printing, packaging, and display applications where visual impact is paramount. Lida Plastic ensures that these sheets possess high stiffness, good impact resistance, and are easily formable, catering to diverse industrial needs.

- • Competitive Cost Structure & Consistent Quality: Lida Plastic leverages its efficient production processes and supply chain management to offer highly competitive pricing without compromising on quality. Their commitment to consistent quality assurance for both domestic and international markets builds trust and long-term partnerships.

Experience the quality and versatility of PP rigid sheet (glossy surface) and other advanced materials. Learn more about Baoding Lida's offerings.

The Broader Landscape: Global & Regional Innovators

While Baoding Lida exemplifies excellence in specialized rigid sheets and boards, the global plastics stage at Chinaplas also hosts a wider array of industry giants. Companies like Amcor, Berry Global, and Huhtamaki are global leaders, primarily renowned for their expansive portfolios in flexible packaging, films, and container111s. Their innovations often trickle down to influence rigid plastic materials, pushing boundaries in areas like barrier properties, lightweighting, and sustainable composites.

However, the unique advantage of Chinese manufacturers in the plastic sheet and PVC board sector lies in their agility, advanced manufacturing capabilities, and often more competitive pricing structures for high-volume, quality products. Beyond these global behemoths, Chinaplas showcases a multitude of other regional and international plastic film and flexible packaging manufacturers, alongside specialized producers of rigid materials. These companies contribute to a vibrant ecosystem, fostering innovation across the entire plastics value chain. The show is a testament to how Chinese manufacturers, often with a deep focus on core material production, are not just participants but key drivers of innovation in specific segments like PP rigid sheet (glossy surface) and specialized PVC boards, offering quality and customization that rival global standards.

Market Outlook & Opportunities: Charting the Future of Rigid Plastics

The trajectory for plastic sheet and PVC board manufacturers is ripe with opportunities, shaped by evolving buyer demands and technological advancements. Decision-makers at Chinaplas will observe several key trends defining the market's future:

- ● Increased Demand for Specialty Materials: Buyers are increasingly seeking not just standard sheets, but specialty materials like PP rigid sheet (glossy surface) for specific aesthetic and functional needs, or PVC boards with enhanced fire retardancy, UV resistance, or specific densities for construction and industrial applications. This pushes manufacturers to invest in R&D and advanced compounding techniques.

- ● Automation and Smart Manufacturing: The plastics industry is rapidly embracing Industry 4.0. For plastic sheet and PVC board production, this means integrated automation, AI-driven process optimization, and real-time quality control. These technologies lead to higher precision, reduced waste, increased efficiency, and consistent product quality – critical for meeting global standards.

- ● Circular Economy Solutions: Sustainability remains a dominant force. Opportunities abound for manufacturers who can offer verifiable recycled content in their sheets and boards, develop materials that are easier to recycle at end-of-life, or innovate with bio-based alternatives. This aligns with global regulatory pressures and corporate sustainability goals.

- ● Digitalization of Supply Chains: From transparent sourcing to efficient logistics, digitalization is streamlining the entire supply chain, making it easier for international buyers to procure materials from Chinese manufacturers with greater confidence and reduced lead times.

These dynamics present a fertile ground for growth, particularly for manufacturers like Baoding Lida who are strategically positioned to leverage advanced technology and a deep understanding of material science to meet evolving market demands.

Buyer/Business Takeaways: Strategic Moves in Rigid Plastics Procurement

For B2B decision-makers, understanding the strategic implications of these trends is paramount. Investing in high-quality plastic sheets and PVC boards from leading Chinese manufacturers, especially those showcased at Chinaplas, makes strategic sense for several reasons:

- ✓ Cost-Effectiveness Without Compromise: Chinese manufacturers, often benefiting from economies of scale and efficient production, provide highly competitive pricing. This allows businesses to maintain healthy margins while accessing high-quality materials like PP rigid sheet (glossy surface) that meet international standards.

- ✓ Access to Advanced Customization & Innovation: Companies like Baoding Lida offer unparalleled customization, allowing buyers to source materials precisely engineered for their unique applications. This includes specialized formulations, dimensions, and surface finishes, giving businesses a distinct competitive edge.

- ✓ Reliable Supply Chain & Scalability: Leading Chinese manufacturers have robust production capacities and established logistics networks, ensuring a reliable and scalable supply chain, even for demanding international orders.

Tips for Adopting or Partnering with Chinese Manufacturers:

- • Due Diligence: Thoroughly vet potential partners. Chinaplas provides an excellent opportunity for face-to-face meetings and factory visits. Assess certifications, quality control processes, and R&D capabilities.

- • Clear Specifications: Provide detailed product specifications, especially for specialized materials like PP rigid sheet (glossy surface). This minimizes misunderstandings and ensures the final product meets expectations.

- • Focus on Long-Term Relationships: Building trust and establishing long-term partnerships with Chinese manufacturers often yields better terms, priority service, and collaborative innovation.

- • Evaluate Sustainability Efforts: Inquire about their sustainability practices, use of PCR materials, and energy-efficient production processes to align with your corporate ESG goals.

Future-Proof Strategies:

To future-proof your business in a rapidly evolving market, consider integrating suppliers who demonstrate agility in adopting new technologies, a commitment to sustainable production, and the capability to innovate collaboratively. Diversifying your supply chain to include Chinese specialists in plastic sheets and PVC boards will enhance resilience and flexibility, positioning your company for sustained success.

Conclusion: Chinaplas – A Gateway to Innovation

Chinaplas remains an indispensable event for anyone involved in the global plastics industry, serving as a critical platform for shaping the future of plastic sheet and PVC board manufacturing. From cutting-edge material science to advanced automation, the innovations showcased by leading Chinese manufacturers are setting new benchmarks for quality, sustainability, and efficiency.

As you navigate the opportunities presented by this dynamic sector, consider the expertise and advanced capabilities of companies like Baoding Lida Plastic Industry Co., Ltd. Their commitment to producing high-quality, customizable materials, including the sought-after PP rigid sheet with a glossy surface, positions them as a valuable partner for businesses seeking to elevate their product offerings and operational efficiency.

Ready to explore advanced plastic sheet solutions?

Visit Baoding Lida Plastic Industry Co., Ltd to Learn MoreDiscover how innovation in rigid plastics can drive your business forward.

-

Comprehensive Guide to HDPE Sewer Pipes: Benefits, Applications & Innovations

NewsNov.25,2025

-

Comprehensive Guide To HDPE Pipes and Fittings | Durable & Sustainable Solutions

NewsNov.24,2025

-

HDPE Culvert Pipe – Durable, Flexible & Sustainable Infrastructure Solutions

NewsNov.24,2025

-

DWC HDPE Pipe – Durable, Cost-Effective Drainage and Conduit Solutions

NewsNov.23,2025

-

HDPE Drainage Pipe – Durable and Sustainable Water Management Solutions

NewsNov.23,2025

-

Durable and Sustainable HDPE Corrugated Pipe Solutions for Modern Infrastructure

NewsNov.23,2025