Aug . 18, 2024 09:58 Back to list

High-Density Polyethylene Pipe Fittings for Durable and Efficient Plumbing Solutions

Understanding HDPE Pipe Fittings Importance and Applications

High-Density Polyethylene (HDPE) pipe fittings play a crucial role in a variety of piping systems across multiple industries. Made from thermoplastic materials, HDPE is known for its high strength-to-density ratio, resistance to corrosion, and ease of installation. This article explores the significance of HDPE pipe fittings, their applications, and the reasons behind their growing popularity.

What are HDPE Pipe Fittings?

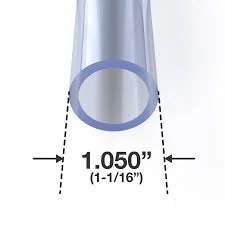

HDPE pipe fittings are components used to connect sections of HDPE pipes. These fittings can come in various shapes, such as elbows, tees, reducers, flanges, and couplings. The primary function of these fittings is to facilitate the flow of liquids and gases in a piping system while ensuring structural integrity and leak-proof connections. Additionally, HDPE fittings are available in different diameters and pressure ratings to suit various applications.

Advantages of HDPE Pipe Fittings

1. Durability One of the significant benefits of HDPE fittings is their durability. They can withstand harsh environmental conditions, including extreme temperatures and high chemical concentrations, without degrading. This durability translates into longer service life and less frequent replacements, reducing overall maintenance costs.

2. Corrosion Resistance Unlike traditional metal fittings, HDPE pipe fittings do not corrode. This property makes them ideal for applications involving aggressive chemicals, wastewater, and other corrosive materials. The resistance to corrosion also ensures that the quality of transported fluids remains uncontaminated.

3. Lightweight and Easy to Install HDPE fittings are significantly lighter than their metal counterparts, making them easier to handle during transportation and installation. This characteristic allows for quicker assembly and less labor-intensive installation processes.

4. Flexibility HDPE materials provide a level of flexibility, allowing the fittings to absorb stress without cracking. This flexibility is particularly advantageous in applications where ground movement might occur, such as in areas prone to earthquakes.

hdpe pipe fittings

5. Environmental Impact HDPE is a recyclable material, making it an environmentally friendly choice. Manufacturers of HDPE fittings often utilize recycled materials in their production processes, further reducing the carbon footprint associated with piping installations.

Applications of HDPE Pipe Fittings

HDPE pipe fittings are used in a myriad of applications across different sectors

- Water Supply Systems These fittings are commonly used in municipal water supply systems due to their ability to maintain the purity of drinking water and resist corrosion. - Wastewater Management Given their resistance to chemicals and corrosion, HDPE pipe fittings are extensively utilized in sewage and wastewater treatment facilities.

- Irrigation Systems In agricultural applications, HDPE fittings are favored for irrigation networks, ensuring the efficient and reliable distribution of water.

- Industrial Applications Many industries, including chemical processing, oil and gas, and food processing, utilize HDPE fittings for transporting various substances safely.

- Mining Operations HDPE pipe fittings are used in mining for slurry transportation, given their durability and resistance to wear and tear.

Conclusion

In summary, HDPE pipe fittings are essential components in modern piping systems due to their unparalleled durability, corrosion resistance, and ease of installation. As industries increasingly prioritize sustainability and efficiency, the demand for HDPE fittings is expected to rise. Their versatility allows for widespread application across water supply, wastewater management, agriculture, and various industrial processes. With ongoing advancements in material technology, HDPE pipe fittings will continue to play a pivotal role in shaping the future of piping solutions.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025