Jul . 28, 2024 15:00 Back to list

Innovative Techniques for Using PVC Plastic Welding Rods in Various Applications and Projects

Understanding PVC Plastic Welding Rods Applications and Benefits

PVC (Polyvinyl Chloride) plastic welding rods are essential tools in various industries, particularly in manufacturing, construction, and repair of plastic structures. These rods are made from the same material as the PVC components they are used to join, ensuring a strong and durable bond. In this article, we will explore the properties, applications, and advantages of using PVC plastic welding rods.

Properties of PVC Plastic Welding Rods

PVC plastic welding rods are designed to melt and fuse with the base PVC material when heat is applied. The rods usually come in different diameters and colors, which allows for versatility depending on the specific project requirements. The melting point of PVC is around 100-260°C (212-500°F), which means that these rods can be easily melted using heat guns or welding machines.

These rods exhibit several desirable properties, including chemical resistance, flexibility, and durability. This makes them suitable for a variety of uses, as they can withstand harsh environmental conditions without degrading. Furthermore, PVC welding rods are generally resistant to water and corrosion, making them ideal for projects that involve exposure to moisture or chemicals.

Applications of PVC Plastic Welding Rods

One of the primary applications of PVC plastic welding rods is in pipe and fittings installation and repair. PVC pipes are commonly used in plumbing and drainage systems, and welding rods are used to repair any damaged sections or to create new connections. By using welding rods, plumbers can ensure a watertight seal that prevents leaks and maintains the integrity of the overall system.

Another significant application is in the fabrication of signs and displays. PVC sheets are often utilized for commercial signs, and welding rods can securely bond these sheets together or attach them to frames. The aesthetic flexibility of PVC, combined with the various colors of welding rods, allows for creative and visually appealing designs.

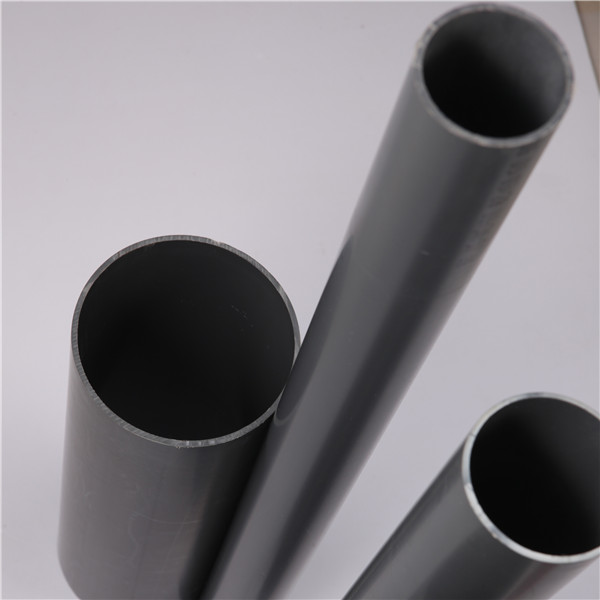

pvc plastic welding rod

In the manufacturing sector, PVC plastic welding rods are employed in the production of various components, ranging from automotive parts to household items. They provide an efficient means of assembling and repairing plastic parts without the need for additional fasteners or adhesives, streamlining the manufacturing process.

Benefits of Using PVC Plastic Welding Rods

The use of PVC plastic welding rods offers numerous advantages. First and foremost, they provide strong and reliable joints that are typically stronger than the original material. This ensures that the repaired or joined parts can withstand stress and strain during use, thereby extending their lifespan.

Additionally, using PVC welding rods is generally a cost-effective solution for repairs and assembly. Instead of replacing entire components, manufacturers and workers can make targeted repairs using welding rods, which saves both time and money. The ease of use also contributes to faster project completion, enhancing productivity.

Moreover, the availability of PVC welding rods in various sizes and colors allows for customization, making them versatile for a wide range of applications. Professionals and DIY enthusiasts alike can choose the appropriate rod for their specific needs, ensuring aesthetic and functional requirements are met.

Conclusion

In summary, PVC plastic welding rods are a vital resource in many industries that rely on PVC materials. Their ability to provide strong, reliable bonds, combined with cost-effectiveness and ease of use, makes them a preferred choice for various applications. Whether in plumbing, manufacturing, or signage, understanding how to utilize PVC welding rods effectively can lead to significant benefits in project execution and durability.

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025

-

Durable HDPE Sheet | Versatile & Impact-Resistant Plastic

NewsAug.13,2025

-

Premium PVC Soft Sheets: Clear, Flexible & Durable

NewsAug.12,2025

-

Premium PVC Round Rods: Durable, Chemical Resistant, Easy to Machine

NewsAug.11,2025