Jun . 24, 2024 02:18 Back to list

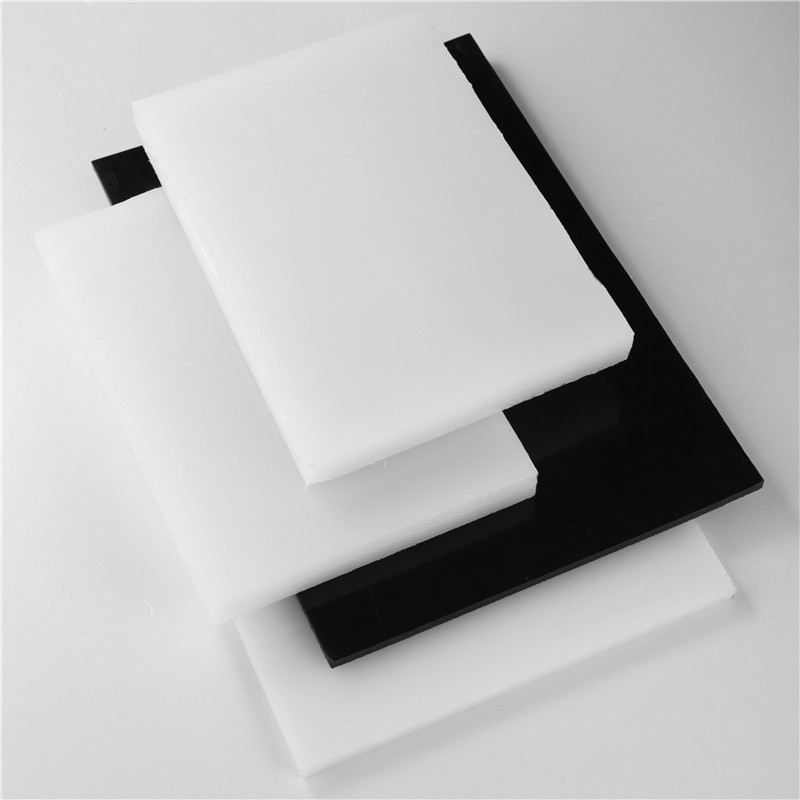

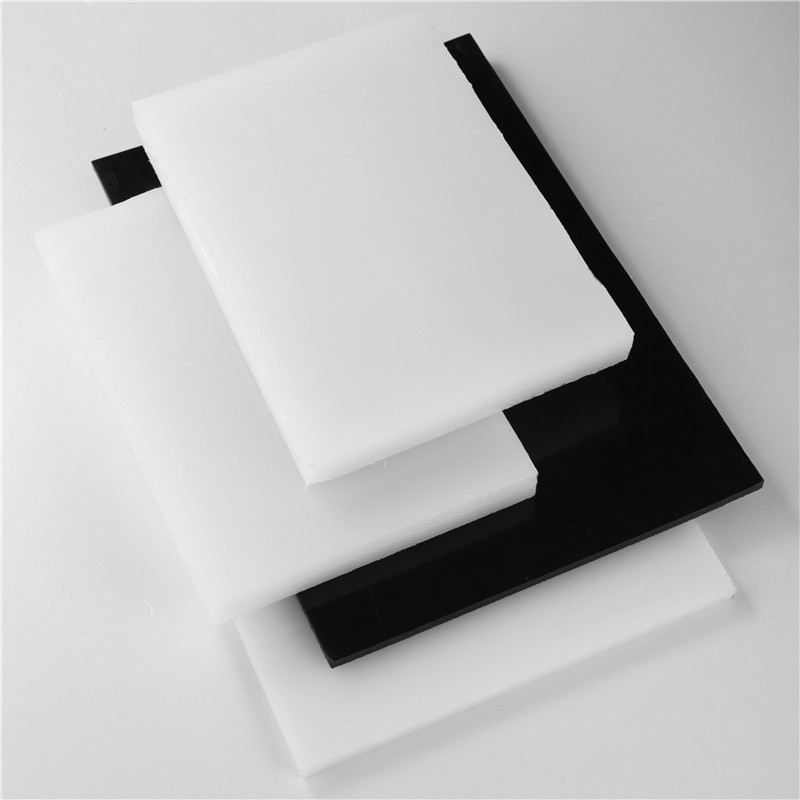

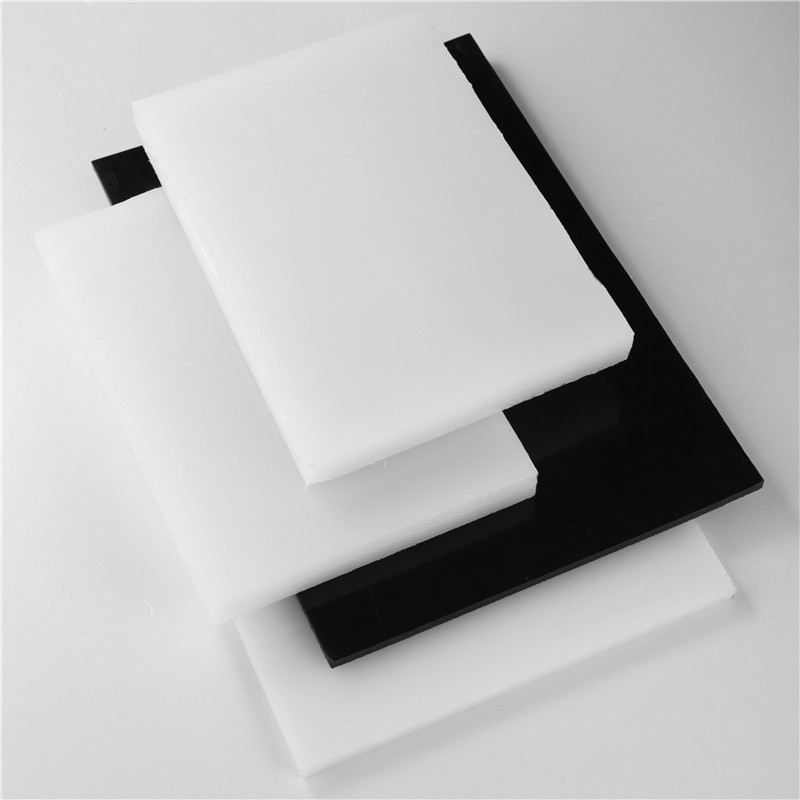

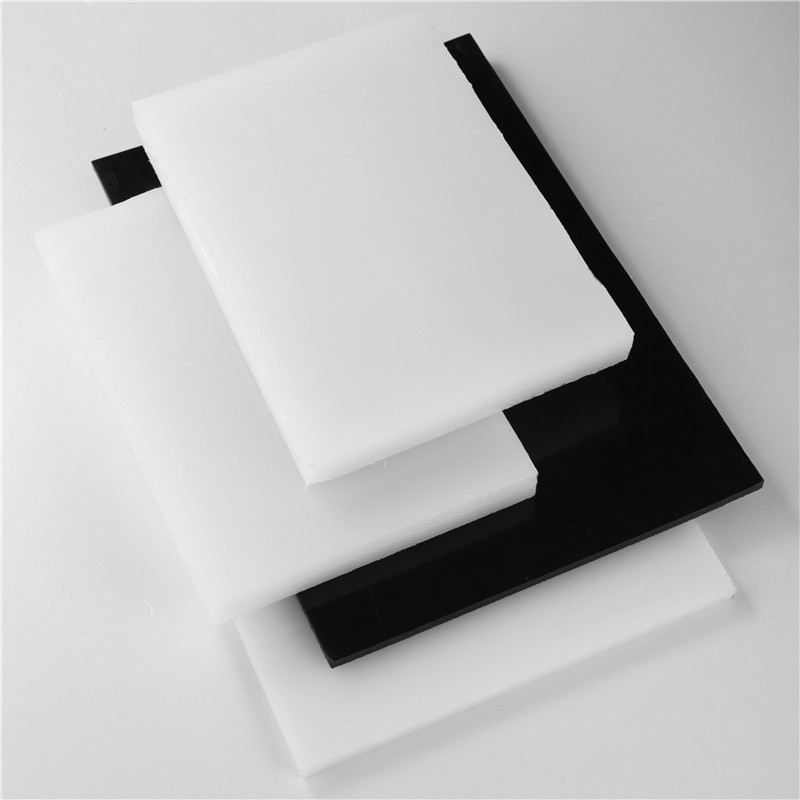

High-Density Polyethylene (HDPE) 4mm Thick Sheet

Understanding the 4mm HDPE Sheet A Comprehensive Overview

High-Density Polyethylene (HDPE) sheets have become an indispensable material in various industries due to their exceptional durability and versatility. One variant that has gained significant attention is the 4mm HDPE sheet, which offers a unique blend of properties that make it suitable for numerous applications.

HDPE, a thermoplastic polymer, is known for its high strength-to-density ratio, making it an ideal choice for situations where both toughness and lightness are required. The 4mm thickness adds another layer of resilience to this already robust material, making it apt for demanding conditions. This particular thickness falls between the more slender sheets and the thicker ones, providing a balance between flexibility and rigidity.

The 4mm HDPE sheet exhibits excellent chemical resistance, withstanding exposure to a wide range of corrosive substances. It also displays outstanding weather resistance, making it perfect for outdoor applications where it can endure harsh environmental conditions. Its UV stabilizers further enhance its ability to resist degradation from prolonged sunlight exposure.

