Nov . 17, 2024 09:38 Back to list

Understanding HDPE Sheet Dimensions and Their Common Applications

Understanding HDPE Sheet Sizes A Comprehensive Guide

High-Density Polyethylene (HDPE) sheets have gained popularity across various industries due to their excellent durability, low moisture absorption, and resistance to a wide range of chemicals. This versatile material is utilized in applications such as packaging, construction, landscaping, and manufacturing, but one crucial aspect that often raises questions among users is the size of HDPE sheets. Understanding the standard sizes, custom options, and the best practices for selecting the right dimensions can help maximize the benefits of this material.

Standard Sizes of HDPE Sheets

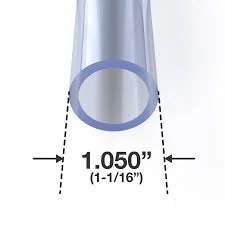

HDPE sheets are available in a variety of standard sizes, typically measured in thickness, width, and length. Common thicknesses range from 1/16 inch (1.6 mm) to 1 inch (25.4 mm), catering to different needs based on the application. The width and length of sheets can also differ, but standard dimensions often include 48 inches (1220 mm) by 96 inches (2440 mm) or 60 inches (1524 mm) by 120 inches (3048 mm). For industries that require larger sheets, there are options that can exceed these dimensions.

It's important to consult with suppliers to determine the availability of specific sizes, as this can vary by manufacturer or region. When planning a project, ordering the correct sheet size is essential to minimize waste and ensure cost-effectiveness.

Customizing HDPE Sheet Sizes

While standard sizes are widely available, many manufacturers also offer custom sizes to meet the specific requirements of a project. Customization might be necessary for unique applications, tighter spaces, or intricate designs where standard dimensions may not suffice. Custom-cut HDPE sheets allow for greater flexibility and can be tailored to fit specific project dimensions precisely.

When ordering custom sizes, it's crucial to provide accurate measurements and specifications to avoid any delays or issues with fit. Working closely with suppliers ensures that you receive the right product for your needs.

hdpe sheet sizes

Factors to Consider When Choosing HDPE Sheet Sizes

1. Application Requirements Different applications may demand specific HDPE sheet sizes. For example, construction projects might need larger sheets to cover expansive areas, while smaller sheets could suffice for household tasks.

2. Workability The size and thickness of the sheets can affect how easily they can be manipulated and installed. Thicker sheets may require more effort and specialized tools for cutting and shaping.

3. Transportation and Handling Consider the logistics of transporting larger sheets. If you're dealing with significant dimensions, ensure you have the equipment and manpower necessary to move them safely.

4. Cost Implications Larger sheets can sometimes be more economical, as they reduce waste and the need for additional seams during assembly. However, ensure that the additional cost of a larger sheet offsets any savings from reduced waste.

5. Local Regulations In some cases, local building codes or regulations may dictate specific material specifications, including sheet sizes for certain types of construction or manufacturing applications.

Conclusion

HDPE sheets are a fantastic resource in a wide range of industries due to their strength, versatility, and resistance to various environmental factors. Understanding the standard sizes and customization options available is essential for effectively utilizing this material. By considering factors such as application requirements, workability, transport logistics, and cost, you can make informed decisions when selecting the appropriate HDPE sheet sizes for your specific needs. Ultimately, choosing the right size will not only enhance project efficiency but will also contribute to successful project outcomes. Whether working on a large construction site or a small DIY project, understanding HDPE sheet sizes is key to effective material use and long-lasting results.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025