Aug . 29, 2024 23:52 Back to list

pp rigid sheet

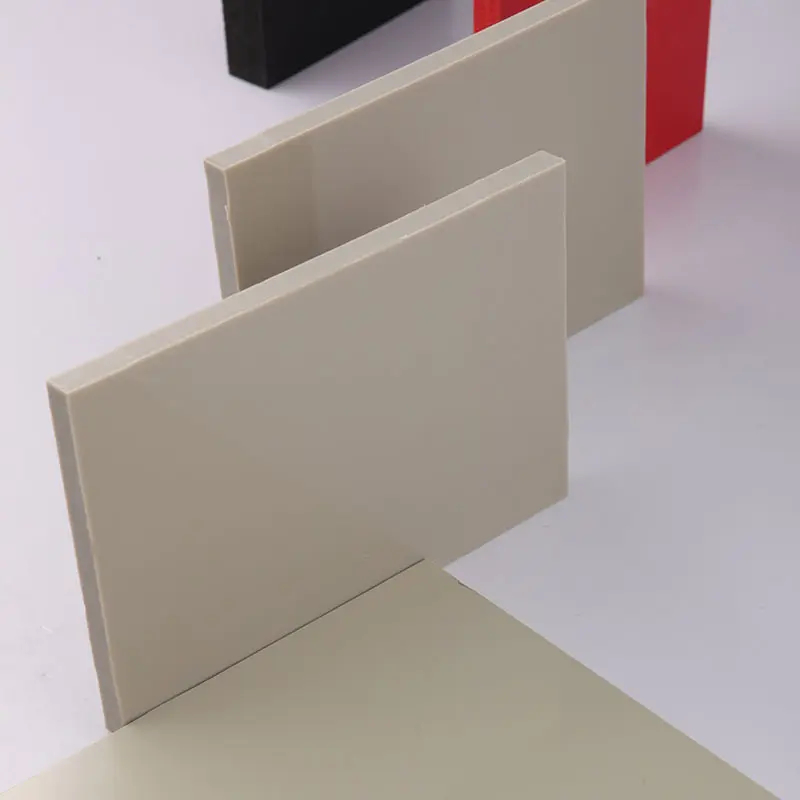

Understanding PP Rigid Sheet Applications and Benefits

Polypropylene (PP) rigid sheet is an innovative material that has gained significant attention in various industries due to its versatile properties and applications. This thermoplastic polymer is characterized by its rigidity, light weight, and excellent chemical resistance, making it an ideal choice for a wide range of applications, from packaging to industrial uses.

Composition and Properties

PP rigid sheets are manufactured from polypropylene resin, which is known for its high strength-to-weight ratio. This property not only contributes to the durability of the sheets but also reduces shipping and handling costs due to their light weight. Additionally, PP sheets offer outstanding resistance to chemicals, moisture, and UV radiation, making them suitable for outdoor applications without significant degradation over time.

The sheets can be produced in various thicknesses, colors, and finishes, allowing for customization to meet specific requirements. Their surface can be smooth or textured, enhancing their application potential in different environments. Moreover, they can be easily fabricated, welded, or printed on, which adds to their versatility in manufacturing processes.

Applications

One of the most prevalent uses of PP rigid sheets is in the packaging industry. Their durability and resistance to moisture make them an excellent choice for containers, boxes, and pallets. Businesses often utilize these sheets for manufacturing packaging materials that need to withstand various environmental conditions while protecting the contents inside.

pp rigid sheet

In the construction industry, PP sheets serve as effective solutions for temporary barriers, signage, and even as components in modular construction. Their lightweight nature, coupled with their strength, provides a logistical advantage during projects, allowing for easier transportation and installation.

Furthermore, PP rigid sheets are commonly used in the medical field for a variety of applications, including trays, boxes, and dividers for surgical instruments. The sheets can be easily sterilized, ensuring that they meet strict hygiene standards critical in healthcare settings.

Another significant application can be found in the automotive industry, where PP sheets are used in interior panels, dashboards, and other components. Their ability to withstand high temperatures and resist wear makes them a suitable choice for automotive applications where durability is paramount.

Environmental Considerations

As industries move towards sustainability, the recyclability of PP rigid sheets becomes a notable advantage. Polypropylene can be recovered and recycled, which aligns with the growing emphasis on reducing plastic waste. Manufacturers are increasingly prioritizing environmentally friendly practices, making PP rigid sheets a compelling choice for companies looking to enhance their sustainability profiles.

Conclusion

PP rigid sheets are a remarkable material that combines strength, versatility, and eco-friendliness, making them suitable for a wide range of applications across various industries. With ongoing advancements in technology and manufacturing processes, the uses for PP sheets continue to expand, solidifying their place as a preferred material in both traditional and innovative applications. As businesses increasingly seek durable and sustainable materials, the demand for PP rigid sheets is likely to grow, paving the way for new opportunities in the marketplace.

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025