In terms of mechanical properties, the 4mm HDPE sheet boasts impressive impact resistance, even at low temperatures. It is also highly resistant to scratching and denting, ensuring its longevity in high-traffic or high-stress environments. Its non-porous surface makes it easy to clean and maintain, adding to its hygiene benefits in sectors like food processing and medical equipment manufacturing.

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength 4mm hdpe sheet. Its weldability and machinability make it a favorite among engineers and fabricators who seek a material that can be customized to meet specific design requirements.

Applications of 4mm HDPE sheets span across diverse industries. In construction, they are used as liners for water tanks, sewage systems, and foundations due to their resistance to moisture and chemicals. In agriculture, they serve as protective covers for crops and livestock shelters. In manufacturing, they are employed in the production of industrial containers, tanks, and machinery parts. Additionally, they find use in sports equipment, playground surfaces, and even as protective gear in the sports industry.

In conclusion, the 4mm HDPE sheet is a versatile material that combines the inherent strengths of HDPE with a thickness that caters to a broad spectrum of uses. Its durability, chemical resistance, and ease of fabrication make it a go-to option for engineers, designers, and manufacturers seeking a reliable and adaptable material. As technology advances and sustainability becomes a priority, the role of 4mm HDPE sheets in shaping the future of various industries is expected to grow even more prominent.

4mm hdpe sheet. Its weldability and machinability make it a favorite among engineers and fabricators who seek a material that can be customized to meet specific design requirements.

Applications of 4mm HDPE sheets span across diverse industries. In construction, they are used as liners for water tanks, sewage systems, and foundations due to their resistance to moisture and chemicals. In agriculture, they serve as protective covers for crops and livestock shelters. In manufacturing, they are employed in the production of industrial containers, tanks, and machinery parts. Additionally, they find use in sports equipment, playground surfaces, and even as protective gear in the sports industry.

In conclusion, the 4mm HDPE sheet is a versatile material that combines the inherent strengths of HDPE with a thickness that caters to a broad spectrum of uses. Its durability, chemical resistance, and ease of fabrication make it a go-to option for engineers, designers, and manufacturers seeking a reliable and adaptable material. As technology advances and sustainability becomes a priority, the role of 4mm HDPE sheets in shaping the future of various industries is expected to grow even more prominent.

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength

Moreover, the 4mm HDPE sheet is easily processed and fabricated, allowing it to be shaped and molded into various forms without losing its inherent strength 4mm hdpe sheet. Its weldability and machinability make it a favorite among engineers and fabricators who seek a material that can be customized to meet specific design requirements.

Applications of 4mm HDPE sheets span across diverse industries. In construction, they are used as liners for water tanks, sewage systems, and foundations due to their resistance to moisture and chemicals. In agriculture, they serve as protective covers for crops and livestock shelters. In manufacturing, they are employed in the production of industrial containers, tanks, and machinery parts. Additionally, they find use in sports equipment, playground surfaces, and even as protective gear in the sports industry.

In conclusion, the 4mm HDPE sheet is a versatile material that combines the inherent strengths of HDPE with a thickness that caters to a broad spectrum of uses. Its durability, chemical resistance, and ease of fabrication make it a go-to option for engineers, designers, and manufacturers seeking a reliable and adaptable material. As technology advances and sustainability becomes a priority, the role of 4mm HDPE sheets in shaping the future of various industries is expected to grow even more prominent.

4mm hdpe sheet. Its weldability and machinability make it a favorite among engineers and fabricators who seek a material that can be customized to meet specific design requirements.

Applications of 4mm HDPE sheets span across diverse industries. In construction, they are used as liners for water tanks, sewage systems, and foundations due to their resistance to moisture and chemicals. In agriculture, they serve as protective covers for crops and livestock shelters. In manufacturing, they are employed in the production of industrial containers, tanks, and machinery parts. Additionally, they find use in sports equipment, playground surfaces, and even as protective gear in the sports industry.

In conclusion, the 4mm HDPE sheet is a versatile material that combines the inherent strengths of HDPE with a thickness that caters to a broad spectrum of uses. Its durability, chemical resistance, and ease of fabrication make it a go-to option for engineers, designers, and manufacturers seeking a reliable and adaptable material. As technology advances and sustainability becomes a priority, the role of 4mm HDPE sheets in shaping the future of various industries is expected to grow even more prominent. Share:

Latest news

-

PVC Grey Sheet for Extraction: Chemical Resistant & Durable

NewsAug.19,2025

-

Durable PVC Pipe Fittings for Plumbing & Irrigation Needs

NewsAug.18,2025

-

HDPE Steel Belt Reinforced Spiral Corrugated Pipe | High Strength

NewsAug.17,2025

-

HDPE Pipe Fittings: Durable, Leak-Proof Solutions

NewsAug.16,2025

-

Premium CPVC Sheet: High-Temp & Chemical Resistant Solutions

NewsAug.15,2025

-

Durable PPR Pipe for Hot & Cold Water Systems - Easy Install

NewsAug.14,2025