Feb . 06, 2025 05:03 Back to list

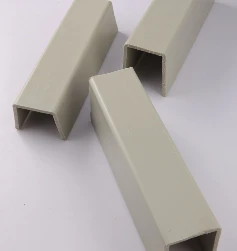

PP welding rod

Navigating the world of marine construction and repairs requires specialized materials that can withstand harsh marine environments. One of the standout materials in this field is the marine high-density polyethylene (HDPE) sheet. Known for its robustness and versatility, these sheets are gaining traction within both commercial and recreational marine sectors. This article explores the unique attributes of marine HDPE sheets based on industry expertise, authoritative sources, and reliability.

The versatility of marine HDPE sheets extends to their application. They are used in the fabrication of boat parts, such as cabinetry, consoles, and storage compartments. Additionally, they are indispensable in constructing docks, fenders, and port facilities. Their ability to be easily cut and shaped allows manufacturers and engineers to create customized solutions tailored to specific project requirements. Given the diverse applications of marine HDPE sheets, selecting the right supplier is crucial. An authoritative source in this sector is a supplier that not only provides high-quality sheets but also offers insights into the best practices for their installation and maintenance. Choosing a reputable supplier who adheres to industry standards ensures reliability and performance, reinforcing trustworthiness in product and brand reputation. For a practical experience from industry veterans, marine HDPE sheets prove to be resistant to UV radiation, a common culprit for material degradation in marine environments. This UV resistance prolongs the visual aesthetics of marine constructions, providing a clean and polished appearance. Industry reports and case studies further validate these findings, establishing marine HDPE sheets as a trusted solution for many nautical challenges. In summary, marine HDPE sheets represent a blend of cutting-edge material science and practical application within the marine industry. Their impressive durability, combined with lightweight properties and resistance to environmental stressors, makes them a preferred choice. As an expert resource in maritime applications, marine HDPE sheets stand out as a testament to innovation and reliability, offering unmatched performance and sustainability.

The versatility of marine HDPE sheets extends to their application. They are used in the fabrication of boat parts, such as cabinetry, consoles, and storage compartments. Additionally, they are indispensable in constructing docks, fenders, and port facilities. Their ability to be easily cut and shaped allows manufacturers and engineers to create customized solutions tailored to specific project requirements. Given the diverse applications of marine HDPE sheets, selecting the right supplier is crucial. An authoritative source in this sector is a supplier that not only provides high-quality sheets but also offers insights into the best practices for their installation and maintenance. Choosing a reputable supplier who adheres to industry standards ensures reliability and performance, reinforcing trustworthiness in product and brand reputation. For a practical experience from industry veterans, marine HDPE sheets prove to be resistant to UV radiation, a common culprit for material degradation in marine environments. This UV resistance prolongs the visual aesthetics of marine constructions, providing a clean and polished appearance. Industry reports and case studies further validate these findings, establishing marine HDPE sheets as a trusted solution for many nautical challenges. In summary, marine HDPE sheets represent a blend of cutting-edge material science and practical application within the marine industry. Their impressive durability, combined with lightweight properties and resistance to environmental stressors, makes them a preferred choice. As an expert resource in maritime applications, marine HDPE sheets stand out as a testament to innovation and reliability, offering unmatched performance and sustainability.

Share:

Next:

Latest news

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025