Sep . 29, 2024 05:18 Back to list

Understanding the Density of HDPE Sheets for Various Applications

Understanding HDPE Sheet Density Properties and Applications

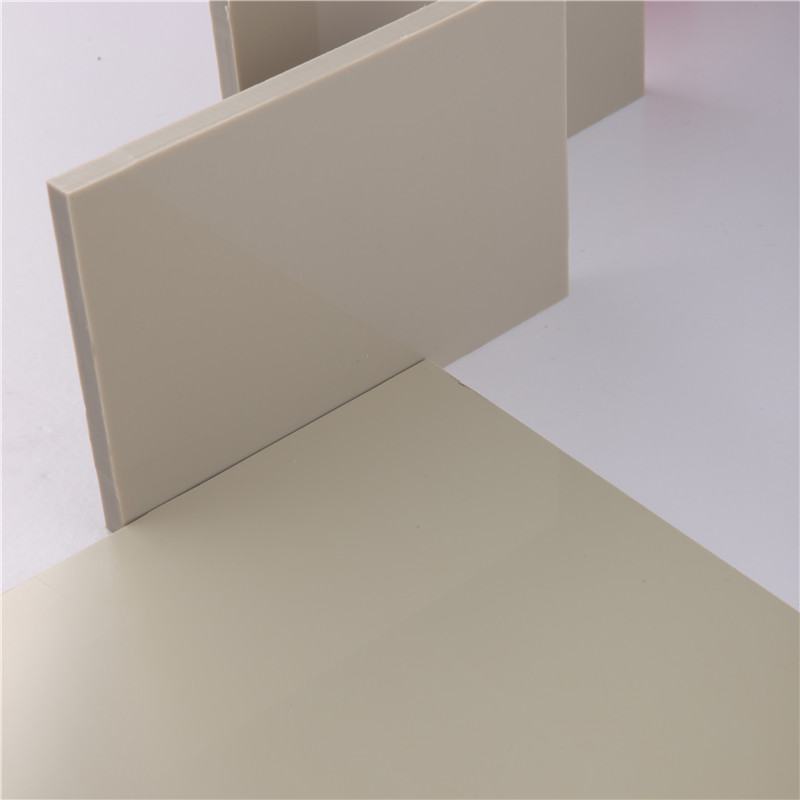

High-Density Polyethylene (HDPE) is a common thermoplastic polymer known for its high strength-to-density ratio. When considering HDPE sheets, the density plays a pivotal role in determining their suitability for various applications. Typically, HDPE sheets have a density range of 0.93 to 0.97 grams per cubic centimeter. This characteristic contributes to the material’s strength, durability, and resistance to both impact and environmental stressors.

Understanding HDPE Sheet Density Properties and Applications

The density of HDPE sheets also affects their thermal and electrical properties. For instance, materials with lower density typically exhibit better insulation capabilities, making HDPE sheets an excellent choice for electric and electronic applications. Additionally, HDPE has a high melting point, usually around 130 to 135 degrees Celsius, which adds to its appeal in high-temperature applications, such as hot-water tanks.

hdpe sheet density

Another noteworthy property of HDPE is its recyclability. Given the growing emphasis on sustainability, understanding the density of HDPE sheets becomes even more relevant. The recycling process typically involves shredding the material, which is then melted and remolded, maintaining the integrity of the properties while reducing waste. This makes HDPE an attractive choice for environmentally conscious consumers and businesses.

In terms of applications, HDPE sheets are extensively utilized in various sectors. In construction, they may be used for geomembranes, while in packaging, HDPE is often the material of choice for bottles and containers due to its durability and resistance to impact. Additionally, the agricultural industry benefits from HDPE sheets in applications such as greenhouse covers and liners.

In conclusion, the density of HDPE sheets is a critical factor that influences their functionality and application across various industries. Understanding these properties allows manufacturers, engineers, and consumers to make informed decisions about the use of HDPE in their projects, ensuring optimal performance and longevity. As industries continue to evolve, HDPE remains a reliable and versatile choice, reinforcing its position in modern manufacturing and sustainability efforts.

-

High-Quality PPR Pipes and Fittings Durable ERA PPR & PVC PPR Solutions

NewsJul.08,2025

-

Black HDPE Cutting Board - Durable, Non-Porous & Food Safe HDPE Plastic Cutting Board

NewsJul.08,2025

-

High-Quality CPVC Panel Durable HDPE & PVC Panels Supplier

NewsJul.08,2025

-

Double PE Welding Rod Supplier - High Strength, Durable & Versatile Welding Solutions

NewsJul.07,2025

-

High-Quality PVC-O Pipe Supplier Durable 75mm PVC Pipe & Connections Leading PVC Pipe Company

NewsJul.07,2025

-

HDPE Drainage Pipe Supplier – Durable & Corrosion-Resistant Solutions

NewsJul.06,2025