Aug . 05, 2024 03:06 Back to list

High-Density Polyethylene Double-Wall Corrugated Pipe for Efficient Drainage Solutions and Applications

Exploring HDPE Double Wall Corrugated Pipe A Versatile Solution for Modern Infrastructure

High-density polyethylene (HDPE) double wall corrugated pipes have emerged as a vital component in modern infrastructure projects, thanks to their strength, durability, and versatility. These pipes are widely used in various applications, including drainage systems, stormwater management, and sewage disposal. This article delves into the features, advantages, and applications of HDPE double wall corrugated pipes, shedding light on why they have become a go-to solution in the construction industry.

Understanding HDPE Double Wall Corrugated Pipes

HDPE double wall corrugated pipes consist of two layers an inner wall that provides structural integrity and an outer corrugated wall that enhances strength and flexibility. The corrugated design allows these pipes to withstand external loads and pressures, making them suitable for both surface and subsurface applications. The lightweight nature of HDPE makes installation easier and reduces transportation costs, thereby enhancing the overall efficiency of construction projects.

Advantages of HDPE Double Wall Corrugated Pipes

1. Durability One of the most compelling features of HDPE is its resistance to corrosion, chemicals, and extreme temperatures. Unlike traditional materials, such as concrete or PVC, HDPE does not degrade over time, ensuring a long service life and reducing the need for frequent replacements.

2. Flexibility The flexibility of HDPE allows it to be installed in challenging environments. Its ability to bend without breaking makes it ideal for various applications, including areas with shifting soil or complex layouts.

3. Lightweight HDPE double wall corrugated pipes are significantly lighter than their concrete counterparts. This contributes to lower shipping and handling costs and allows for easier installation, reducing labor costs and project timelines.

hdpe double wall corrugated pipe

4. Hydraulic Performance The smooth inner layer of HDPE pipes facilitates efficient water flow, reducing friction losses and enhancing drainage capabilities. This property is especially important in stormwater management systems, where effective water removal is crucial.

5. Environmentally Friendly HDPE is a recyclable material, making it an environmentally responsible choice for infrastructure projects. Its longevity means that less waste is generated in the long run, contributing to sustainable development.

Applications of HDPE Double Wall Corrugated Pipes

The versatility of HDPE double wall corrugated pipes has made them suitable for a wide range of applications. In civil engineering projects, they are commonly used in drainage systems to manage stormwater runoff effectively. The pipes are also employed in agricultural applications for irrigation systems and agricultural drainage, helping to optimize crop production.

Furthermore, they play a critical role in sewage disposal systems, where their strength and resistance to chemical damage ensure safe and efficient transport of wastewater. In underground utility installations, HDPE pipes are used for telecommunications and electrical conduits, providing protection against external pressures while maintaining flexibility.

Conclusion

HDPE double wall corrugated pipes represent a significant advancement in pipe technology, offering numerous benefits for a variety of applications. Their durability, lightweight nature, and superior hydraulic performance make them essential in modern infrastructure projects. As environmental concerns continue to grow, the adoption of recyclable materials like HDPE also supports sustainable construction practices. As the demand for effective drainage and sewage solutions increases, HDPE double wall corrugated pipes are set to play an even more prominent role in shaping the infrastructure of our future.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

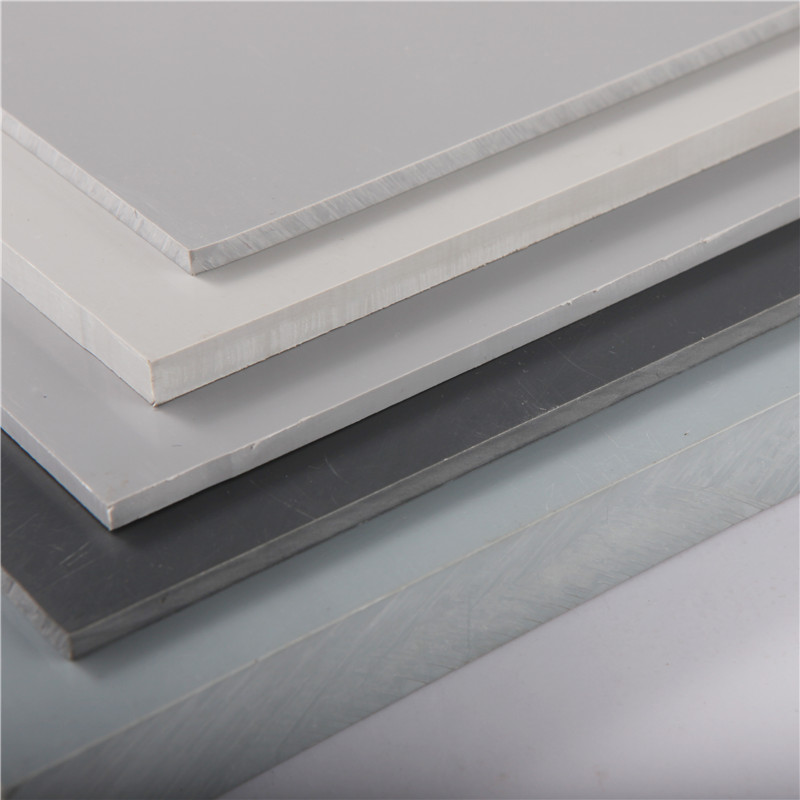

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025