Dec . 04, 2024 07:23 Back to list

Understanding Applications and Benefits of PE Pipe Fittings in Modern Plumbing Systems

Understanding PE Pipe Fittings A Comprehensive Guide

Polyethylene (PE) pipe fittings are rapidly becoming essential components in various industries, particularly in water management and irrigation systems. The evolving technology of PE products has revolutionized the way we think about plumbing and the distribution of fluids. This article delves into what PE pipe fittings are, their applications, benefits, and considerations.

What are PE Pipe Fittings?

PE pipe fittings are connection components made from polyethylene, a thermoplastic polymer. These fittings are used to join different lengths of PE pipes or to change the direction of flow within a piping system. Common types of PE fittings include elbows, tees, reducers, couplings, and flanges. Their designs allow for efficient assembly, maintenance, and operation of piping systems.

Applications of PE Pipe Fittings

PE pipe fittings are widely used in various applications, including

1. Water Supply and Distribution They are used in municipal water supply systems, where they ensure the safe and efficient transport of potable water. 2. Irrigation The agriculture sector utilizes PE fittings for agricultural irrigation systems, allowing efficient water delivery to crops with minimal wastage. 3. Gas Distribution PE pipe fittings are also employed in natural gas distribution networks due to their resistance to corrosion and ability to withstand varying pressures.

4. Wastewater Management Municipal wastewater systems often use PE fittings for their durability and resistance to chemicals present in wastewater.

Benefits of PE Pipe Fittings

PE pipe fittings offer numerous advantages over traditional materials such as metal or PVC. Some key benefits include

1. Durability PE is highly resistant to rust, corrosion, and chemical abrasion, ensuring a longer lifespan and reduced need for maintenance.

2. Flexibility The flexibility of PE pipes allows for easier installation, especially in areas with challenging terrain. This adaptability minimizes the risk of damage during installation and over time.

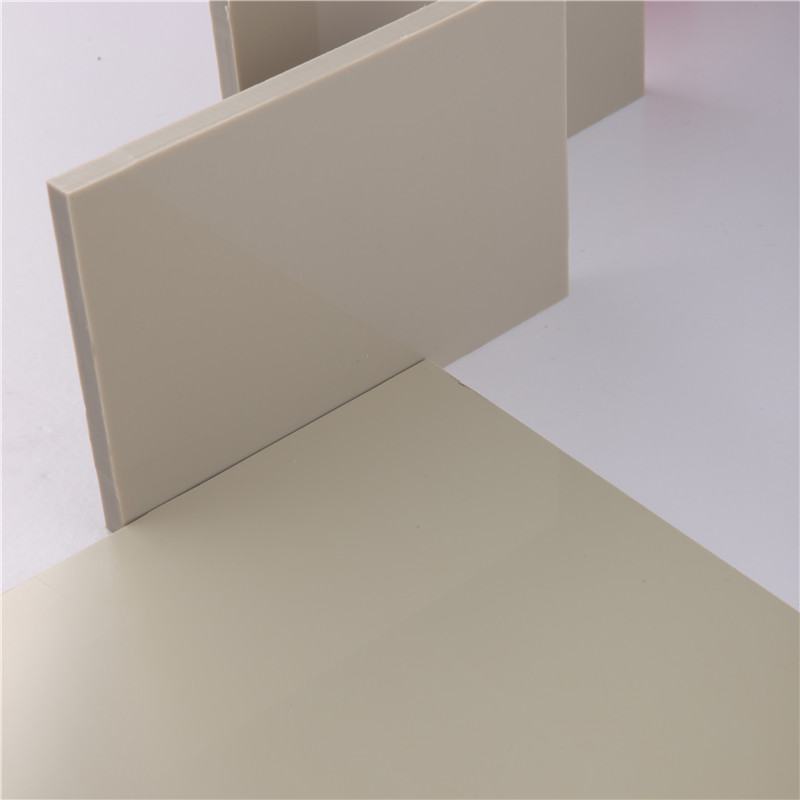

pe pipe fittings

3. Lightweight Compared to metal fittings, PE fittings are lighter, making transportation and handling easier, as well as reducing the overall cost of installation.

4. Leak-Free Joints Advanced welding techniques such as butt fusion and socket fusion create strong, leak-proof joints, reducing the risk of failure in high-pressure applications.

5. Cost-Effectiveness While the initial cost may be comparable to other materials, the longevity, reduced maintenance requirements, and lower installation costs make PE fittings a cost-effective choice in the long run.

Considerations When Choosing PE Pipe Fittings

When selecting PE pipe fittings for a project, several factors should be carefully considered

1. Sizing and Standards Ensure that the fittings match the pipe's dimensions and comply with local regulatory standards. The correct sizing will prevent disruptions in flow and pressure.

2. Chemical Compatibility Different grades of PE may offer varying resistance to chemicals. Ensure the selected fittings are suitable for the specific fluids being transported.

3. Temperature Range PE materials may not perform optimally at extreme temperatures. It is essential to select fittings that can withstand the environmental conditions they will be exposed to.

4. Installation Requirements Depending on the installation environment, choose fittings that are easy to install and maintain.

5. Manufacturer Reputation Always opt for products from reputable manufacturers to ensure quality and reliability.

Conclusion

PE pipe fittings are integral to modern piping systems, providing versatile, durable, and cost-effective solutions for a wide range of applications. As industries continue to evolve, the demand for high-quality PE fittings will only increase, solidifying their place in the future of fluid transportation. Understanding the products available, their benefits, and their applications can help ensure that you make informed choices for your plumbing and infrastructure needs.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025