Jul . 25, 2024 04:33 Back to list

Innovative Techniques and Applications for Round Percentage Welding Rods in Modern Fabrication Practices

Understanding Round PP Welding Rods Applications, Benefits, and Techniques

Round PP (Polypropylene) welding rods are an essential component in the fabrication and repair of plastic materials. These rods are specifically designed for use in welding processes involving polypropylene, a thermoplastic polymer known for its excellent chemical resistance, durability, and low-density properties. In this article, we will explore the various applications, benefits, and techniques associated with round PP welding rods.

Applications of Round PP Welding Rods

Round PP welding rods are widely utilized across different industries. One of the primary applications is in the construction of tanks, containers, and pipes that require chemical resistance, such as in the chemical processing and wastewater treatment industries. These rods are also used in the production of automotive components, medical devices, and consumer products, where the need for lightweight yet strong materials is critical.

In addition to industrial applications, round PP welding rods are frequently employed in DIY projects and home repairs. Craftsmen and hobbyists use these rods to repair or fabricate items made from polypropylene, such as outdoor furniture, storage bins, and plastic enclosures.

Benefits of Using Round PP Welding Rods

There are several advantages to using round PP welding rods. Firstly, polypropylene exhibits an excellent balance of strength and weight, making it a preferred choice in scenarios where lightweight materials are advantageous. The chemical resistance of PP ensures that products made with these rods can withstand exposure to various substances without degrading.

Another significant benefit is the ease of welding polypropylene. Round PP welding rods can be quickly and efficiently fused to existing polypropylene structures, making repairs and modifications straightforward. The welding process also results in strong joints that maintain the integrity of the original material.

round pp welding rod

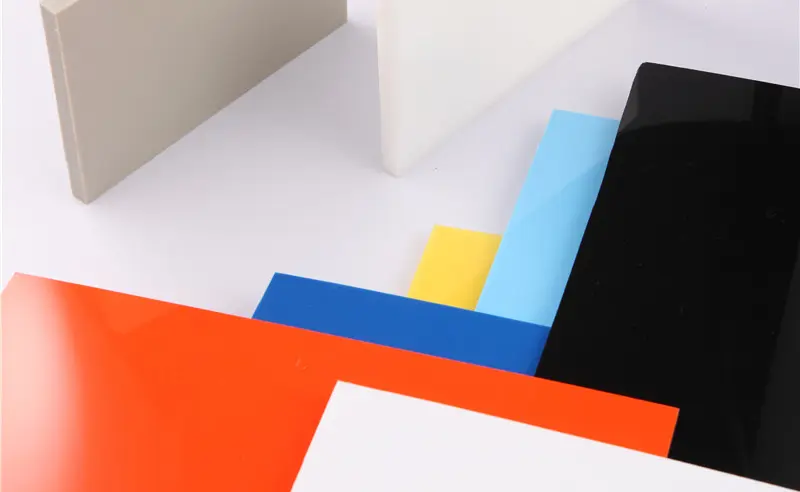

Moreover, round PP welding rods are available in various diameters and colors, allowing for customization based on specific project requirements. This versatility further enhances their appeal in both industrial settings and DIY applications.

Welding Techniques for Round PP Rods

Welding polypropylene using round PP rods typically involves techniques such as hot air welding, extrusion welding, and butt welding. Each method has its advantages and is suited for different types of applications.

1. Hot Air Welding This technique involves the use of a hot air tool to preheat the polypropylene surfaces before introducing the welding rod. The operator feeds the round PP rod into the joint while applying heat, allowing the rod to melt and bond with the existing material. This method is widely used for repairing and fabricating larger components.

2. Extrusion Welding In this process, a welding machine extrudes the round PP rod along the joint to create a continuous bead. This technique is particularly efficient for welding long seams, such as those found in tanks or large containers. It provides a consistent weld and can be automated for increased efficiency.

3. Butt Welding This method involves aligning two pieces of polypropylene and applying heat to their edges using a specialized machine. Once the edges are melted, they are pressed together, forming a strong bond. Butt welding is often used for pipe fittings and joints.

Conclusion

Round PP welding rods are invaluable in a variety of applications, from industrial manufacturing to home repairs. Their unique properties, ease of use, and compatibility with multiple welding techniques make them a popular choice for anyone working with polypropylene. As industries continue to advance, the importance of effective and efficient welding methods using round PP rods will only grow, driving innovation and application in this essential area of material fabrication.

-

Durable PP Rigid Sheet: Lightweight, Chemical Resistant Solutions

NewsAug.21,2025

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025